Tensile heat-radiating graphite patch

A graphite patch, anti-stretch technology, applied in the direction of film/sheet adhesive, cooling/ventilation/heating modification, modification through conduction heat transfer, etc., can solve uneven heat dissipation, overheating of tape, reliability Poor performance and other problems, to achieve the effect of improving flatness and flexibility, improving biaxial tensile properties, and overcoming excessive heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

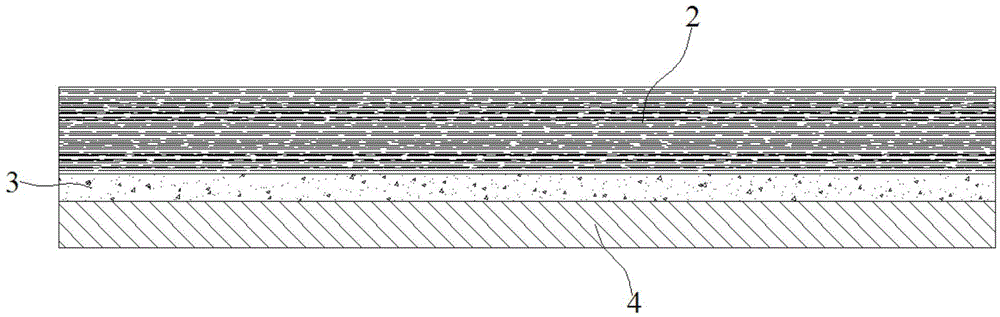

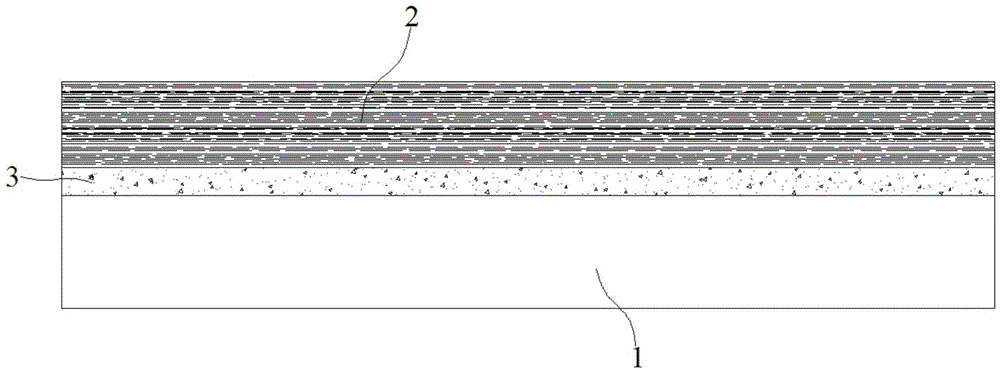

[0035] Embodiment: A stretch-resistant heat-dissipating graphite patch, the stretch-resistant heat-dissipating graphite patch is attached to the surface of the heating component 1, and the stretch-resistant heat-dissipating graphite patch includes a graphite layer 2, a graphite layer located on the surface of the graphite layer 2 A thermally conductive adhesive layer 3 and a release material layer 4, the release material layer 4 is attached to the surface opposite to the thermally conductive adhesive layer 3 and the graphite layer 2; the graphite layer 2 is obtained by the following process, which includes The following steps:

[0036] Step 1, the upper and lower surfaces of the polyimide film are coated with a graphite modifier to obtain a treated polyimide film, the viscosity of the graphite modifier is 30000 ~ 48000CP;

[0037] Described graphite modifier is made up of the component of following parts by weight, as shown in table 1:

[0038] Table 1

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com