Marine high-pressure-resistant bidirectional rotary sealing ring

A bidirectional rotation and sealing ring technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as waste, and achieve the effects of reducing waste, saving costs, and reducing related expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

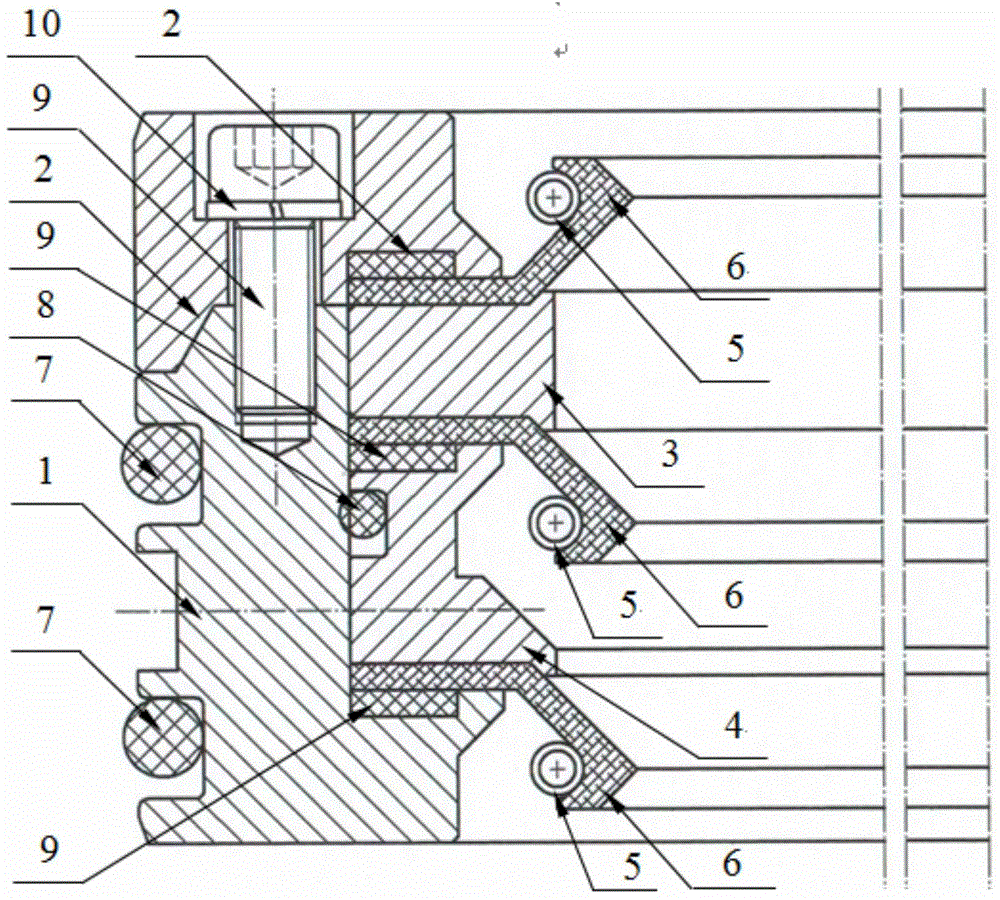

[0020] A marine high-pressure resistant two-way rotary seal ring, which is a combined seal ring, that is, the seal ring is made of metal casing 1, end cover 2, first support ring 3, second support ring 4 and PTFE turning with spring 5 Formed sealing lip 6 and other auxiliary sealing first O-ring 7, second O-ring 8, rectangular sealing ring 9, first fastener 10, second fastener 11, in which the spring 5 is installed On the sealing lip 6 formed by PTFE turning, the first O-ring 7 is installed on the metal shell 1, the second O-ring 8 is installed on the second support ring 4, and then the sealing lip 6, the first support ring 3. The second support ring 4 and the rectangular sealing ring 9 are figure 2 After the metal shell 1 is sequentially installed in the metal shell 1, the end cover 2 is connected and fastened to the metal shell 1 by using the first fastener 10 and the second fastener 11 .

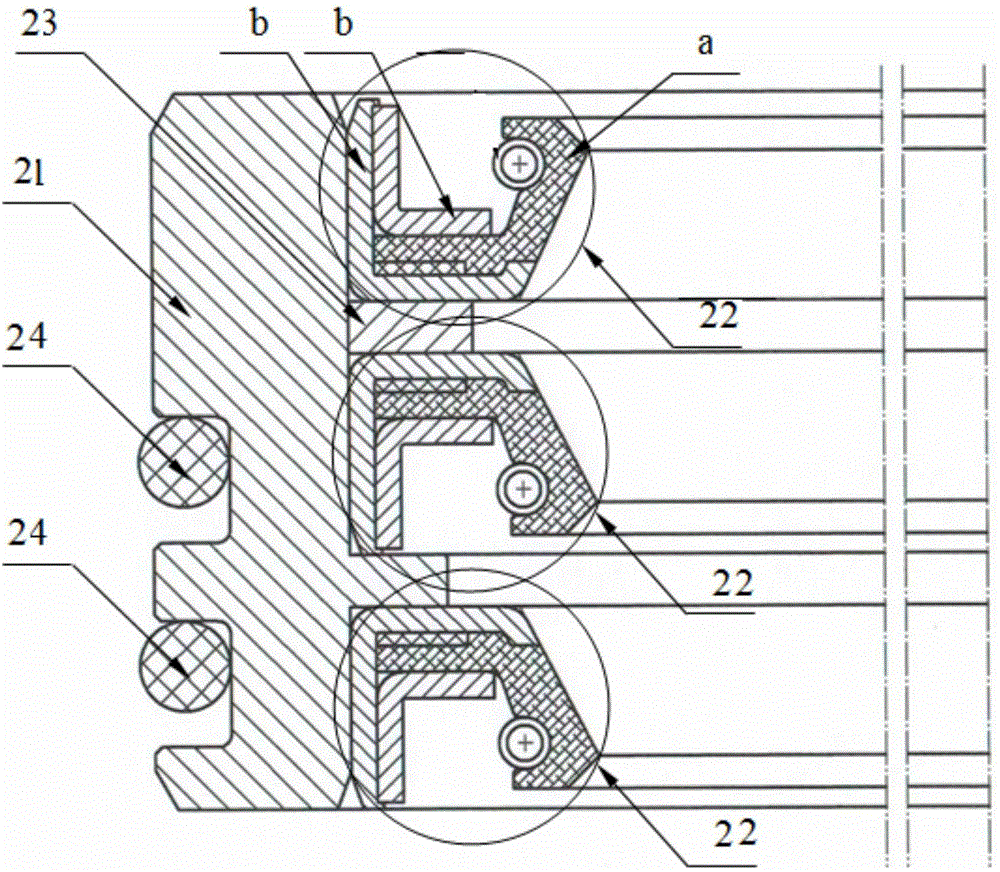

[0021] figure 2 The three PTFE sealing lips 6 formed by turning are divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com