A Controlled Rolling Method for Eliminating Chromatic Defects on the Surface of Hot-rolled Strip Steel

A technology for controlling rolling and hot-rolled steel strips, applied in rolling mill control devices, metal rolling, metal rolling, etc. Avoid and improve the effect of descaling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking the low-carbon steel DC04 as the target steel grade, the purer molten steel is obtained through smelting, and then continuously cast into a billet through a continuous casting machine. The composition weight percentage is: C: 0.039%, Si: 0.025%, Mn: 0.23%, P: 0.017%, S: 0.0045%, Al: 0.022%, and the balance is iron.

[0041] The thickness of the cast slab is 200mm, and the cast slab is heated in a heating furnace for 180min. In the process of descaling in 1, 3 and 5 passes, the hydraulic pressure of rough rolling and descaling is 18MPa, and the temperature of rough rolling and final rolling is controlled at 1040°C;

[0042] Dephosphorize the slab entering the finishing mill once, and the dephosphorization water pressure is 18MPa, and then carry out the finish rolling with 7 stands. The starting temperature of the finish rolling stage is 1030°C. The cooling water volume between the racks is 60%, the cooling water volume between the second and third racks is 50%, t...

Embodiment 2

[0046] Taking low-carbon steel SPHC as the target steel grade, pure molten steel is obtained through smelting, and then continuously cast into billets through continuous casting machines. The composition weight percentages are: C: 0.05%, Si: 0.03%, Mn: 0.33%, P: 0.015%, S: 0.004%, Al: 0.02%, and the balance is iron.

[0047] The thickness of the cast slab is 220mm, and the cast slab is heated in a heating furnace for 200min. In the process of descaling in 1, 3 and 5 passes, the water pressure for rough rolling and descaling is 20MPa, and the temperature for rough rolling and final rolling is controlled at 1080°C;

[0048] Dephosphorize the slab entering the finishing mill once, the water pressure of the finishing mill is 20MPa, and then carry out the finish rolling of 7 stands. The cooling water volume between the second rack is 65%, the cooling water volume between the second and third racks is 55%, the cooling water volume between the third and fourth racks is 45%, and the ...

Embodiment 3

[0052] Taking alloy steel 510L as the target steel type, pure molten steel is obtained through smelting, and then cast into slabs through continuous casting machines. The composition weight percentages are: C: 0.08%, Si: 0.15%, Mn: 1.3%, P : 0.018%, S: 0.005%, Al: 0.02%, Nb: 0.024%, and the balance is iron.

[0053] The thickness of the cast slab is 240mm, and the cast slab is heated in a heating furnace for 220min. In the process of descaling in 1, 3 and 5 passes, the water pressure of rough rolling and descaling is 22MPa, and the temperature of rough rolling and final rolling is controlled at 1100°C;

[0054] Dephosphorize the slab entering the finishing mill once, and the dephosphorization water pressure of the finishing mill is 22MPa, and then carry out the finish rolling of 7 stands. The cooling water volume between the second rack is 70%, the cooling water volume between the second and third racks is 60%, the cooling water volume between the third and fourth racks is 40...

PUM

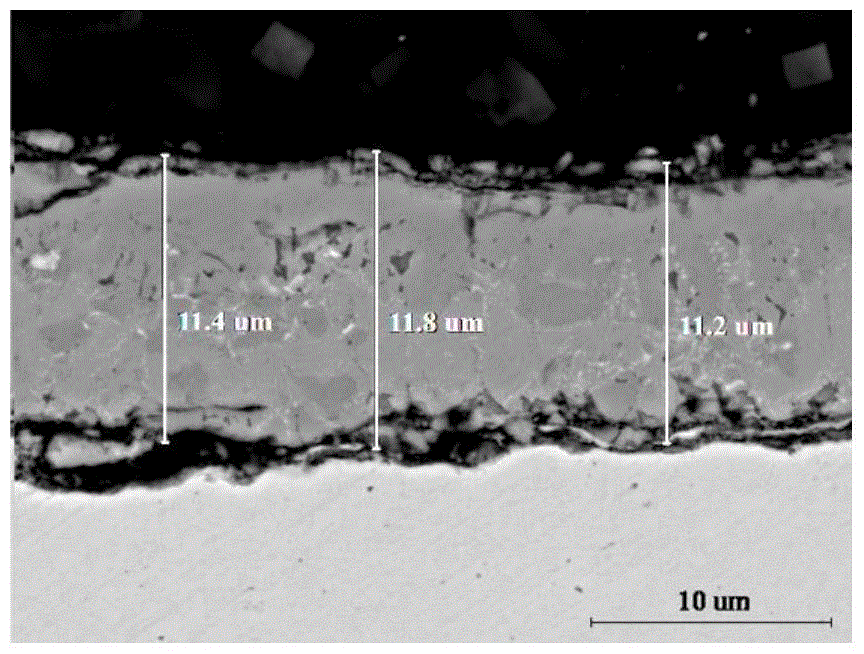

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com