Soybean epoxy compound hydrolase preparation and immobilization method

An epoxy compound and immobilization method technology, applied in the field of materials, can solve the problems of long immobilization time and low enzyme loading, and achieve the effects of improving the recovery rate of enzyme activity, increasing the enzyme loading, and improving the immobilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

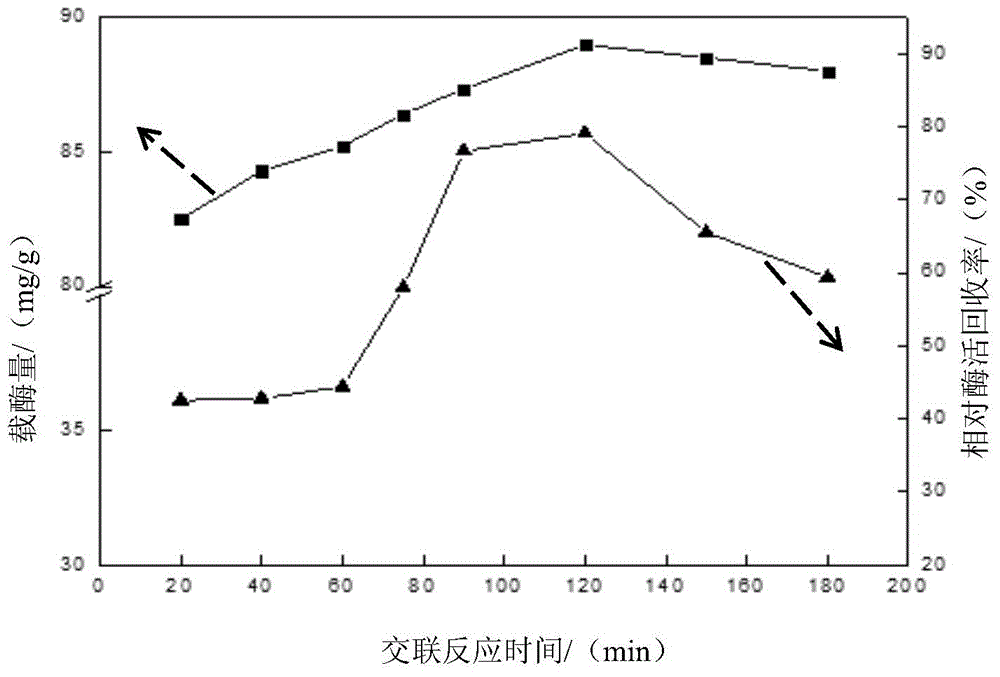

[0032] Soybean epoxide hydrolase is dispersed in a phosphate buffer solution with a pH of 6.5 to configure an enzyme solution; 50mg UiO-66-NH 2 Mix nanocrystals (substrate) with 1mL 5mg / mL enzyme solution (mass ratio 10:1); add a certain volume of saturated ammonium sulfate solution (saturation is 100%) under stirring at 0°C to make the final saturation of ammonium sulfate The concentration is 80%, stirred at a stirring speed of 200rpm for 30min; a certain amount of 25% glutaraldehyde solution is added to make the final mass of glutaraldehyde 65mg, and the cross-linking reaction is stirred at 0°C and 300rpm for 120min; washed and freeze-dried to obtain Soybean epoxide hydrolase preparation 1.

[0033] The relative enzyme activity recovery rate of enzyme preparation 1 was 82.911%. The soybean epoxide hydrolase and UiO-66-NH in the product 2 The substrate ratio was 89.56 mg / g. Carry out the test of enzyme activity to enzyme preparation 1, test result is as follows Figure 4 ,...

Embodiment 2

[0036] Soybean epoxide hydrolase is dispersed in a phosphate buffer solution with a pH of 6.5 to configure an enzyme solution; 50mg UiO-66-NH 2 Mix with 1mL 5mg / mL enzyme solution (mass ratio 10:1); add a certain volume of saturated ammonium sulfate solution under stirring at 0°C to make the final saturation of ammonium sulfate 80%, stir at 200rpm for 30min; add A certain amount of 25% glutaraldehyde solution was used so that the final mass of glutaraldehyde was 65 mg, and the cross-linking reaction was stirred at 0° C. and 300 rpm for 20 minutes; washed and freeze-dried to obtain soybean epoxy compound hydrolase preparation 7.

[0037] The relative enzyme activity recovery rate of enzyme preparation 7 was 42.676%. The soybean epoxide hydrolase and UiO-66-NH in the product 2 The base material ratio is 82.49mg / g.

[0038]Only change the cross-linking reaction time, other conditions are identical with embodiment 2, obtain following enzyme preparation respectively: cross-linking...

Embodiment 3

[0040] Soybean epoxy compound hydrolase is dispersed in a phosphate buffer solution with a pH of 6.5 to configure an enzyme solution; 25mg UiO-66-NH 2 Mix the nanocrystals (i.e. substrate) with 1mL of 5mg / mL enzyme solution (mass ratio 5:1); add a certain volume of saturated ammonium sulfate solution under stirring at 0°C, so that the final saturation of ammonium sulfate is 80%. Stir at a speed of 200 rpm for 30 min; add a certain amount of 25% glutaraldehyde solution to make the final mass of glutaraldehyde 65 mg, stir at 0°C and 300 rpm for 120 min; wash and freeze-dry to obtain soybean epoxy compound hydrolase preparation 14.

[0041] The relative enzyme activity recovery rate of enzyme preparation 14 was 64.191%. The soybean epoxide hydrolase and UiO-66-NH in the product 2 The substrate ratio was 173.58 mg / g.

[0042] Change only UiO-66-NH 2 The mass ratio of nanocrystal (being substrate) and enzyme, other conditions are identical with embodiment 3, obtain following enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com