Grade braking type ceramic base brake pad system

A technology of base brake pads and ceramic bases, which is applied in the field of ceramic base brake pads, can solve the problems of large vehicle wear, poor choice of degrees of freedom, and collision damage by passengers, and achieve the effect of small wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

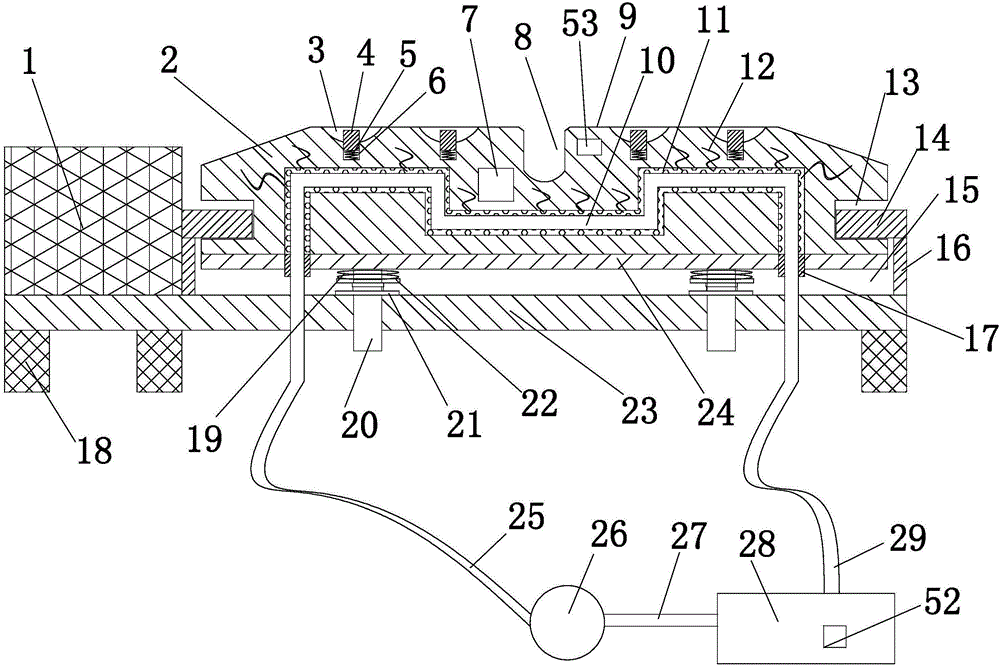

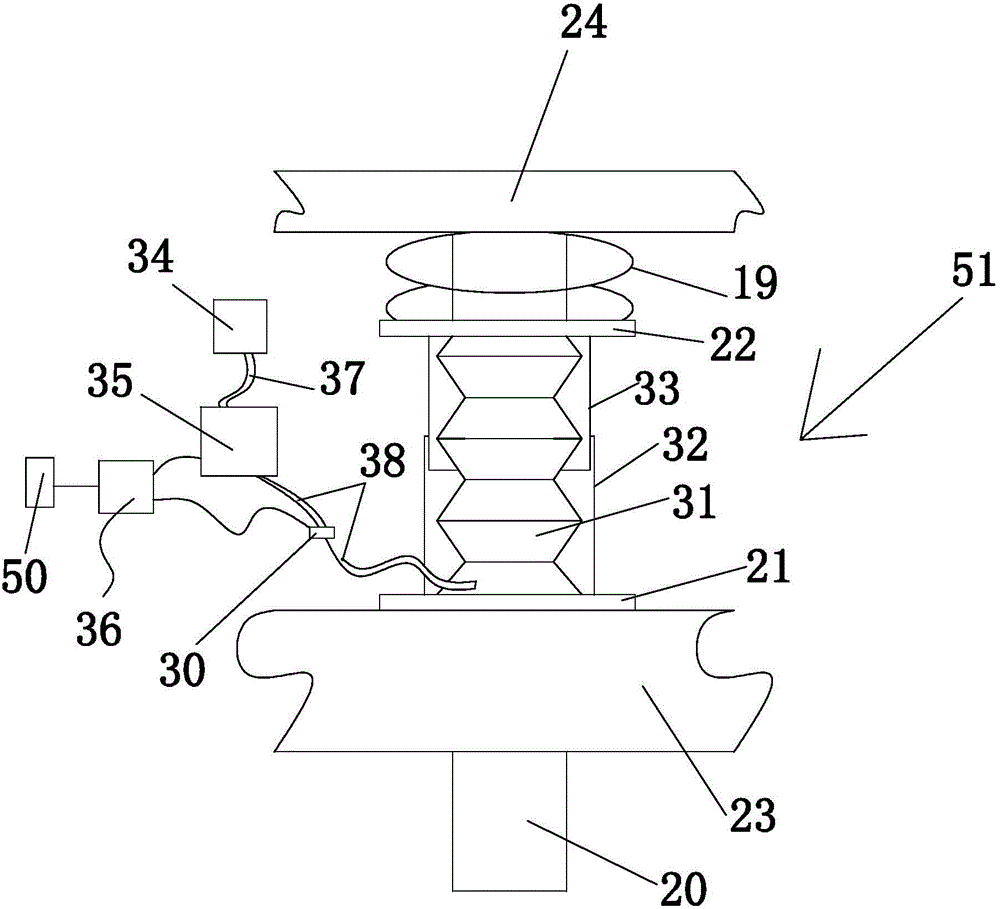

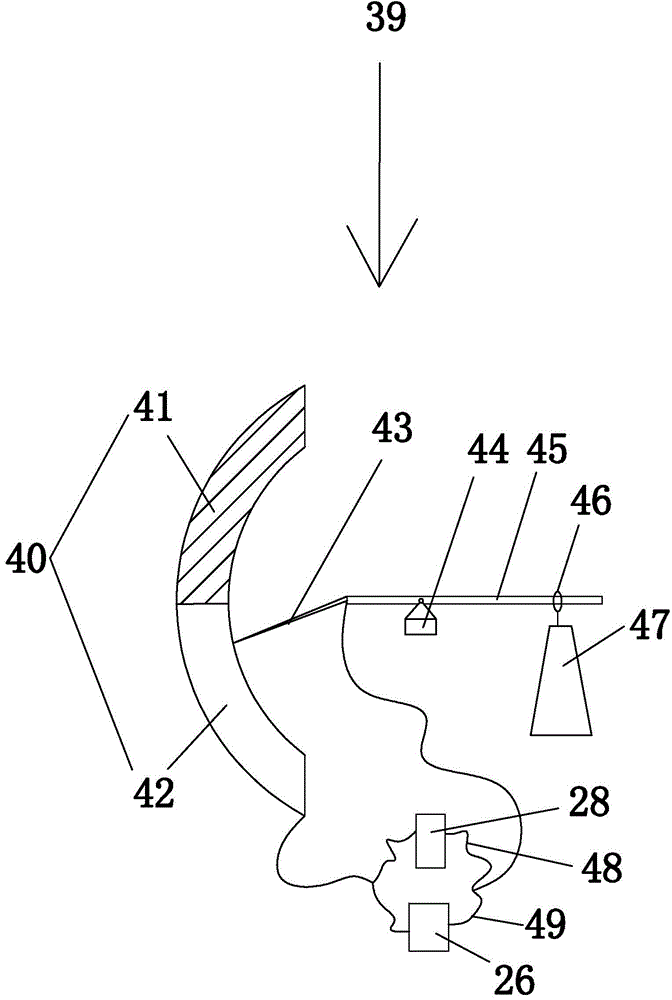

[0028] Embodiment, the hierarchical braking type ceramic-based brake pad system capable of cooling down, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a steel plate 23 provided with a mounting seat 18, a conventional brake ceramic-based friction plate 2, an emergency brake ceramic-based friction plate 1, two clamping blocks 16, a controller 36 and a conventional brake strength adjustment knob switch 50 ; The friction coefficient of the emergency brake ceramic-based friction plate is greater than that of the conventional brake ceramic-based friction plate; the emergency brake ceramic-based friction plate is fixedly connected to the left end surface of the upper surface of the steel plate, and the two clamping blocks are facing and fixedly connected On the upper surface of the steel plate on the right side of the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com