Cooling system for container treatment assemblies

A component, water cooling technology, used in liquid handling, household refrigeration units, cooling fluid circulation units, etc., which can solve the problems of high maintenance work, confusion of processing technology, etc., to achieve the effect of reduced complexity and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

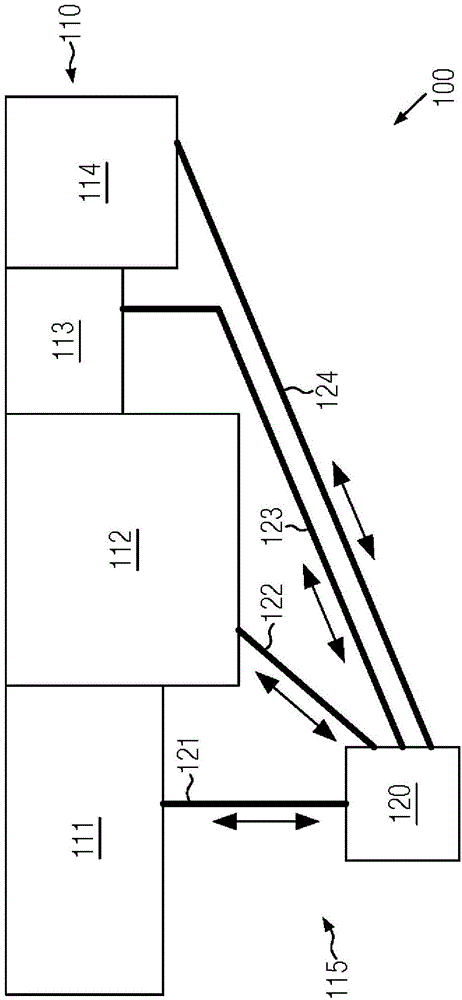

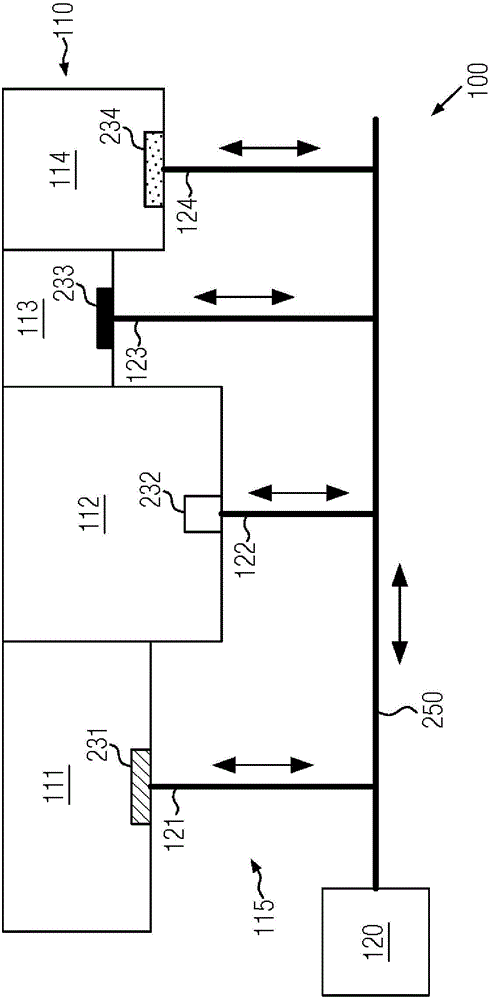

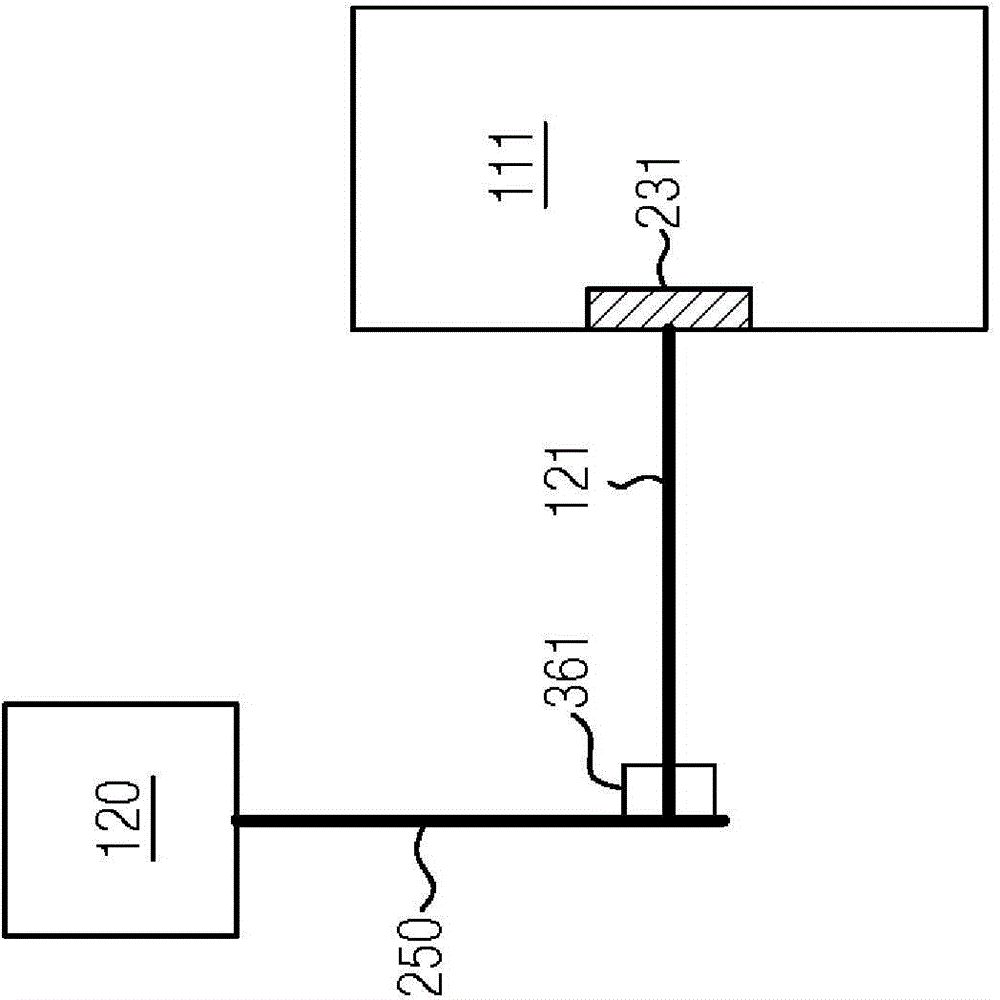

[0024] figure 1 A schematic diagram of an assembly 100 for the beverage processing industry according to the invention is shown. This assembly 100 includes: all the components for, for example, the production of containers, such as bottles, etc.; the components that allow labeling or further processing of the produced containers; and the components that complete the filling, sealing and packaging of the containers. The assembly 100 according to the invention comprises a plurality of individual devices combined to form an assemblage 110 .

[0025] These individual units 111-114 include at least blow molding machines, labeling machines and filling machines.

[0026] Other container handling devices such as direct printing machines, sterilization equipment, etc. are also conceivable. Also conceivable are devices from packaging technology and palletizing technology. The individual devices 111 - 114 can be connected to one another by means of conveying devices for the containers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com