Rice crust comprising Lentinus edodes and soybean and preparation method of rice crust

A technology for shiitake mushrooms and soybeans is applied in the field of shiitake mushroom and soybean rice noodles and their preparation, which can solve the problems of single variety in nature, and achieve the effects of simple and environmentally friendly preparation process, improved taste, and convenient eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

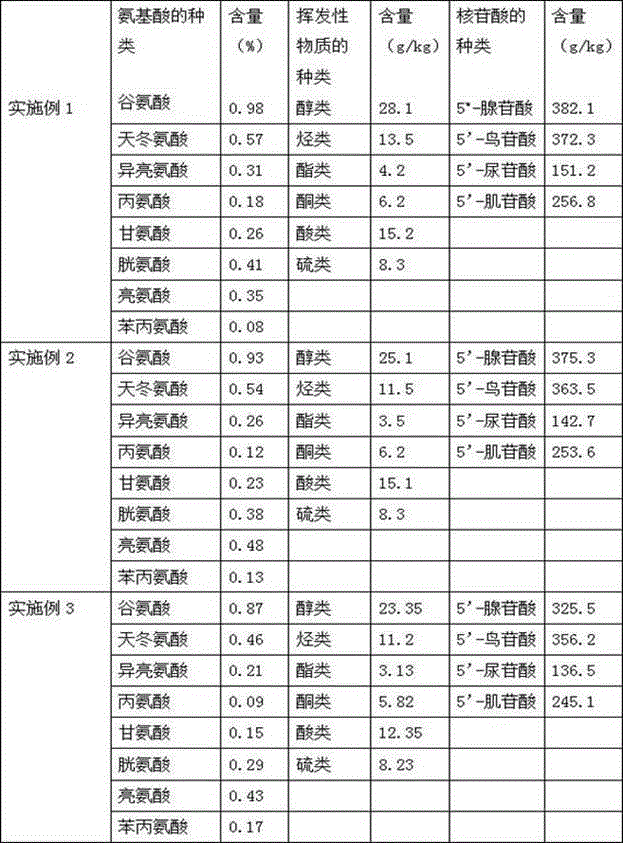

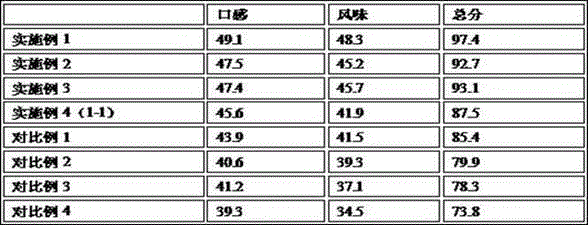

Embodiment 1

[0033] (1) Weigh 800g of soybeans and crush them to obtain soybean powder for later use. Weigh 700 g of dried shiitake mushrooms, wash them, and soak them in warm water. Cut the soaked shiitake mushrooms into pieces, measure 700 mL of water and put them into a pulper together with the cut shiitake mushrooms to make a pulp to obtain shiitake mushroom pulp. The enzymatic hydrolysis of shiitake mushroom slurry was carried out by step-by-step enzymatic hydrolysis to obtain shiitake mushroom enzymatic hydrolysis solution; the first step, cellulase, the amount of enzyme added was 250,000 U / g soaked shiitake mushrooms, the enzymatic hydrolysis temperature was 55°C, and the time was 120 minutes; Step 2, compound protease, 1.5 million U / g soaked shiitake mushrooms, enzymolysis temperature 55°C, time 150min; compound protease is composed of neutral protease and trypsin according to the enzyme activity ratio of 2:1; the third step, 5, -Phosphodiesterase, the amount of enzyme added is 55...

Embodiment 2

[0035] Take by weighing 800g of soybean, pulverize to obtain soybean powder for subsequent use. Weigh 700 g of dried shiitake mushrooms, wash them, and soak them in warm water. Cut the soaked shiitake mushrooms into pieces, measure 700 mL of water and put them into a pulper together with the cut shiitake mushrooms to make a pulp to obtain shiitake mushroom pulp. Use compound protease to enzymatically hydrolyze the shiitake mushroom slurry for 150min under the temperature condition of 55°C to obtain the shiitake mushroom enzymatic hydrolysis liquid; g soaked shiitake mushrooms. Weigh 1500g of flour, mix it with soybean powder and shiitake mushroom enzymatic solution to make dough, and shape into slices. Fry the slices in a vacuum fryer. The vacuum frying conditions are: temperature 95°C, vacuum degree 0.090Mpa, time 8min; deoiling conditions are: vacuum degree 0.090Mpa, deoiling speed 400r / min, time 8min. Sprinkle with seasonings, let cool, pack and seal to get the finished ...

Embodiment 3

[0037] Take by weighing 800g of soybean, pulverize to obtain soybean powder for subsequent use. Weigh 700 g of dried shiitake mushrooms, wash them, and soak them in warm water. Cut the soaked shiitake mushrooms into pieces, measure 700 mL of water and put them into a pulper together with the cut shiitake mushrooms to make a pulp to obtain shiitake mushroom pulp. Use neutral protease to enzymatically hydrolyze the shiitake mushroom pulp at 55°C for 150 minutes to obtain the shiitake mushroom enzymatic hydrolysis solution; the amount of neutral protease is 1.5 million U / g soaked shiitake mushrooms. Weigh 1500g of flour, mix it with soybean powder and shiitake mushroom enzymatic solution to make dough, and shape into slices. Fry the slices in a vacuum fryer. The vacuum frying conditions are: temperature 95°C, vacuum degree 0.090Mpa, time 8min; deoiling conditions are: vacuum degree 0.090Mpa, deoiling speed 400r / min, time 8min. Sprinkle with seasonings, let cool, pack and seal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com