Method for hydrothermal method preparation of graphene-loaded flower-type titanium dioxide composite material

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as complex processes, and achieve the effects of simple process, promotion of transmission, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of graphite oxide: Weigh 1.5g flake graphite and mix with 4.5g potassium permanganate, add 180mL to the mixed acid solution of sulfuric acid and phosphoric acid (volume ratio 9:1), stir and react at 30~40℃ for 1h Afterwards, the temperature was raised to 50° C. to continue the reaction for 12 h. Cool to room temperature after the reaction, slowly pour the reaction product into ice water containing 10mL hydrogen peroxide, let it stand, pour off the supernatant, filter with suction, and wash the filter cake with 5% hydrochloric acid until there is no SO in the filtrate. 42- , followed by alternating washing with deionized water and ethanol to neutrality, and vacuum drying at 50°C for 12-24 hours to obtain the required graphite oxide.

[0035] (2) Preparation of graphene / flower-like titanium dioxide composite material: Weigh 8 mg of graphite oxide and add it to a mixed solution of 20 ml of ethylene glycol and 20 ml of water, and sonicate for 10-24 hours; S...

Embodiment 2

[0037] (1) The preparation of graphite oxide is the same as in Example 1.

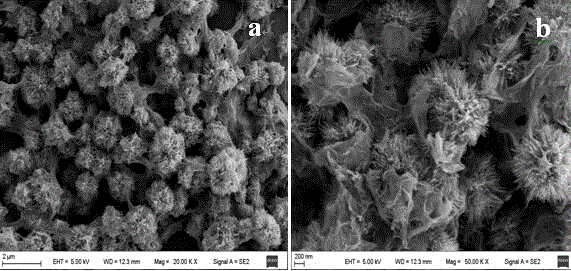

[0038] (2) Preparation of graphene / flower-like titanium dioxide composite material: Weigh 12 mg of graphite oxide and add it to a mixed solution of 30 ml of propanol and 10 ml of water, and sonicate for 10-24 hours. After the graphite oxide is homogenized by ultrasonication, 5 ml of an aqueous solution of polyvinylpyrrolidone with a concentration of 8 mg / ml is added thereto, and stirred for 1 h. Measure 0.5ml of titanium isopropoxide and add dropwise to 5ml of concentrated hydrochloric acid, stir and mix evenly, then add dropwise to the above graphite oxide solution, and continue to stir for 2h. Then the solution was added to a 100ml polytetrafluoroethylene reactor, reacted at 150°C for 24h, cooled to room temperature, filtered, washed, and dried to obtain a graphene-loaded flower-shaped titanium dioxide composite material. The graphene in the product is flat, and the size distribution of the flower-l...

Embodiment 3

[0040] (1) The preparation of graphite oxide is the same as in Example 1.

[0041] (2) Preparation of graphene / flower-like titanium dioxide composite material: Weigh 8 mg of graphite oxide and add it to a mixed solution of 20 ml of ethylene glycol and 20 ml of water, and sonicate for 10-24 hours; 8mg / ml cetyltrimethylammonium bromide aqueous solution, stir for 1h; measure 0.5ml titanium isopropoxide and add dropwise to 5ml concentrated hydrochloric acid, stir and mix evenly, then add dropwise to the alcoholic aqueous solution of graphite oxide , continue to stir for 2h, then add it into a 100ml polytetrafluoroethylene reactor, react at 180°C for 20h, cool to room temperature, filter, wash, and dry to obtain a graphene-loaded flower-shaped titanium dioxide composite material. Characterization found that the flower-shaped titanium dioxide in the composite material with a diameter of about 3-4um is composed of nanorods with a diameter of 35nm and a length of about 680nm, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com