High efficiency and low energy consumption hemp biological degumming solid-liquid mixed ventilation fermenter

A technology of aeration fermentation and low energy consumption, applied in the field of hemp fiber textiles, can solve the problems of difficulty in spinning high-count yarns, high production costs, high consumption of raw materials and energy consumption, etc., and shorten the time required for heating and cooling. , High-efficiency gas-liquid mixing effect, the effect of improving the gas-liquid mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

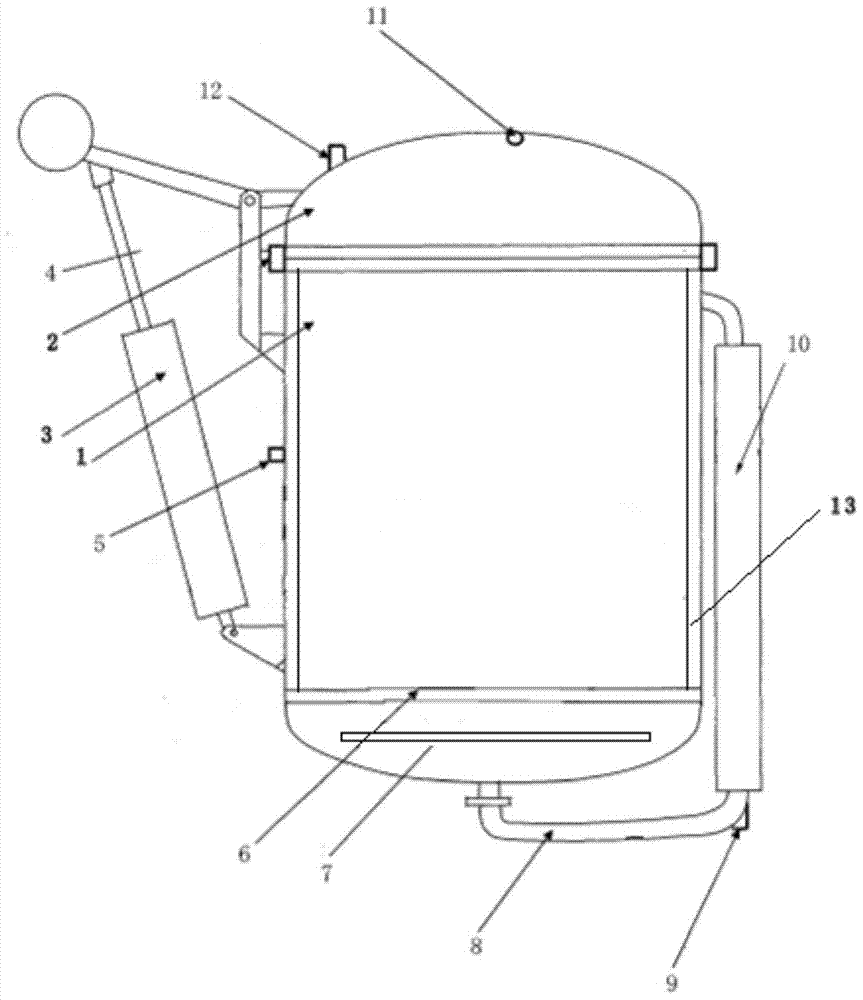

[0040] as the picture shows,

[0041] High-efficiency and low-energy-consumption hemp biological degumming solid-liquid mixed aerated fermenter, including a tank body 1, a tank cover 2 arranged on the tank body 1, an outer circulation pipe 8 and an opening and closing tank arranged on the tank body 1 The tank cover opening and closing device of the cover 2, the side wall of the tank body 1 is provided with a tank side wall interlayer heat exchange device 13, the bottom of the tank body 1 is provided with a sieve plate 6, and the bottom of the sieve plate 6 is provided with a serpentine heat exchange tube 7, the outer circulation pipe 8 includes a horizontally arranged bottom horizontal pipe, a top horizontal pipe and a vertically arranged riser pipe, one end of the bottom horizontal pipe communicates with the bottom of the tank body 1, and the other end of the bottom horizontal pipe communicates with the bottom end of the riser pipe , the top of the riser pipe communicates wit...

Embodiment 2

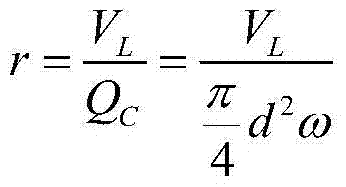

[0068] According to the filling capacity of hemp cage, the tank volume of the present invention's design is 10 tons, and the inner diameter of outer circulation pipe 8 is 220mm, and nozzle 9 diameters are 10.5mm.

[0069] The fermenter designed in this way can achieve a cycle period of 2.5-3.5 minutes when the tank inlet pressure into the nozzle is 0.1Mpa. Others are consistent with Example 1.

Embodiment 3

[0071] Carry out following degumming process according to the device in embodiment 2:

[0072] Ramie biological degumming

[0073] The alkalophilic bacillus (the strain is preserved in the China Center for Type Culture Collection (CCTCC), No. CCTCC M96009) was activated by culturing in liquid locust bean gum medium at 37°C for 24-48 hours. Among them: liquid locust bean gum medium composition (g / l): locust bean gum: 2 (g / l); yeast extract: 2 (g / l); K 2 HPO 4 : 1 (g / l); MgSO 4 ·7H 2 O: 0.1 (g / l); peptone: 10 (g / l); pH 10, sterilized at 121°C for 15 minutes.

[0074] Then transfer in the medium that contains ramie, the medium composition that contains ramie is: ramie: 650kg; (NH 4 ) 2 SO 4 : 1.5% (according to the quality of ramie); K 2 HPO 4 : 0.5% (according to ramie quality); Bath ratio 10~12; Use Na 2 CO 4 Regulate pH10; Wherein, the substratum that contains ramie is placed in the device of embodiment 2 (tank volume is 10 tons, and the inner diameter of outer circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com