Medical guide wire fixing fixture and guide wire welding equipment

A technology for fixing fixtures and guide wires, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as the inability to clamp and position medical guide wires, improve installation convenience and installation accuracy, improve fixation accuracy and The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

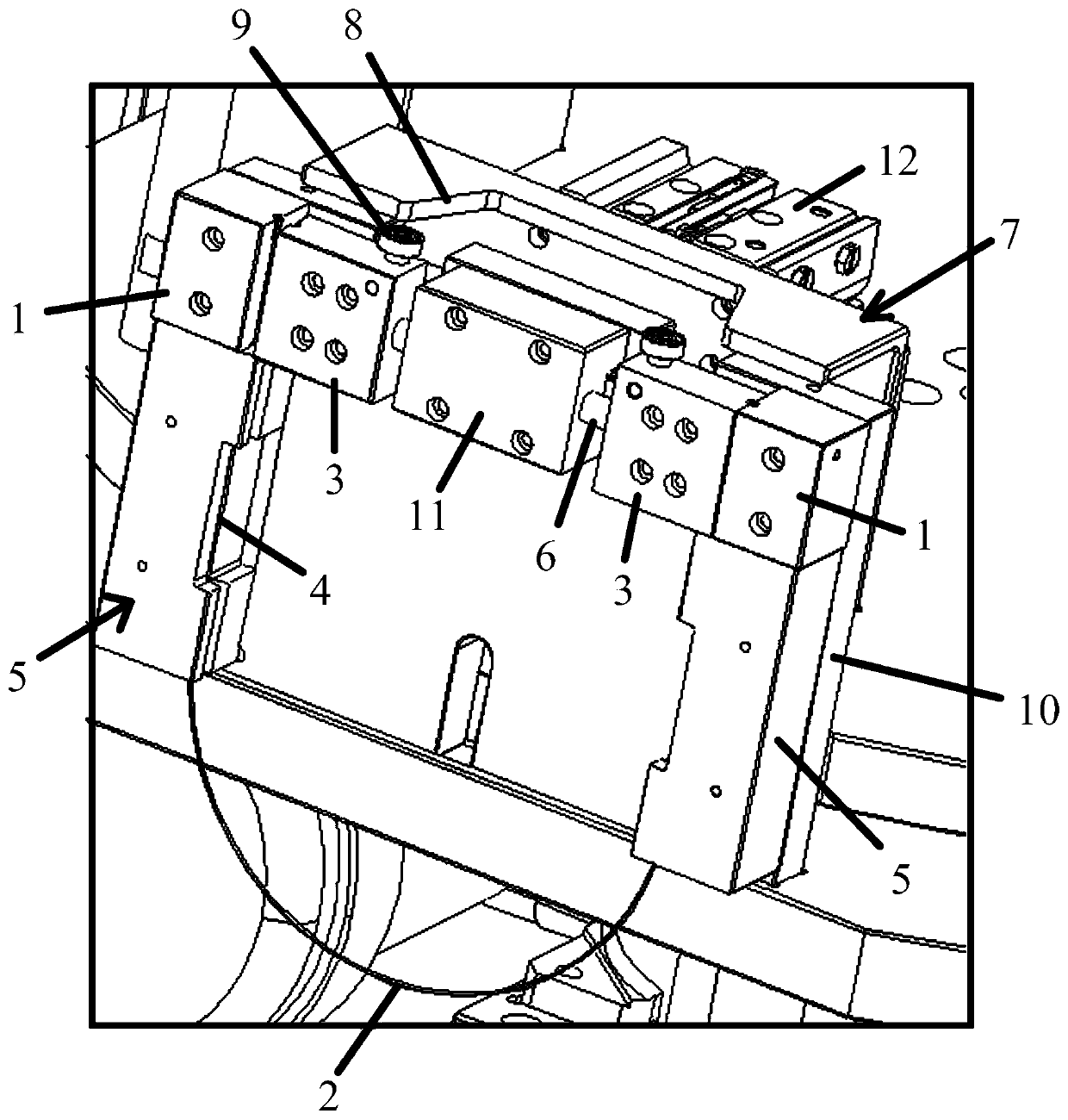

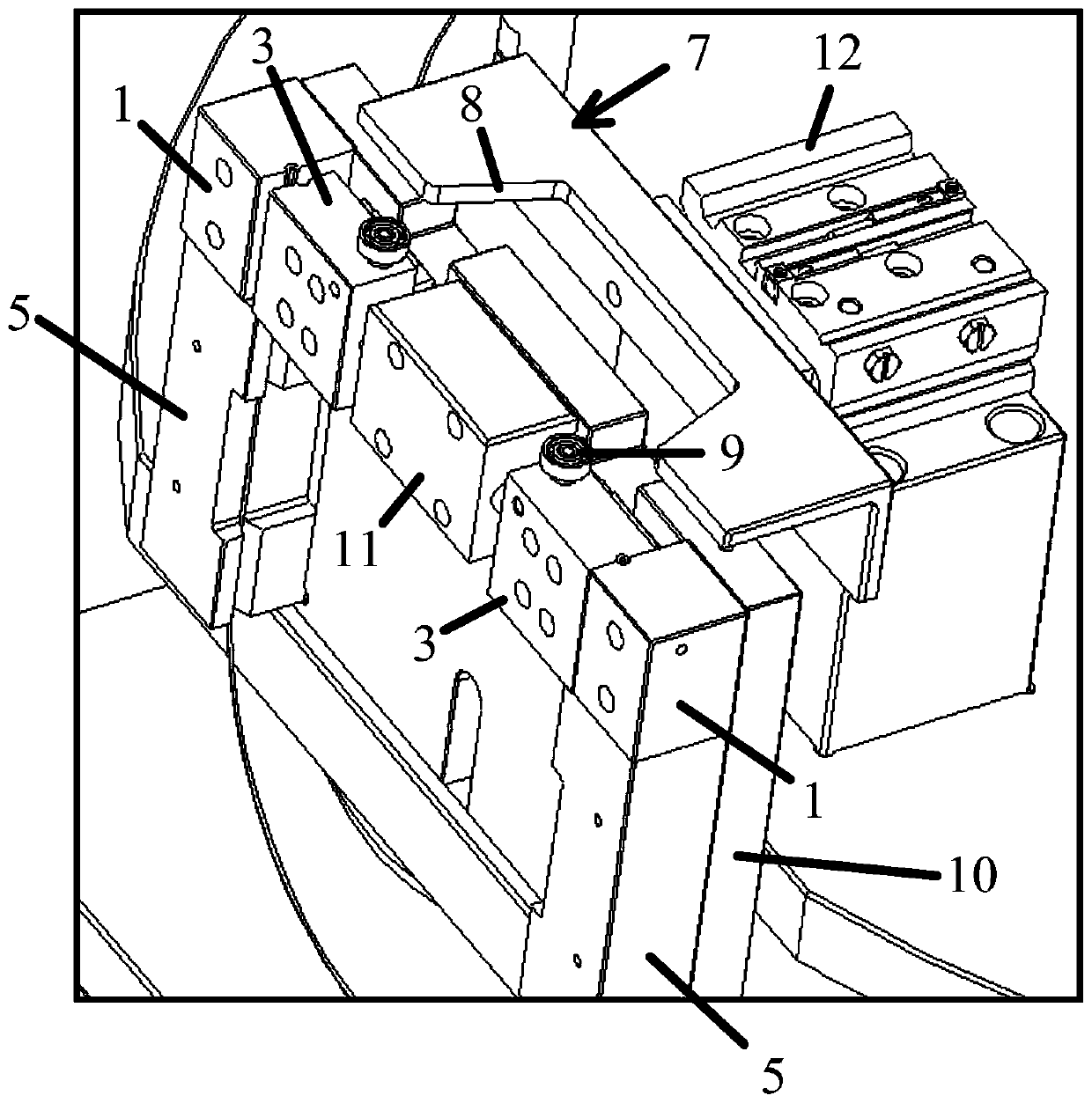

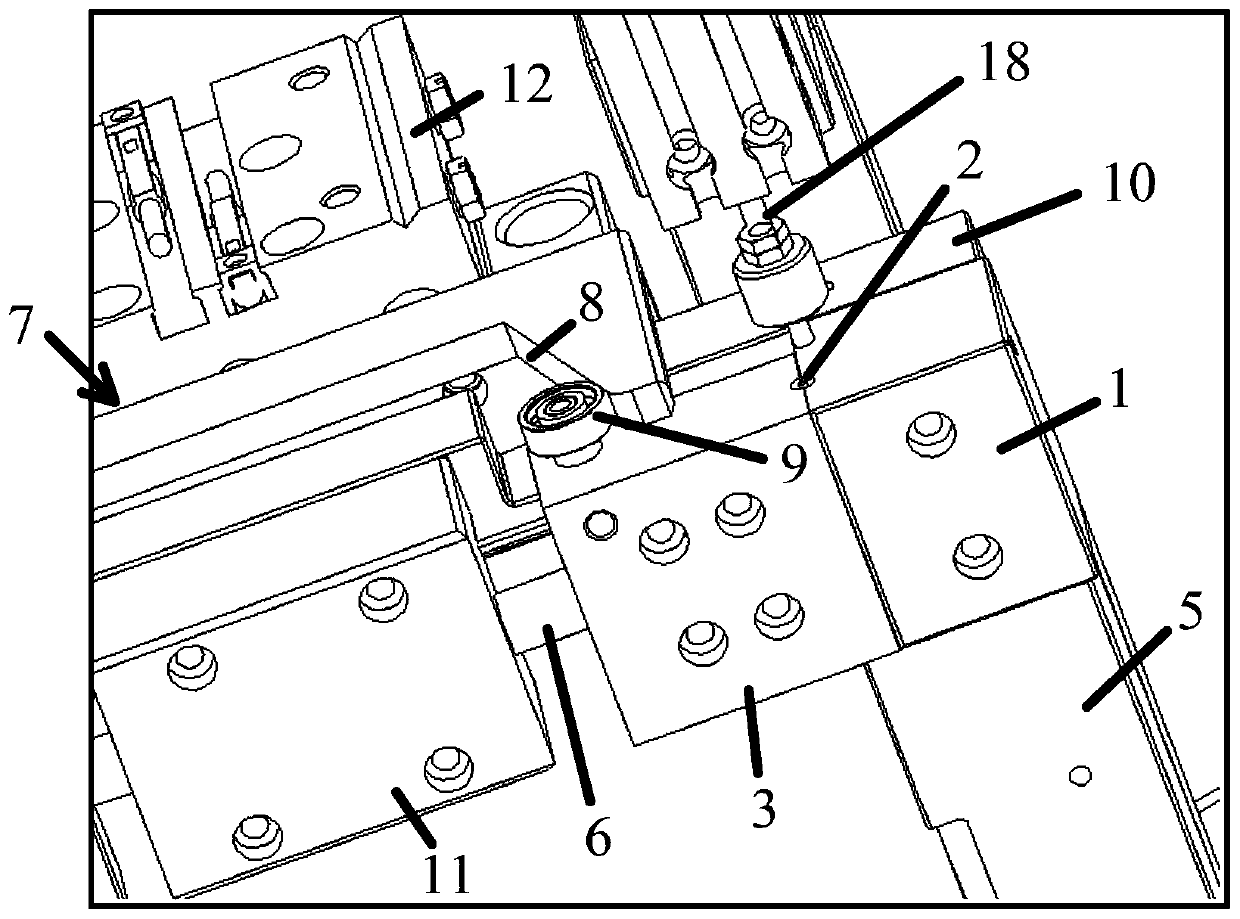

[0051] This embodiment provides a guide wire welding equipment, such as Figure 4 and Figure 5 shown, which includes:

[0052] Guidewire fixing device 17, used to fix the medical guidewire 2;

[0053] Welding mechanism 13;

[0054] There are 4 guide wire fixing devices 14 on the rotating base 14, and they are arranged on the rotating base 14; the rotating base 14 is driven to rotate, and the 4 medical guide wire fixing fixtures with the medical guide wire 2 are moved sequentially to the processing station of the welding mechanism 13;

[0055] The welding equipment base 15, the above-mentioned medical guide wire fixing fixture is arranged on the welding equipment base 15 through the rotating seat 14; there are four guide wire fixing devices 17, which are evenly distributed on the rotating seat 14 of the circular structure;

[0056] The protective cover 16 is arranged on the rotating base 14 , and the protective cover 16 is respectively provided with openings at positions f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com