Residual intensity and residual life computing method for pipe gallery pipelines

A calculation method and pipeline technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effects of reducing the incidence of accidents, ensuring safe and efficient operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

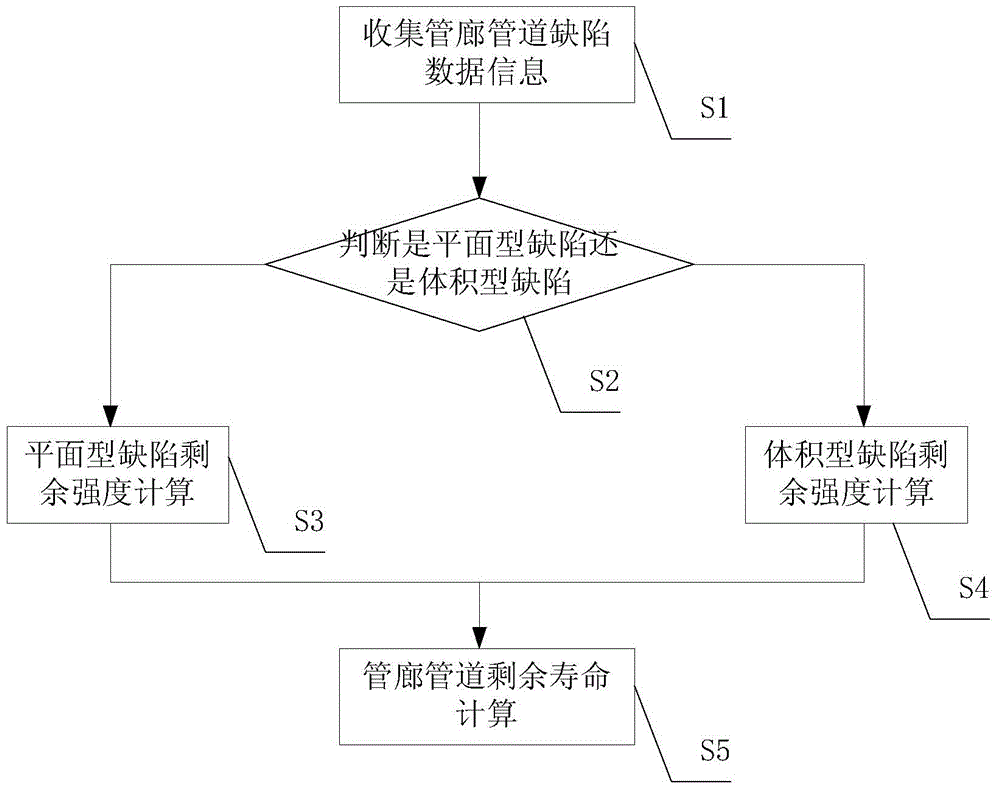

[0042] see figure 1 , the method for calculating the remaining strength and remaining life of the pipe gallery pipeline of the present invention includes the following steps:

[0043] Step S1, collecting data and information on pipeline defects in the pipeline gallery, including: basic pipeline information, pipeline structure and performance parameters, welding and temperature effects, stress-strain relationship of pipe materials, and crack forms of defects and other information.

[0044] Step S2, judging whether it is a planar defect or a volume defect, if it is a planar defect, perform step S3; if it is a volume defect, perform step S4;

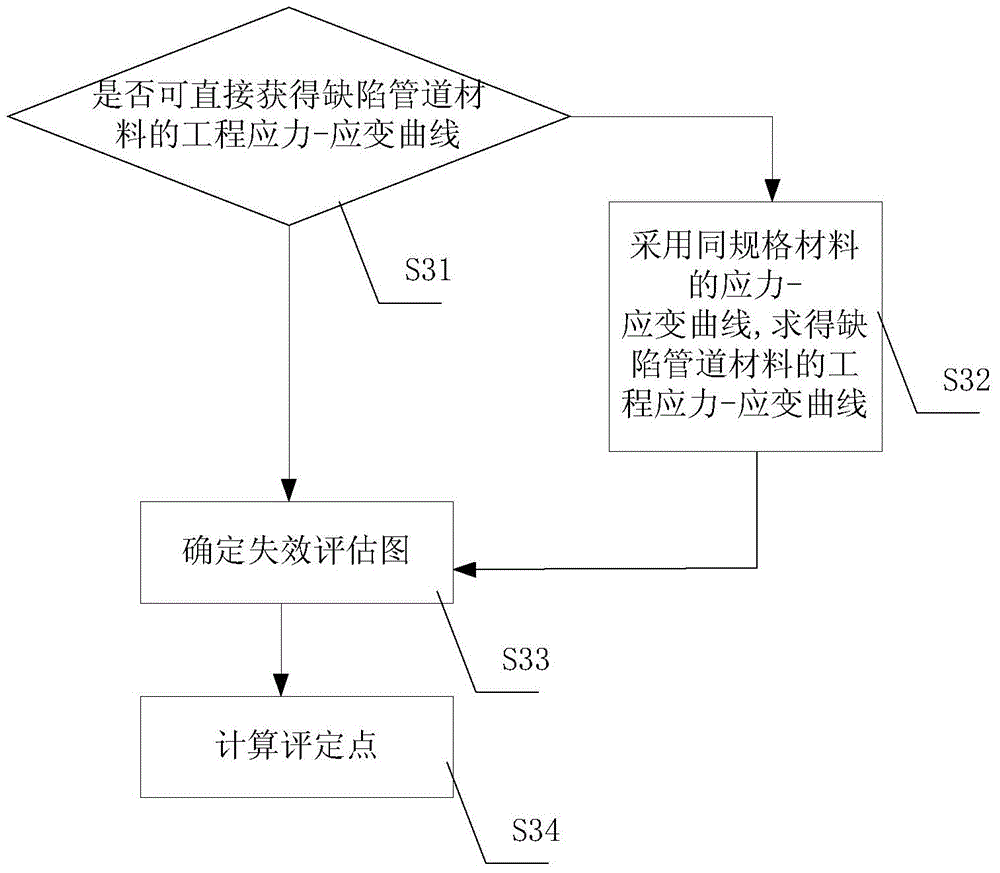

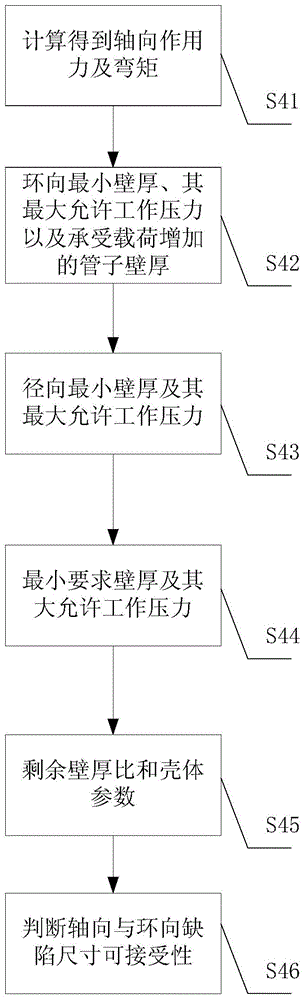

[0045] Step S3, for planar defects, obtain the engineering stress-strain curve of the defective pipe material from the defect data information of the pipe gallery, determine the failure evaluation diagram, and then calculate the evaluat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com