Machine for threading hot dog sausages with sticks

A technology of hot dog sausage and sticking, which is applied in slaughtering, skewering meat on skewers, meat processing equipment, etc. It can solve the problems of low degree of mechanization, low production efficiency, and high labor intensity, and achieve a high degree of mechanical automation , high production efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A hot dog sausage fixation mechanism

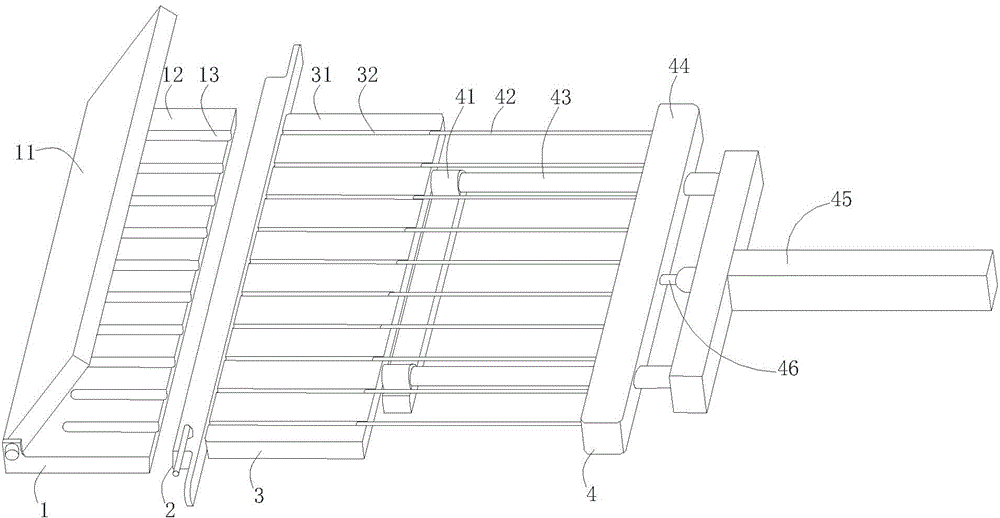

[0031] Such as figure 1 As shown in , the hot dog sausage fixing mechanism of this embodiment includes a first fixing plate 12 and a movable pressing plate 11 covering the first fixing plate 12, the movable pressing plate 11 is hinged to the first fixing plate 12 through a rotating shaft, Ten hot dog sausage fixing slots 13 are arranged side by side on the side of the first fixing plate 12 away from the rotating shaft.

Embodiment 2

[0032] Embodiment 2: A kind of bamboo stick clamping mechanism

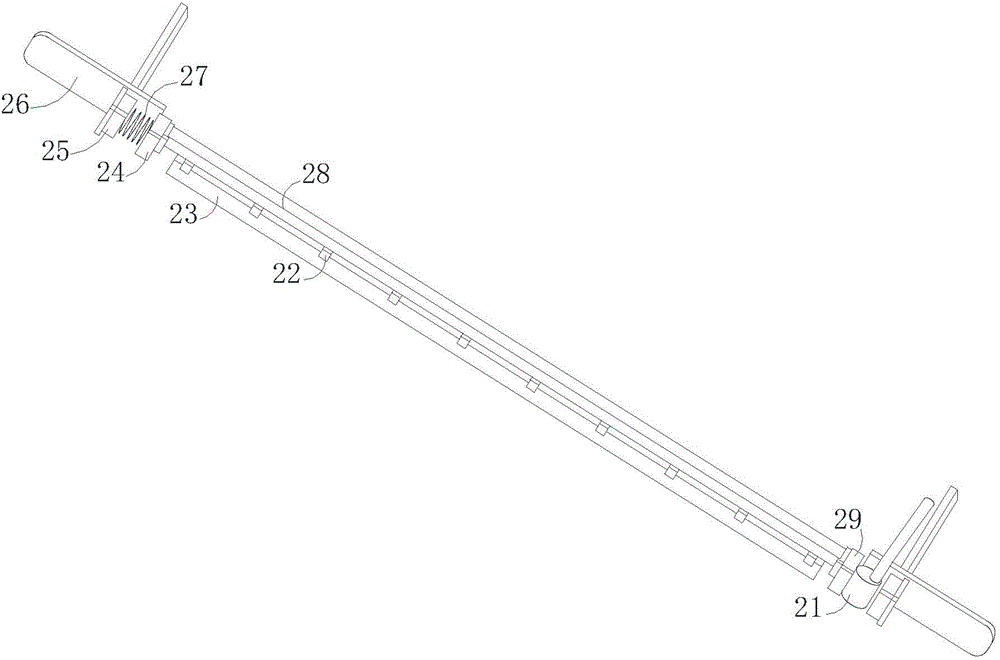

[0033] Such as Figure 3 ~ Figure 5 As shown, the bamboo stick clamping mechanism of the present embodiment includes two fixed mounts 26 facing to each other. One of the fixed mounts 26 includes a fixed block 25 fixedly connected thereto. The fixed block 25 is fixedly connected to one end of the spring 27. ; The other fixed frame is provided with an eccentric wheel 21, and the eccentric wheel 21 is fixedly connected with a manual handle; the other end of the spring 27 is fixedly connected with a connecting block one 24, and the connecting block one 24 is connected with the second movable One end of the plate 28 is fixedly connected, and the other end of the second movable plate 28 is fixedly connected with a connecting block two 29, and the connecting block two 29 is close to the eccentric wheel 21, and the eccentric wheel 21 can push the eccentric wheel 21 when it rotates eccentrically. The second connecting bl...

Embodiment 3

[0034] Embodiment 3: A kind of bamboo stick pressure feeding mechanism

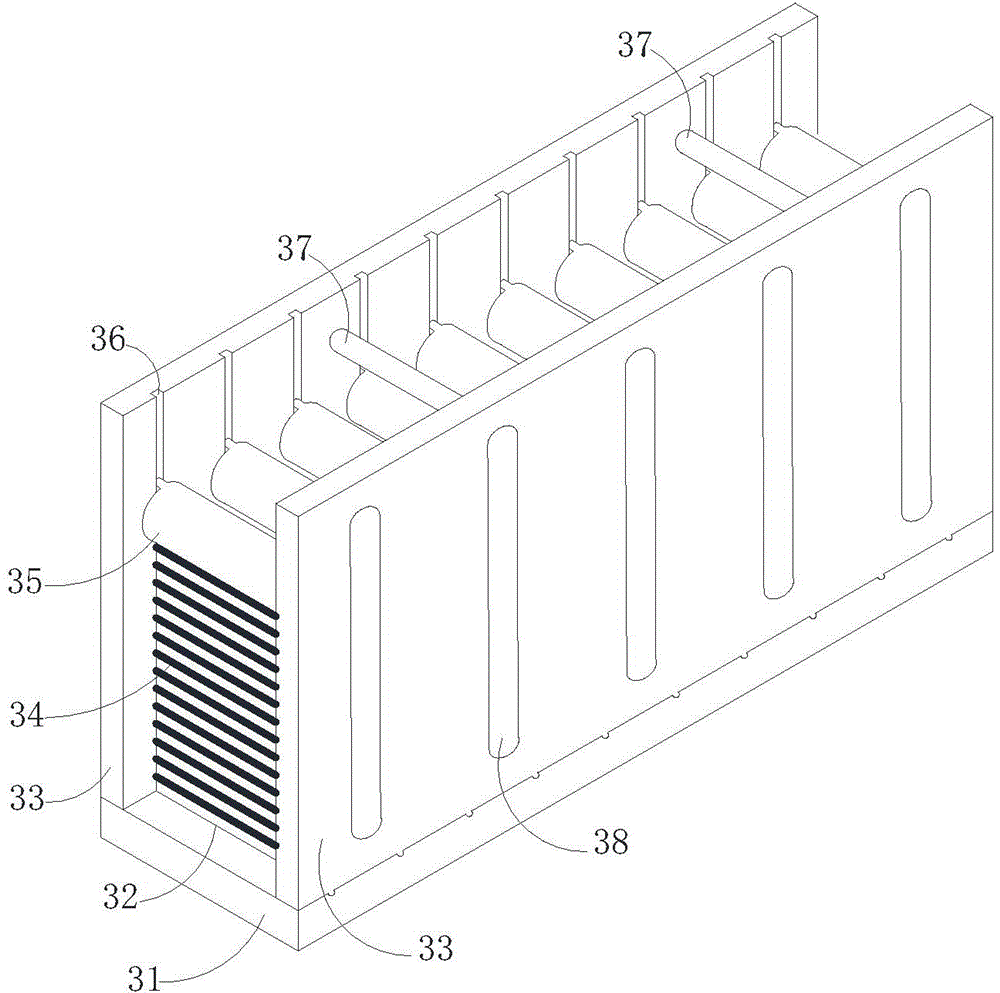

[0035] Such as Figure 1 ~ Figure 2 As shown, the bamboo stick pressure feeding mechanism of the present embodiment comprises a guide base plate 31 and two bamboo stick splints 33, and ten bamboo stick chute 32 is arranged on the upper surface of the guide base plate 31, and the two bamboo stick splints 33 are respectively Fixedly arranged on the two ends of the guide base plate 31, the two bamboo stick splints 33 are vertically provided with a counterweight chute 36 corresponding to the bamboo stick chute 32 on their sides close to each other. A counterweight 35 that can slide up and down along the counterweight chute 36 is arranged between the two facing counterweight chute 36 . The upper ends of the two bamboo stick splints 33 are detachably fixedly connected by a positioning rod 37 , and the length of the positioning rod 37 is equal to the distance length between the bottom ends of the two bamboo sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com