Reliability test method of tool magazine manipulator in machining center based on field load characteristics

A technology of machining centers and test methods, applied in computer control, instruments, simulators, etc., can solve problems that are not considered, fault data cannot be used for reliability evaluation, and tend to perform performance tests on tool magazine manipulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention is described in detail below in conjunction with accompanying drawing:

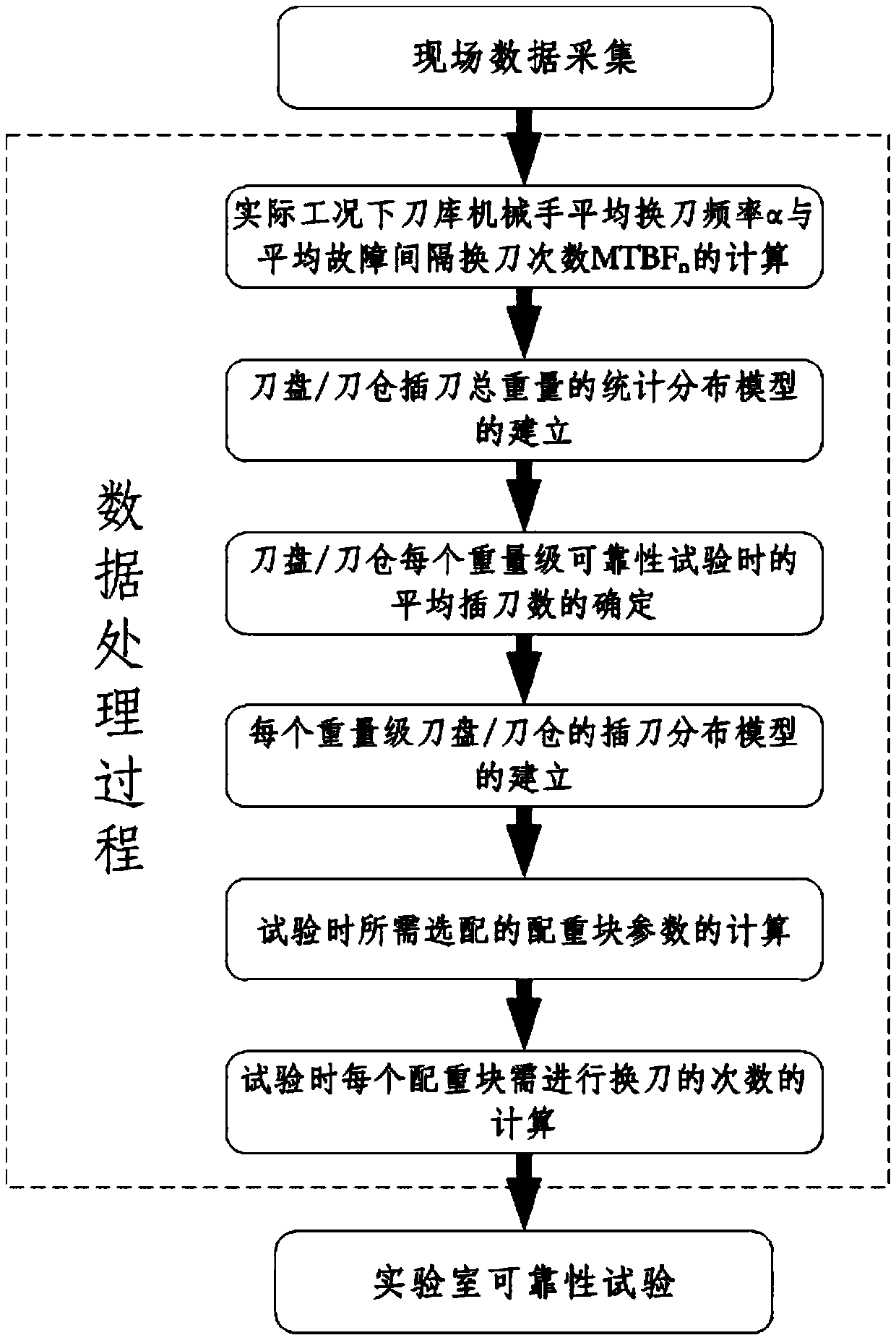

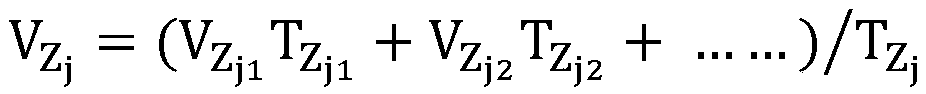

[0089] refer to figure 1 According to the present invention, the reliability test method of the machining center tool magazine manipulator based on field load characteristics includes three steps of field data collection, data processing and laboratory reliability test. The data processing process includes the average tool change frequency α of the tool magazine manipulator under actual working conditions and the mean number of tool changes between failures MTBF n Calculation of the total weight of the cutterhead / knife bin inserting the knife M i The establishment of the statistical distribution model, the average number of inserted knives for each heavyweight reliability test of the cutterhead / knife magazine The establishment of the knife insertion distribution model for each heavyweight cutterhead / knife bin, the calculation of the parameters of the optional counterweight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com