High temperature-resistant micro-expansive caulking mud and preparation method thereof

A micro-expansion, high-temperature-resistant technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of secondary pollution, high cost of blasting clay, and non-expansion of blasting clay, so as to reduce the blast furnace Production cost, improvement of secondary pollution, and the effect of promoting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

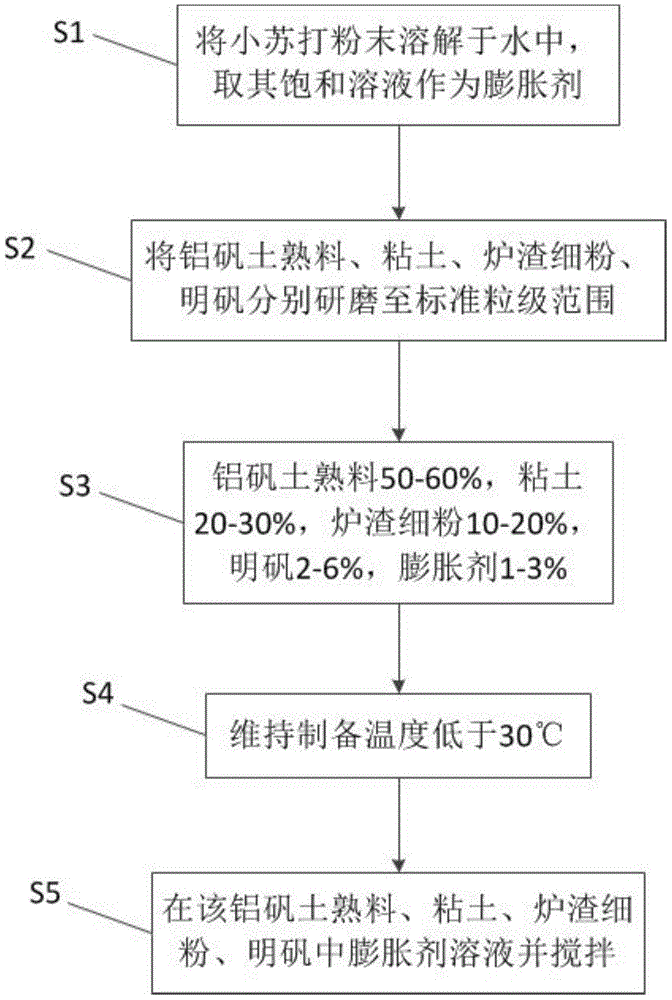

[0026] The above-mentioned high-temperature-resistant micro-expansion caulking mud has high strength, can avoid secondary pollution, is not easy to fall off, and has low cost. Such as figure 1 Shown, the preparation method of high temperature resistant micro-expansion caulking mud of the present invention comprises 5 main steps:

[0027] S1: Dissolve baking soda powder in water, take its saturated solution as swelling agent.

[0028] S2: Grinding the bauxite clinker, clay, slag fine powder and alum to the standard size range respectively.

[0029] S3: Bauxite clinker 50-60%, clay 20-30%, slag fine powder 10-20%, alum 2-6%, expansion agent 1-3%.

[0030] S4: maintaining the preparation temperature below 30°C.

[0031] S5: Add an expansion agent solution to the bauxite clinker, clay, slag fine powder, and alum and stir.

[0032] The details of the five steps are described below.

[0033] (1) The principle of micro-expansion: NaHCO in the expansion agent 3 Chemical reaction...

Embodiment 1

[0051] The first group A: Bauxite 56%, clay 26%, slag fine powder 15%, alum 2%, expansion agent 1%.

[0052] (1) Dissolve baking soda powder into pure water at 20-30°C, with a weight ratio of 1.5:10, stir for 5-10 minutes to obtain a saturated solution, and let stand for more than 15 minutes.

[0053] (2) After crushing bauxite, clay, slag fine powder and alum, grind them to the particle size range required in Table 3.

[0054] (3) According to the weight ratio of each raw material in the first group A in Table 4, weigh and put it into the stirring equipment, and the stirring time is 5-10 minutes.

[0055] (4) Weigh 1% expansion agent and stir for 10-15 minutes.

[0056] (5) Packed into bags, it is a finished product.

[0057] (6) Repeat steps (3)-(5) according to the proportion of the second group B and the third group C.

[0058] (7) After baking the caulking mud to 200°C for 2 hours, test its physical properties:

[0059] project

Embodiment 2

[0061] The second group B: bauxite 55%, clay 24%, slag fine powder 15%, alum 4%, expansion agent 2%.

[0062] (1) Dissolve baking soda powder into pure water at 20-30°C, with a weight ratio of 1.5:10, stir for 5-10 minutes to obtain a saturated solution, and let stand for more than 15 minutes.

[0063] (2) After crushing bauxite, clay, slag fine powder and alum, grind them to the particle size range required in Table 3.

[0064] (3) According to the weight ratio of each raw material in the first group A in Table 4, weigh and put it into the stirring equipment, and the stirring time is 5-10 minutes.

[0065] (4) Weigh 1% expansion agent and stir for 10-15 minutes.

[0066] (5) Packed into bags, it is a finished product.

[0067] (6) Repeat steps (3)-(5) according to the proportion of the second group B and the third group C.

[0068] (7) After baking the caulking mud to 200°C for 2 hours, test its physical properties:

[0069] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com