Valve wear test device

A wear test, valve technology, applied in the direction of testing wear resistance, etc., can solve problems such as difficult diagnosis of faults, complicated test process, leakage, etc., to achieve the effects of making up for easy leakage, avoiding lengthy cycles, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

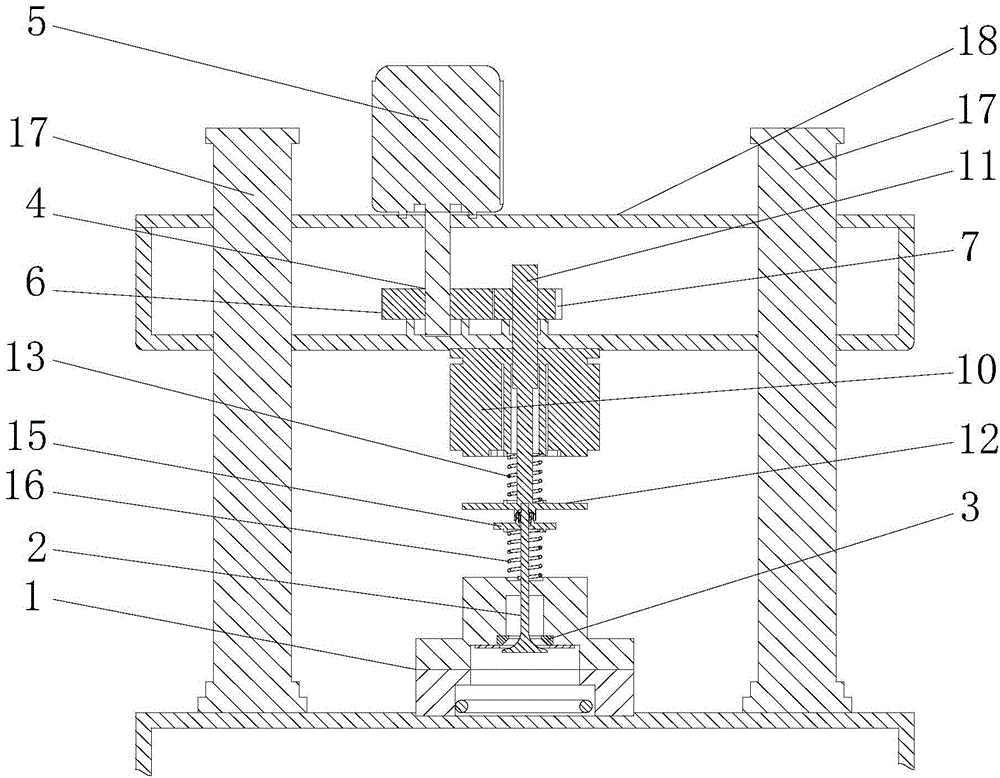

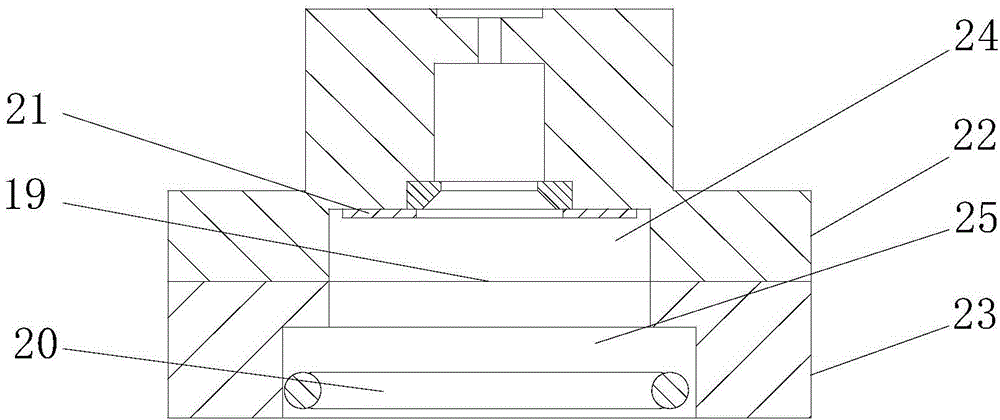

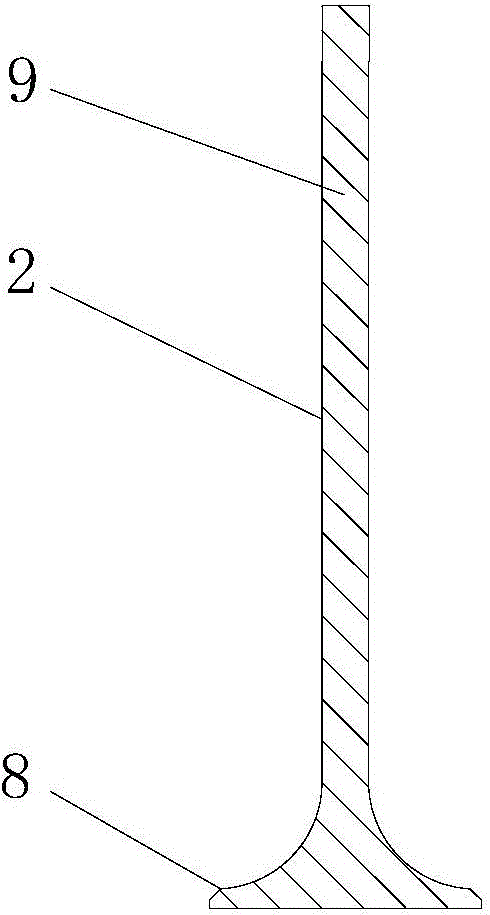

[0025] A valve wear test device includes a combustion chamber 1, a valve 2, a valve seat ring 3 and a rotating device 4 that drives the valve 2 to rotate, the rotating device includes a motor 5, a driving gear 6 and a driven gear 7, the The motor is connected to the driving gear, the driving gear is meshed with the driven gear, the driving rod is connected to the driven gear, the valve seat is arranged in the combustion chamber, and the valve passes through the valve seat Protruding into the combustion chamber, the valve face of the valve is in contact with the valve seat ring during testing.

[0026] Preferably, it also includes an electromagnetic closing mechanism that keeps the valve face 8 of the valve in contact with the valve seat ring during the test, and the valve stem 9 of the valve extends out of the combustion chamber and is connected with the electromagnetic closing mechanism. Preferably, the electromagnetic closing mechanism includes a magnetic base 10, a driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com