Testing machine for testing variable load reducer for washing machines

A technology for speed reducers and washing machines, which is applied in the testing of machine gears/transmission mechanisms, etc. It can solve problems such as poor stability of loading performance, lower measurement accuracy of angle encoders, and large size, so as to achieve stable loading performance, improve testing efficiency, and high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

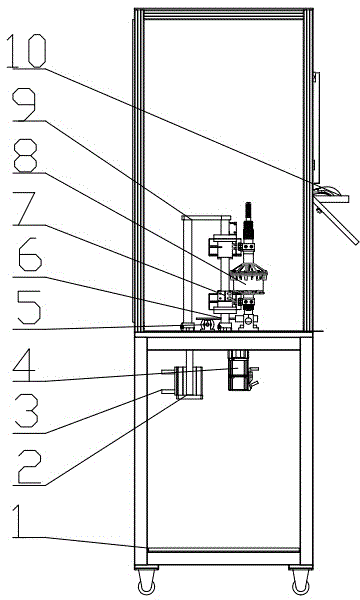

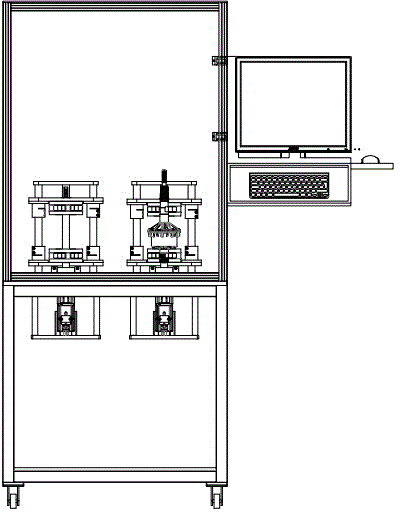

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] see Figure 1~Figure 2 , a variable load washing machine speed reducer testing machine in this embodiment consists of two sets of independent stations. Each station contains a servo motor 4, the servo motor 4 is connected to the tested reducer 8 through a shaft sleeve, and the tested reducer 8 is clamped by an adjustable fixture 7, and the adjustable fixture 7 is positioned by a guide rail 9 ; The pneumatic cylinder 2 is connected to the shaft sleeve through the connecting line 6, and the tested reducer 8 is loaded, the connecting line 6 is supported by the pulley 5, and the air pipe 3 is installed on the pneumatic cylinder 2; the guide rail 9 and the pulley 5 are directly installed on the machine base 1, the servo motor 4 and the pneumatic cylinder 2 are fixed on the base 1 through ribs.

[0014] The servo motor 4 has its own torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com