Method for preparing biological hydrogen by using traditional Chinese medicine residue

A traditional Chinese medicine slag and biological technology, which is applied in the field of gas fuel, can solve the problems of the amount of material gas, the instability of the system, and the uneven distribution of the bed, and achieve the effect of reducing the content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

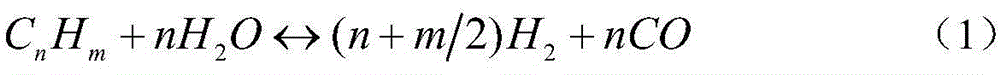

[0042] The method that the present invention proposes adopts the pyrolysis gasification reaction system prepared by Institute of Process Engineering, Chinese Academy of Sciences, see figure 1 . The system includes a pyrolyzer 1, a gasification bed 2, a primary cyclone separator 3, and a secondary cyclone separator 4. The bottom of the pyrolyzer 1 is provided with an air inlet 7 for the pyrolyzer, and the middle part is an inlet 6 for Chinese medicinal residues. The material outlet of the pyrolyzer is connected with the gasification bed 2 . The top of the gasification bed 2 is connected to the primary cyclone separator 3 and the secondary cyclone separator 4 through pipelines, and the two cyclone separators are connected in series. The air inlet 5 of the return valve at the bottom of the primary cyclone separator 3 is used to control the return of the heat carrier to the pyrolyzer. A gasification agent inlet 8 is provided at the bottom of the gasification bed 2 . The gas ou...

Embodiment 2

[0063] System is the same as embodiment 1. The composition of traditional Chinese medicine dregs is as follows:

[0064] Table 6 Industrial analysis and elemental analysis of traditional Chinese medicine residues

[0065]

[0066] In step 2), the water vapor ratio is controlled at 0.7, and the equivalent oxygen ratio is controlled at 0.2.

[0067] In step 4), the temperature of the reforming reaction is 880-900 ° C, the pressure is 2.8 MPa, and the molar ratio of water vapor to C is controlled at 3.3; the reformed gas is first cooled to 370 ° C by a cooler, and enters the high-temperature conversion reaction After the conversion reaction is carried out in the high-temperature conversion reactor, it is cooled to 200°C and then enters the low-temperature conversion reactor for conversion reaction. Hydrogen is purified by pressure swing adsorption device, and the recovery rate of hydrogen is 96%.

[0068] All the other operating parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com