Gas separation membrane

A gas separation membrane, general-form technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve problems such as chemical structure limitation, difficulty in designing chemical structure considering processability, strength and separation performance, etc. Excellent film properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0154] Hereafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples.

[0155] [Preparation of polyimide film]

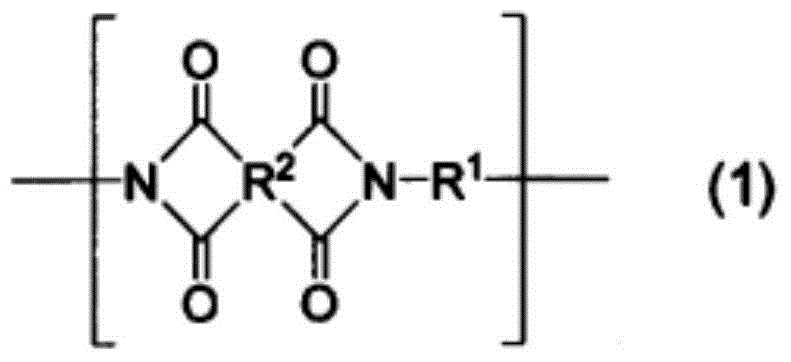

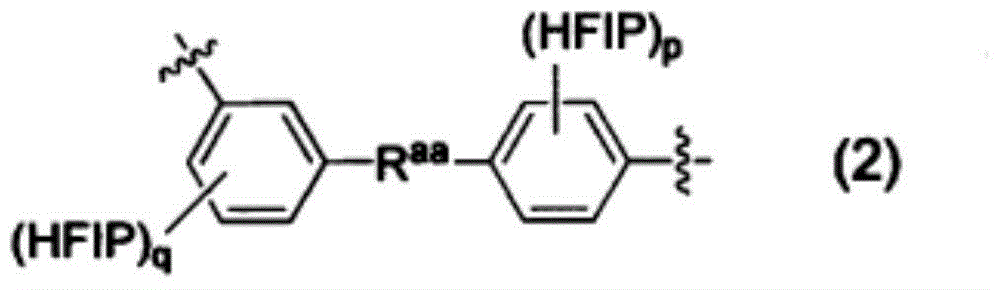

[0156] The preparation of the HFIP group-containing asymmetric polyimide membrane for the gas separation membrane will be described.

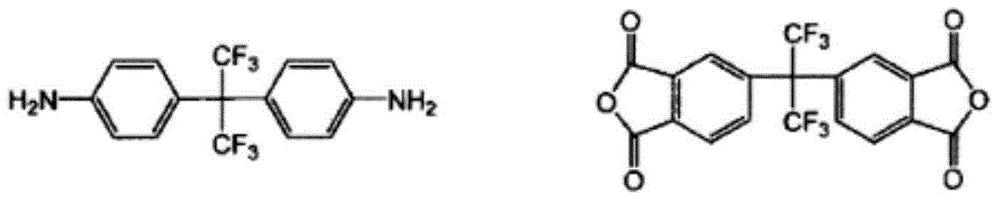

[0157] Add 2.01g (3.78mmol) of the following HFA-3,4'-ODA, 1.68g (3.78mmol) of 6FDA, and 14g of N,N-dimethylacetamide to a 200mL three-necked flask equipped with a nitrogen gas introduction tube and a reflux cooler, After stirring at room temperature under a nitrogen atmosphere for 18 hours, 0.66 g (8.32 mmol) of pyridine and 0.77 g (7.56 mmol) of acetic anhydride were added, and the mixture was further stirred at room temperature for 3 hours. The resulting reaction liquid was heated up to 200° C., stirred for further 6 hours, and then cooled to room temperature. A homogeneous N,N-dimethylacetamide solution in which polyimide 1 was dissolved was obtained. The Mw of the polyi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com