A treatment system for high-salt waste water

A treatment system and high-salt technology, which is applied in the field of high-efficiency separation, concentration and crystallization of salt in industrial high-salt wastewater. and other problems, to achieve the effect of compact structure, small footprint and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Taking an industrial high-salt wastewater as the research object, the high-efficiency separation and concentration experiments of sodium chloride and sodium sulfate in the wastewater were carried out. Firstly, the water quality of highly saline wastewater is detected as COD≤60mg / L, TDS≤9000mg / L, NaCl≤3000mg / L, NaCl 2 SO 4 ≤6000mg / L, total hardness ≤2600mg / L.

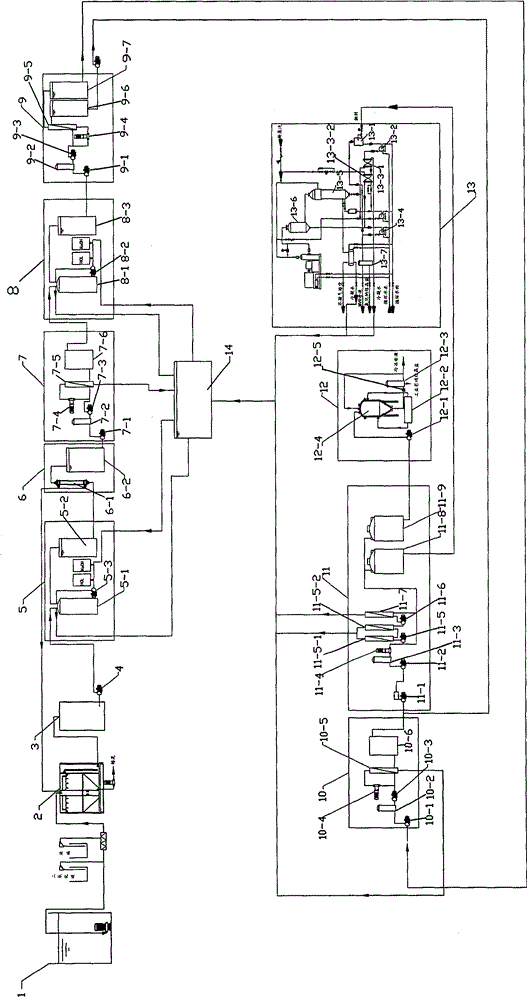

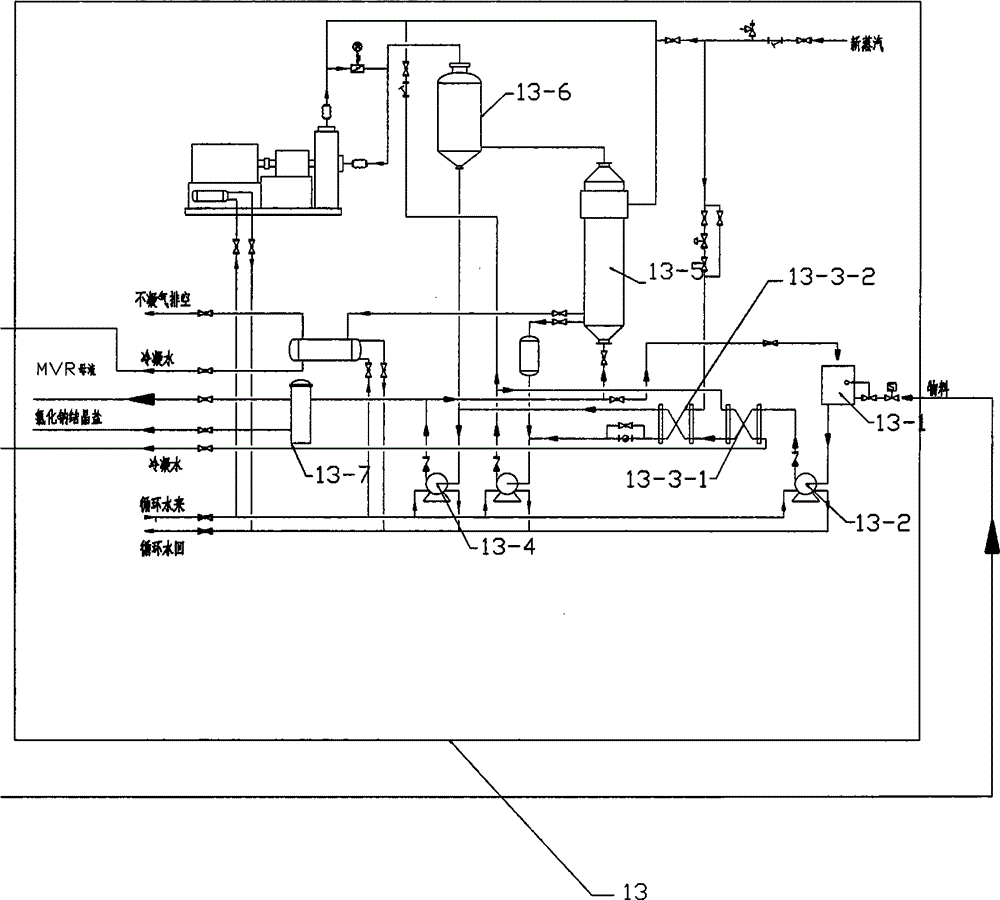

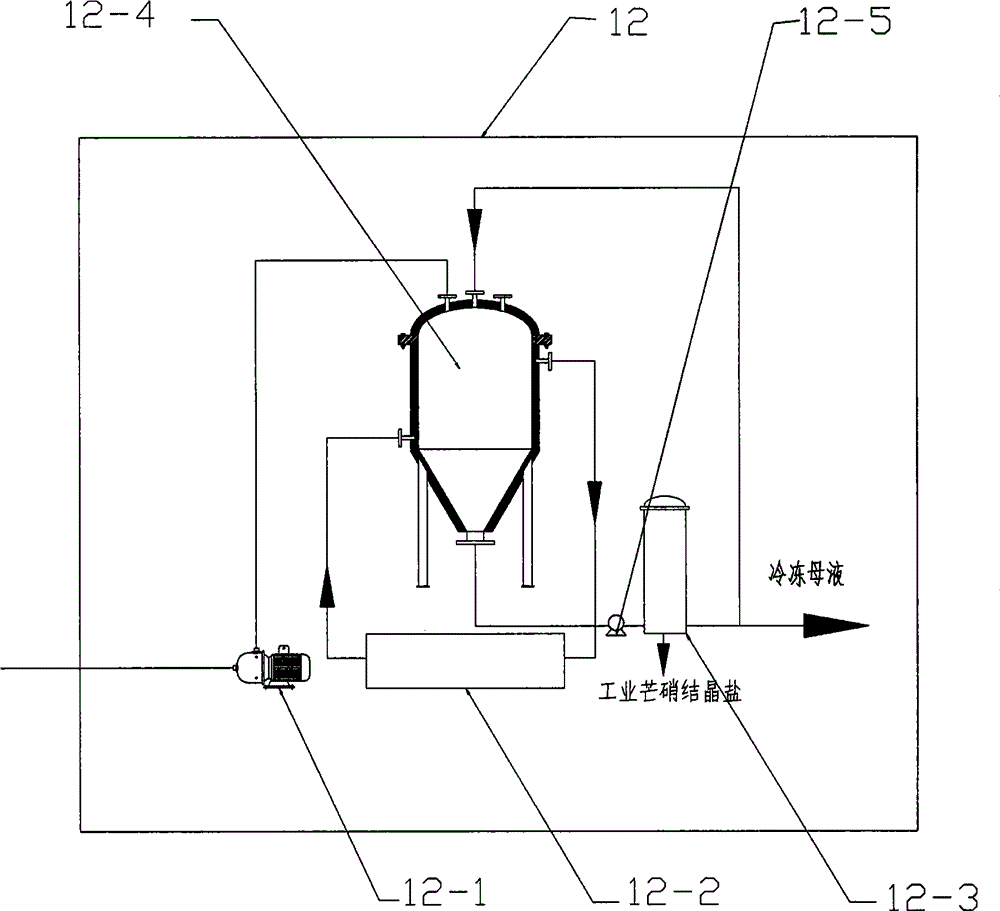

[0027] Such as figure 1Shown, the present invention comprises following treatment unit: adjusting tank 1, total water production tank 14, high-density sedimentation tank 3, V-shaped filter tank 4, first section ion exchange resin system 5, ultrafiltration system 6, first section reverse osmosis System 7, second-stage ion exchange resin system 8, high-pressure nanofiltration system 9, second-stage reverse osmosis system 10, high-pressure flat membrane system 11, MVR evaporation crystallization system 13 and frozen crystallization system 12, among which, the high The salty wastewater is connected to the high-salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com