Flow equalizing hot blast heater with premix air flow nozzle interconnection and air supply flow curved flowing

A technology of air flow nozzles and hot blast stoves, which is applied in the field of uniform flow hot blast stoves, and can solve the problems of low combustion intensity, low mixing rate of gas and air, and low combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

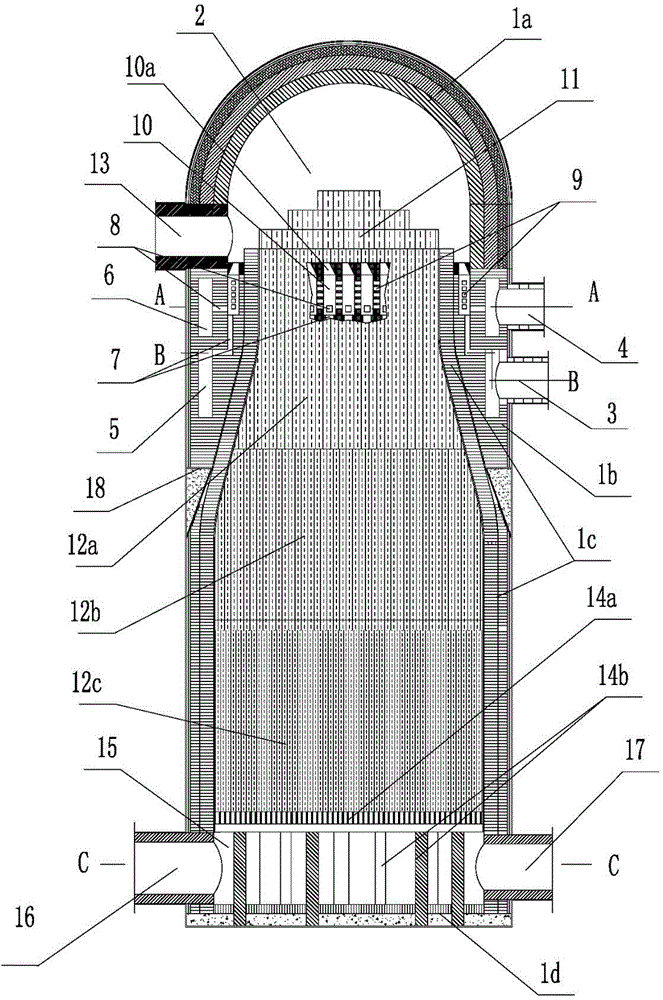

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

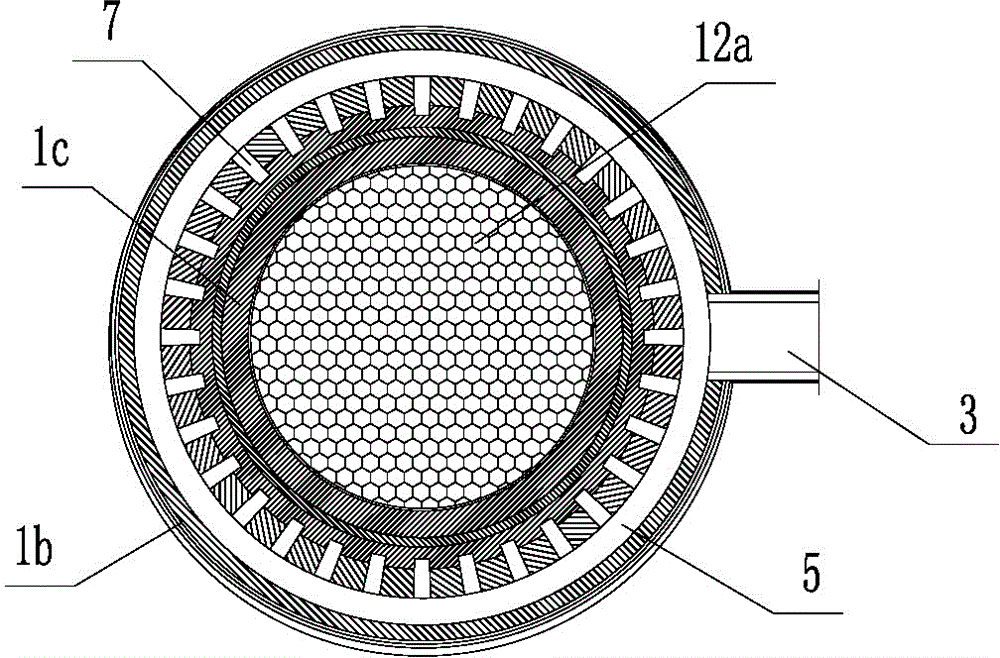

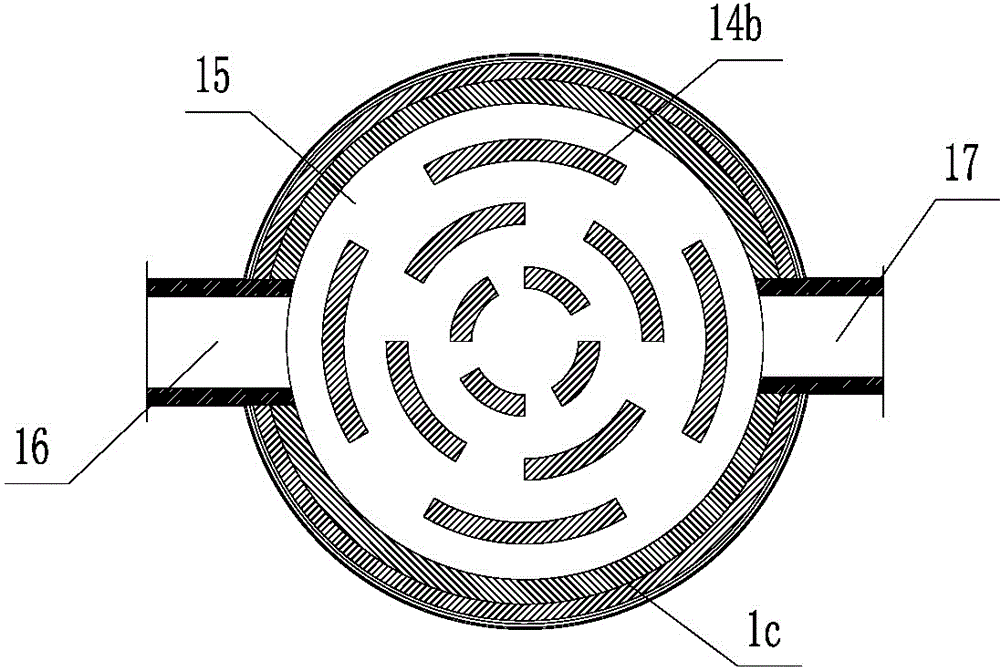

[0011] Such as Figure 1-Figure 4 As shown, the present invention includes a combustion chamber wall 1a, a combustion chamber 2, a hot blast outlet pipe 13, a burner wall 1b, a gas intake pipe 4, an air intake pipe 3, a gas distribution ring 6, an air distribution ring 5, and a gas distribution ring 5. The main nozzle 8, the air main nozzle 7, the airflow premixing nozzle channel 10 and the premixed airflow regulating nozzle 10a on it, the combustion chamber wall 1a is a hemispherical dome at the top and a cylinder at the bottom of the hemispherical dome. Connection structure, the combustion chamber wall 1a is coaxially connected with the lower cylindrical burner wall 1b, the lower end of the burner wall 1b is supported on the outer wall of the regenerator wall 1c through the support ring 18, and the combustion chamber wall Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com