A kind of container bottom plate and preparation method thereof

A technology of container floor and bottom layer, applied in chemical instruments and methods, packaging, manufacturing tools, etc., can solve the problems of high cost, low processing efficiency, and low utilization rate of bamboo container floor of bamboo container, and achieve strong designability and ease of use. The effect of cleaning and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

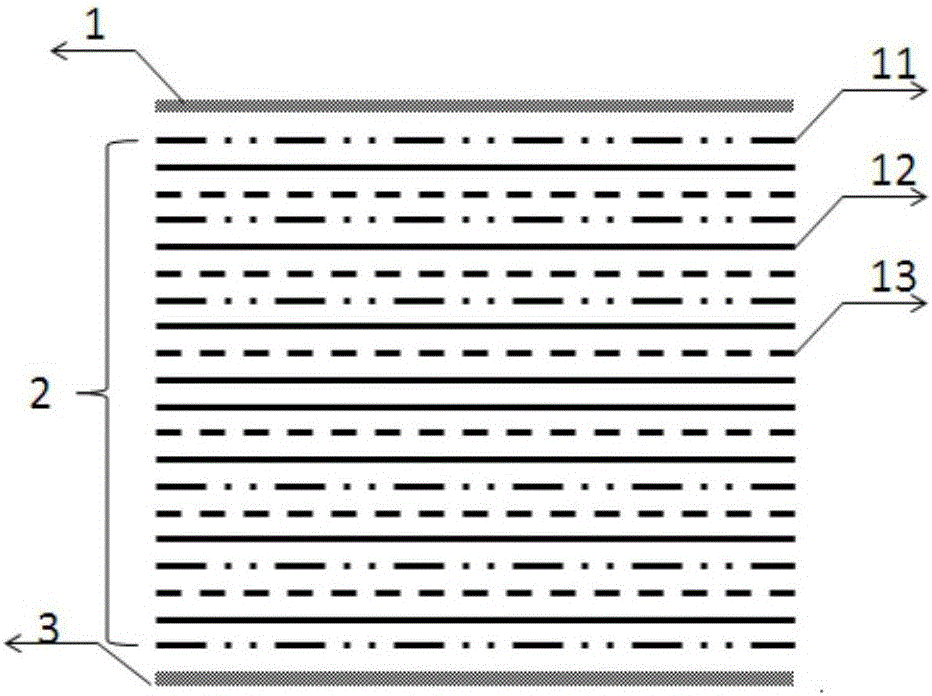

[0049] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the bottom plate of the container shown in Embodiment 1.

[0050] The bottom plate of the container is made by the following methods:

[0051] (1) Spread the continuous glass fiber, compound it with the extruded and melted polypropylene resin matrix, and then roll to obtain a fiber-reinforced thermoplastic prepreg tape. The mass percentage of the fiber in the prepreg tape is 40%, and the thickness of the single layer 0.50mm, take 4 layers and lay them up alternately at 0-90 degrees, and then heat-press the fiber-reinforced thermoplastic prepreg tape and a layer of PET non-woven fabric into a sheet at a temperature of 180°C and a pressure of 4MPa. The hot pressing time is 20 minutes, and then the cold pressing is performed for 30 minutes to obtain the fiber-reinforced thermoplastic sheet, that is, the surface layer 1 and the bottom layer 3;

[0052] (2) Moso bamboo is cut to form strip-shaped ...

Embodiment 2

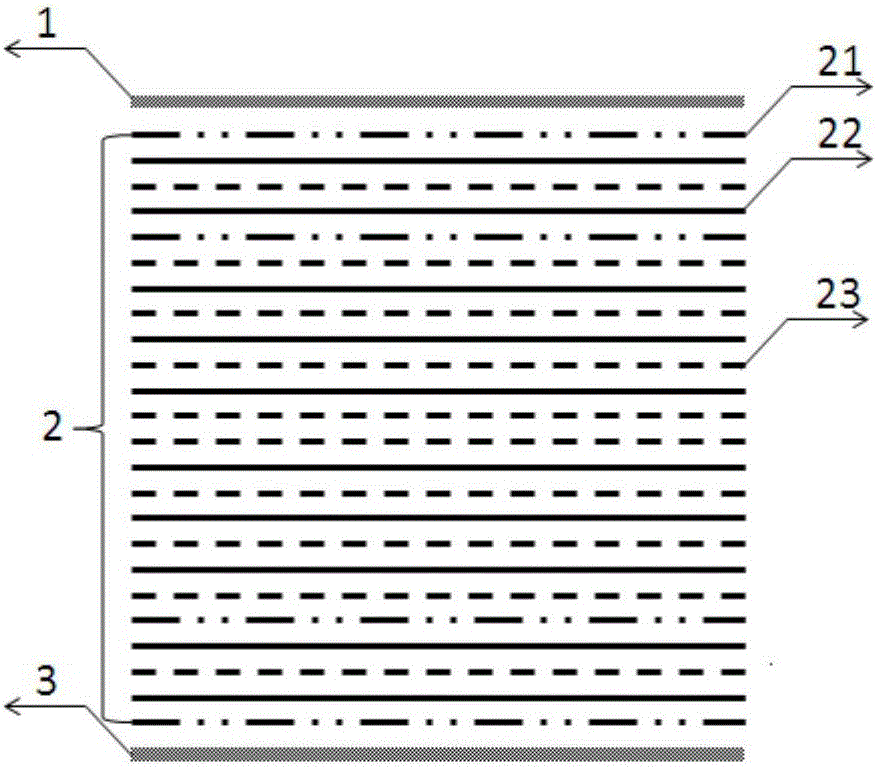

[0058] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of the bottom plate of the container shown in Embodiment 2.

[0059] (1) Spread the continuous glass fiber, compound it with the extruded and melted polypropylene resin matrix, and then roll to obtain a fiber-reinforced thermoplastic prepreg tape. The mass percentage of the fiber in the prepreg tape is 45%, and then Under the condition of 175°C and pressure of 2MPa, the thickness of a single layer is 0.33mm, take 3 layers and lay them up alternately at 0-90 degrees, and heat-press the fiber-reinforced thermoplastic prepreg tape and a layer of PET non-woven fabric into a sheet, The hot pressing time is 25 minutes, and then the cold pressing is performed for 35 minutes to obtain fiber-reinforced thermoplastic sheets, that is, the surface layer 1 and the bottom layer 3;

[0060] (2) the bamboo is cut to form strip-shaped bamboo strips; the bamboo strips are arranged in parallel in one direction, a...

Embodiment 3

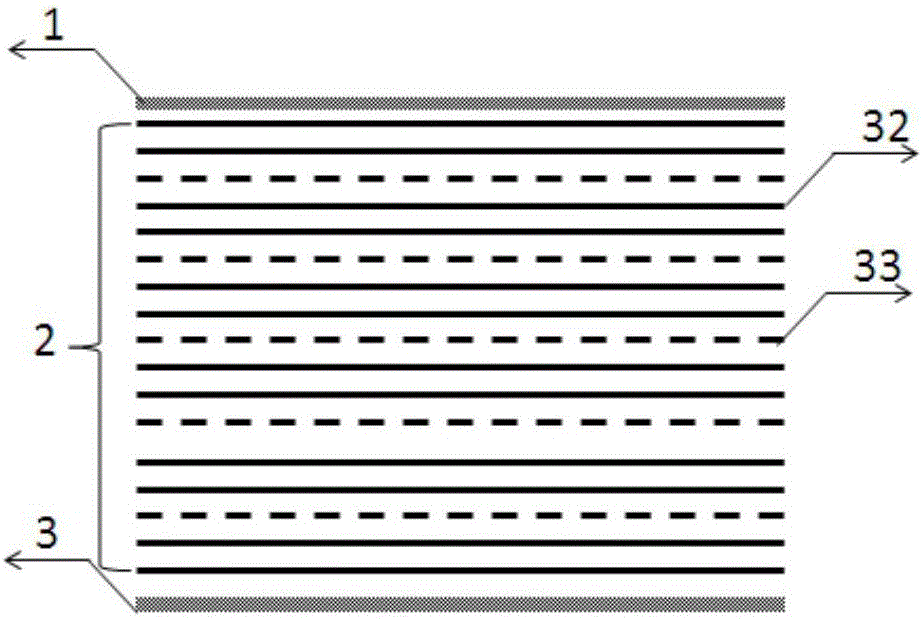

[0066] Such as image 3 as shown, image 3 It is a structural schematic diagram of the bottom plate of the container shown in Embodiment 3.

[0067] (1) Spread the continuous glass fiber, compound it with the extruded and melted polypropylene resin matrix, and then roll to obtain a fiber-reinforced thermoplastic prepreg tape. The mass percentage of the fiber in the prepreg tape is 50%, and the thickness of the single layer 0.50mm, take 4 layers and lay them up alternately according to 0 / 90 degrees, and then heat-press the fiber-reinforced thermoplastic prepreg tape and a layer of PET non-woven fabric into a sheet at a temperature of 170°C and a pressure of 3MPa. The hot pressing time is 30 minutes, and then the cold pressing is performed for 40 minutes to obtain fiber reinforced thermoplastic sheets, that is, the surface layer 1 and the bottom layer 3;

[0068] (2) Moso bamboo is cut to form strip-shaped bamboo strips; the bamboo strips are unidirectionally arranged in paral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com