Permanent magnet direct drive wind turbine, system and its stator

A technology of wind power generator and permanent magnet direct drive, which is applied in the direction of wind power generator, wind power motor combination, wind power generation, etc. It can solve the problems of affecting the service life, pressure resistance level and life reduction, insulation damage, etc., to prolong the service life, The effect of preventing the reduction of the insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

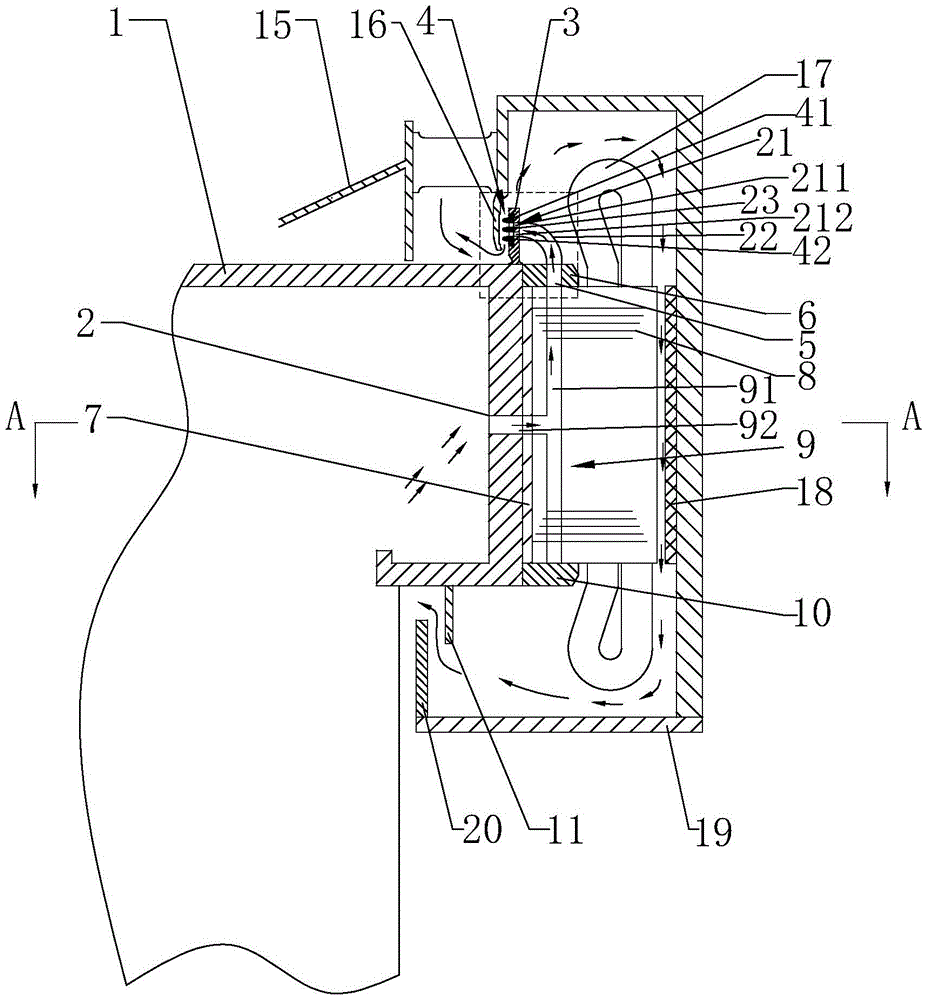

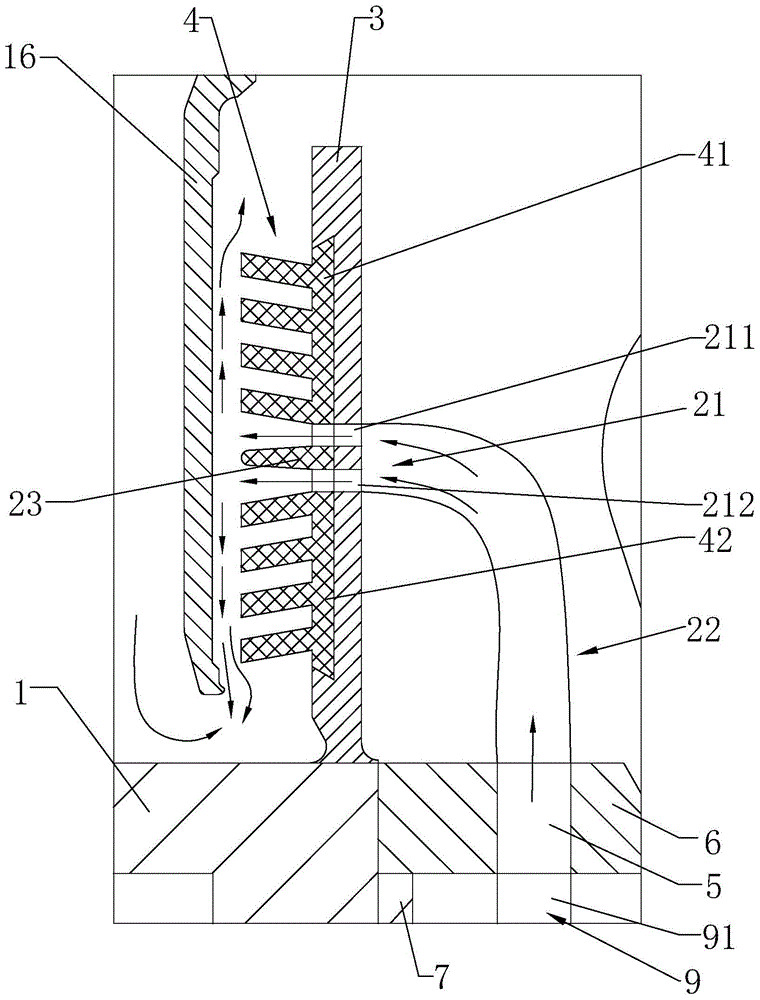

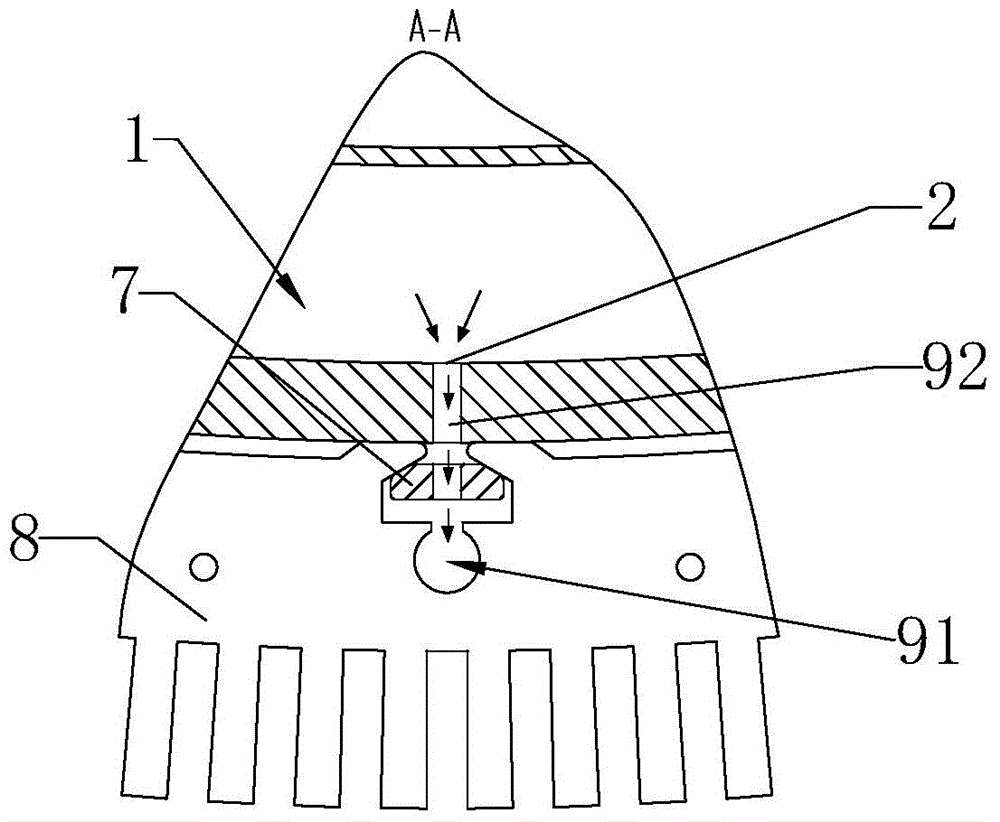

[0078] Such as figure 1 As shown, it is a schematic structural view of the stator of the permanent magnet direct drive wind power generator according to Embodiment 1 of the present invention. For ease of description, the figure 1 The upper part of the formula is defined as the propeller side (in the process of fan operation, the propeller side generally faces the upwind side), the lower part is defined as the tower side (in the process of fan operation, the tower side generally faces the downwind side), and the horizontal The direction is defined as radial direction (radial direction centering on the whole wind turbine), and the vertical direction is defined as axial direction (direction along the rotation axis of the wind turbine). In addition, the outer peripheral wall of the stator bracket 1 refers to the side wall that is in contact with or adjacent to the stator core 8 or the stamping key 7 that fixes the stator core 8 , that is, the outermost part of the stator bracket ...

Embodiment 2

[0118] On the basis of Embodiment 1, the stator of this embodiment is also provided with a helical comb mechanism on the tower side shroud on the tower side. Specifically, such as Figure 6 and Figure 7 as shown, Figure 6 It is a schematic diagram of the stator structure of the permanent magnet direct drive wind power generator according to the second embodiment of the present invention, Figure 7 for Figure 6 A schematic diagram of the local structure. In the direction of the tower side, the stator also includes a tower side tooth pressure plate 10 and a tower side coaming plate 11. The tower side tooth pressure plate 10 is arranged on the tower side axial end face of the stator core 8. Correspondingly, the rotor bracket 15 also has an end cover. The sealing ring 20, an annular gap is formed between the end cover sealing ring 20 and the tower side coaming plate 11.

[0119] A second spiral comb mechanism 24 is also provided on the side of the paddle side shroud 3 clos...

Embodiment 3

[0124] This embodiment relates to a permanent magnet direct drive wind power generator, including a rotor and a stator described in the first or second embodiment above.

[0125] In addition, this embodiment also provides a permanent magnet direct drive wind power generator system, which includes the above wind power generator and an air source system 12 arranged inside the wind turbine, and the air source system 12 can be connected to the first air hole 2 . Wherein, as an optional implementation manner, the gas source system 12 and the components associated with the gas source system 12 are also described in the first embodiment above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com