Organic-inorganic double-shell microcapsule for temperature-controlled release of hydrophobic micromolecules and preparation method thereof

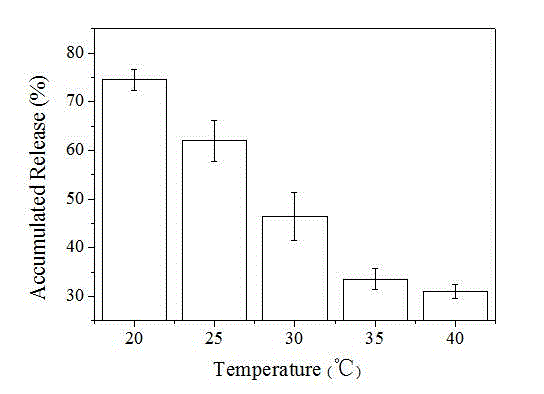

A hydrophobic and microcapsule technology, which is applied in the field of responsive microcapsules and its preparation, to achieve obvious temperature-controlled release ability and high sustained-release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

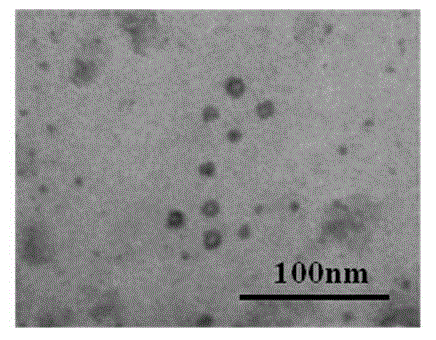

Image

Examples

preparation example Construction

[0031] The preparation method of the organic-inorganic double-shell microcapsules used for temperature-controlled release of hydrophobic small molecules according to the present invention comprises the following steps:

[0032] Step 1: Add 30-60 mg of amphiphilic tri-block copolymer, 20-40 μL of silica precursor, 3-9 μL of silane coupling agent and 5-15 mg of hydrophobic small molecule substances into 600-800 μL of organic solvent at the same time, After stirring and dissolving at room temperature for 5-10 h, a mixed solution was obtained.

[0033] Step 2: Weigh 90-150 mg of chitosan powder, add it to 15-30 mL of weak acid solution with a mass fraction of 1-3%, stir and dissolve at 30-50°C for 10-40 hours, then cool to room temperature, that is Obtain chitosan solution.

[0034] Step 3: At room temperature, gradually add 400-600 μL of the mixed solution obtained in Step 1 to 10-20 mL of chitosan solution, and the time for adding is 40-60 minutes. During the process of adding,...

Embodiment 1

[0047] Step 1: Add 30 mg of amphiphilic triblock copolymer, 40 μL of silica precursor, 3 μL of silane coupling agent and 15 mg of hydrophobic small molecular substance into 600 μL of organic solvent at the same time, stir and dissolve at room temperature for 10 hours to obtain a mixed solution .

[0048] Step 2: Weigh 90 mg of chitosan powder, add it to 30 mL of weak acid solution with a mass fraction of 1%, stir and dissolve at 50° C. for 10 h, and cool to room temperature to obtain a chitosan solution.

[0049] Step 3: At room temperature, gradually drop 600 μL of the mixed solution obtained in Step 1 into 10 mL of chitosan solution for 60 minutes. During the dropping process, the chitosan solution is always in a stirring state.

[0050] After the dropwise addition was completed, ultrasonic treatment was performed for 5 minutes and continuous stirring was continued for 60 hours to obtain organic-inorganic double-shell microcapsules for temperature-controlled release of hydro...

Embodiment 2

[0062] Step 1: Add 40 mg of amphiphilic triblock copolymer, 35 μL of silica precursor, 5 μL of silane coupling agent and 13 mg of hydrophobic small molecular substance into 660 μL of organic solvent at the same time, stir and dissolve at room temperature for 9 hours, and obtain a mixed solution .

[0063] Step 2: Weigh 110 mg of chitosan powder, add it to 25 mL of weak acid solution with a mass fraction of 1.5%, stir and dissolve at 42° C. for 20 h, and cool to room temperature to obtain a chitosan solution.

[0064] Step 3: At room temperature, 520 μL of the mixed solution obtained in Step 1 was gradually added dropwise to 13 mL of chitosan solution for 52 minutes. During the dropping process, the chitosan solution was always in a stirring state.

[0065] After the dropwise addition, ultrasonic treatment was performed for 8 minutes and continuous stirring was continued for 52 hours to obtain organic-inorganic double-shell microcapsules for temperature-controlled release of hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com