Needle bar equipped with vibration absorber

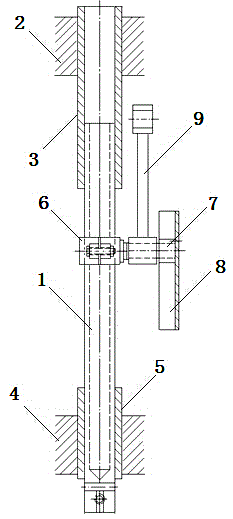

A vibration absorber and needle bar technology, which is applied to sewing equipment, needle holders for sewing machines, textiles and papermaking, etc., can solve problems such as sewing machine failures and increased wear of moving rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

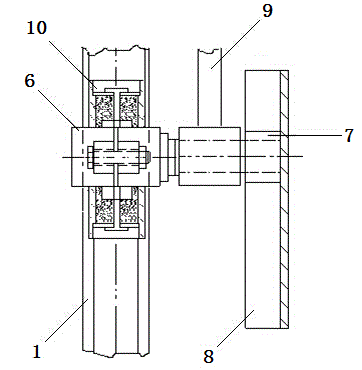

[0033] see figure 2 As shown, the vibration absorber is a built-in vibration absorber 10 , which is placed in the inner cavity of the cylinder of the needle bar 1 , and its height is located on the axis line of the slider pin 6 . The cheap vibration of needle bar 1 is bending vibration, drives needle bar 1 to move through connecting rod 9, slide block pin 6, and the axis line of slide block pin 6 is that needle bar 1 bends the most at the place near.

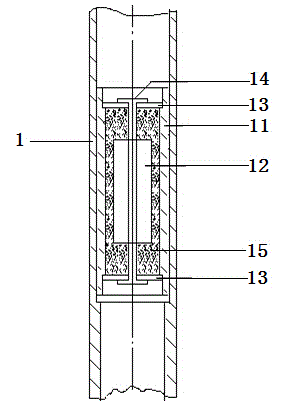

[0034] Further, see image 3 As shown, the built-in vibration absorber 10 includes a vibration absorber tube body 11, a cylindrical mass 12 is arranged inside the vibration absorber tube body 11, and a circular spacer is provided at the upper and lower ends of the vibration absorber tube body 11. Pad 13, the cylindrical mass 12 is fixed between the upper and lower circular spacers 13 by copper leaf springs 14, the inner wall of the vibration absorber tube body 11 and the upper and lower circular spacers The shaped spa...

Embodiment 2

[0038] see Figure 5 As shown, the shock absorber is an external shock absorber 17, which is tightly sleeved on the outer wall of the cylinder of the needle bar 1 and installed on the mounting pad 23 on the outer wall of the cylinder of the needle bar 1. The needle bar 1 The outer diameter of the cylinder is 8 mm, the height of the external vibration absorber 17 is located below the slider pin 6, and the upper plane of the external vibration absorber 17 is 5 mm away from the axis line of the slider pin 6. -10mm.

[0039] Further, the external vibration absorber 17 includes a vibration absorber outer tube 18 and a vibration absorber inner tube 19, an annular mass 20 is arranged between the vibration absorber outer tube 18 and the vibration absorber inner tube 19, the An annular spacer 21 is arranged on the upper and lower ends of the outer tube 18 of the vibration absorber and the inner tube 19 of the vibration absorber, and the annular mass 20 is fixed on the upper and lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com