A method and special equipment for enhancing the mixing effect of sludge and chemicals

A technology of mixing effect and special equipment, applied in chemical instruments and methods, mixers, dehydration/drying/thickened sludge treatment, etc., can solve the problem of unstable performance of sludge particle flocs, inability to achieve dehydration rate, and increased energy consumption and other problems, to achieve the effect of improving dehydration efficiency, simple and easy operation, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

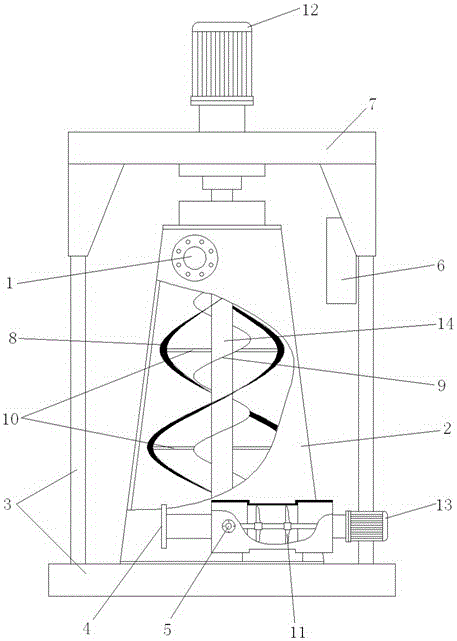

[0020] The sludge granulation equipment of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation examples:

[0021] Such as figure 2 The special equipment shown as a method for strengthening the mixing effect of sludge and chemicals is a kind of sludge granulation equipment, involving a stirring mechanism. The stirring mechanism includes a slow stirring mechanism and a fast stirring mechanism. The fast stirring mechanism is mounted on the frame 3 and the slow stirring mechanism, and the fast stirring mechanism is connected to the sludge inlet 4 and the flocculant inlet 5; the slow stirring mechanism is mainly composed of a conical shell 2 with internal equidistant helix 9 and outer unequal conical helix 8 , the inner equidistant helix and the outer unequal conical helix are coaxially installed on the stirring shaft 14, the outer unequal conical helix and the stirring shaft are installed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com