Round tube chamfering machine

A technology of chamfering machine and chamfering mechanism, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of reducing production cost, high procurement cost, unfavorable enterprises, etc., and achieves reduced production cost, low cost, good structure The effect of design science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

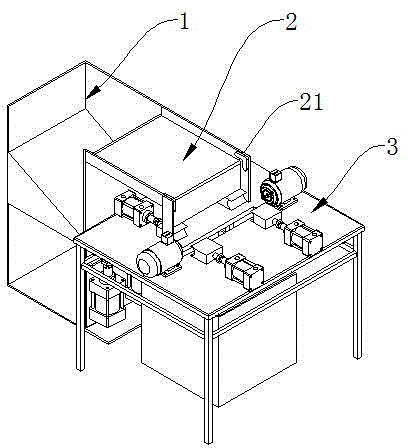

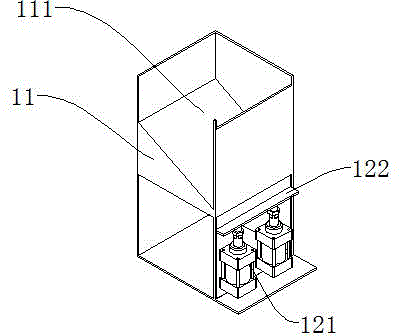

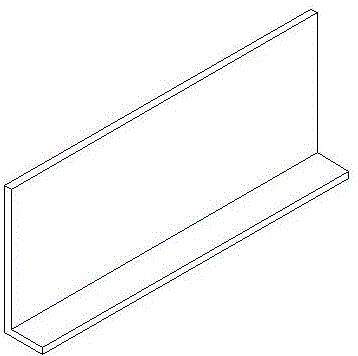

[0019] refer to Figure 1 to Figure 5 , a round pipe chamfering machine, comprising a round pipe storage mechanism 1, a transmission device 2 and a chamfering mechanism 3, the round pipe storage mechanism includes a round pipe storage device 11 and a round pipe pushing device, the round pipe The storage device includes a storage space, and the storage space is provided with a slope 111, and the slope is provided with a pushing groove; the circular tube pushing device includes two pushing cylinders 121 and is connected to the front ends of the two pushing cylinders. The circular tube pushing plate 122; the chamfering mechanism includes a workbench 31, on which there are 4 cylinder clamping devices distributed in a matrix, chamfering devices symmetrically distributed on both sides of the cylinder clamping device And the discharge trough 34 that is positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com