A method for controlling the spraying operation of an emulsion-type deicing agent spraying vehicle

A control method and snow-melting agent technology, applied in the direction of electric speed/acceleration control, cleaning method, construction, etc., to achieve the effect of convenient movement, uniform spraying and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

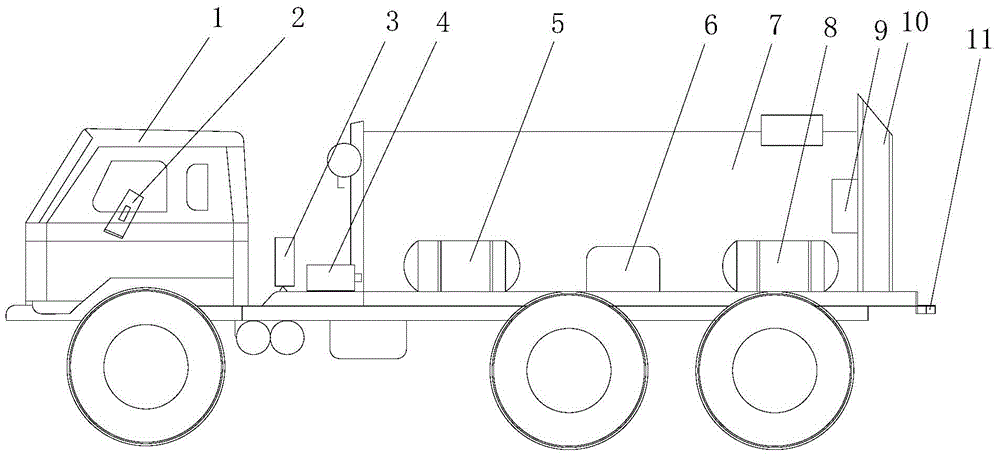

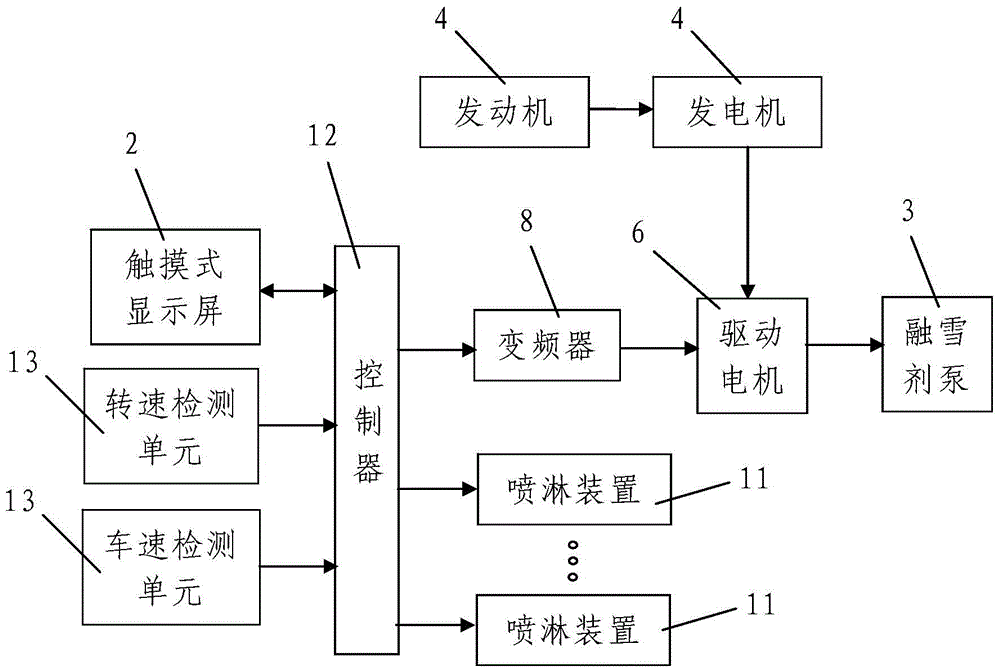

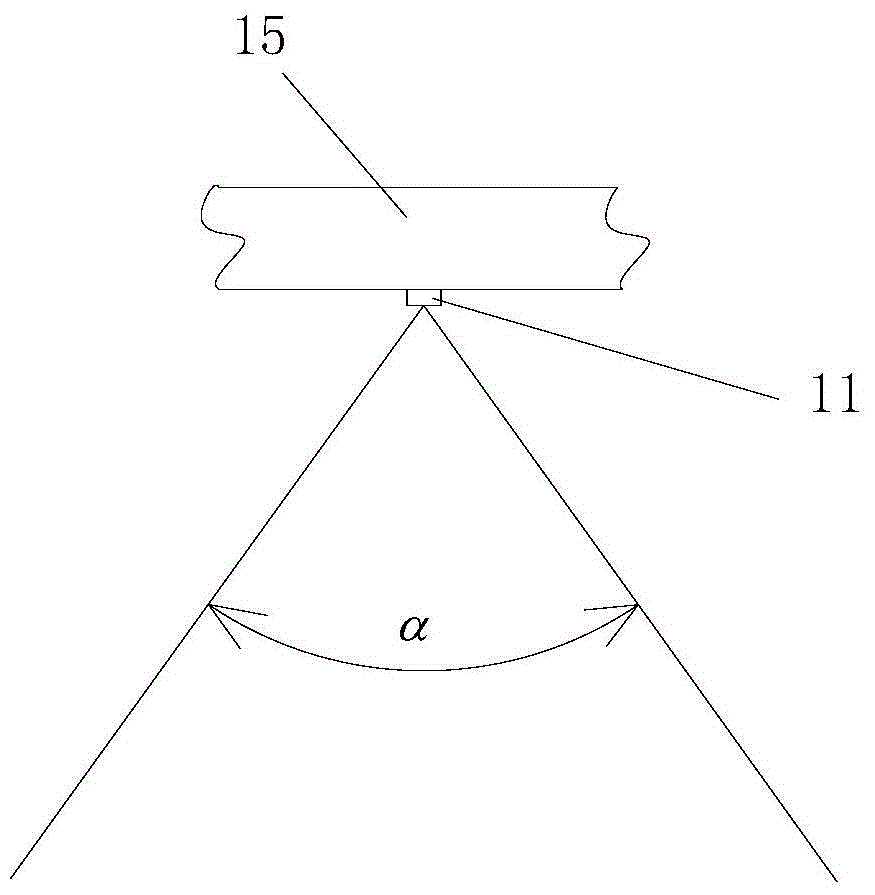

[0050] like figure 1 , figure 2 Shown a kind of emulsion type deicing agent sprinkler vehicle, comprises carrying vehicle 1, is installed on carrying vehicle 1 and the deicing agent storage tank 7 that deicing agent is housed inside and sprays the adorned deicing agent in the deicing storage tank 7 to The spraying system on the road, the spraying system is installed on the carrying vehicle 1. Described spraying system comprises a plurality of spraying devices 11 that are all installed in the rear portion of carrying vehicle 1, is connected to the delivery pipeline between the liquid outlet of deicing agent storage tank 7 and a plurality of described spraying devices 11, deicing deicing agent The deicing agent contained in the storage tank 7 is pumped to a plurality of deicing agent pumps 3 of the spraying devices 11 and an AC frequency conversion speed regulation system for controlling the pumping speed of the deicing agent pump 3, and the deicing agent pump 3 is a quantitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com