Multifunctional lifting cargo container for motor vehicle

A multi-functional, motor-vehicle technology, applied to motor vehicles, vehicles used for freight, and load fixing, can solve problems such as heightening and widening loading, waste of packaging resources, and mismatching, so as to reduce the damage rate of goods and facilitate Mechanical binding, the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

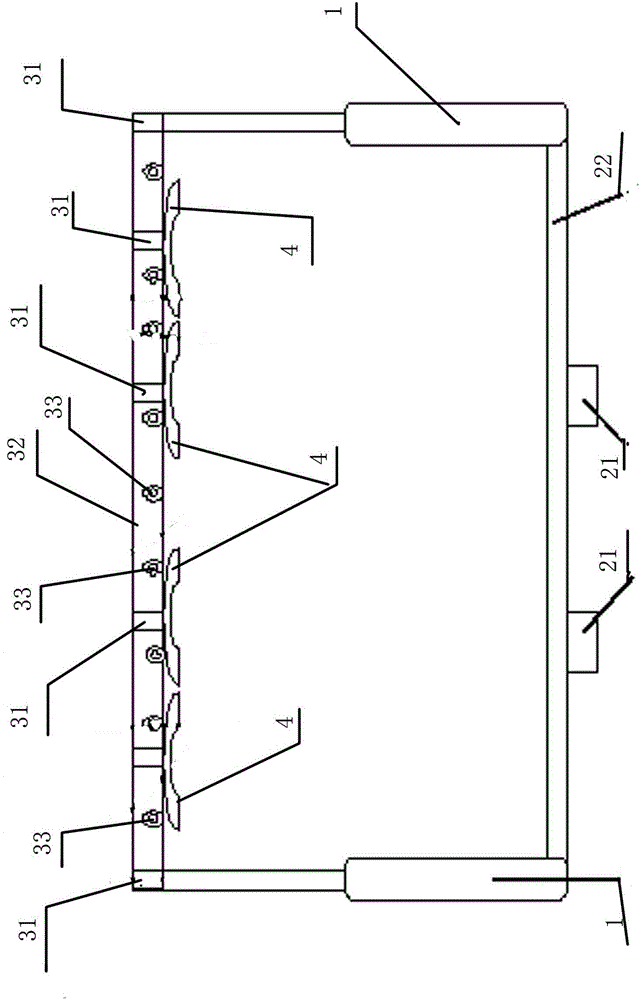

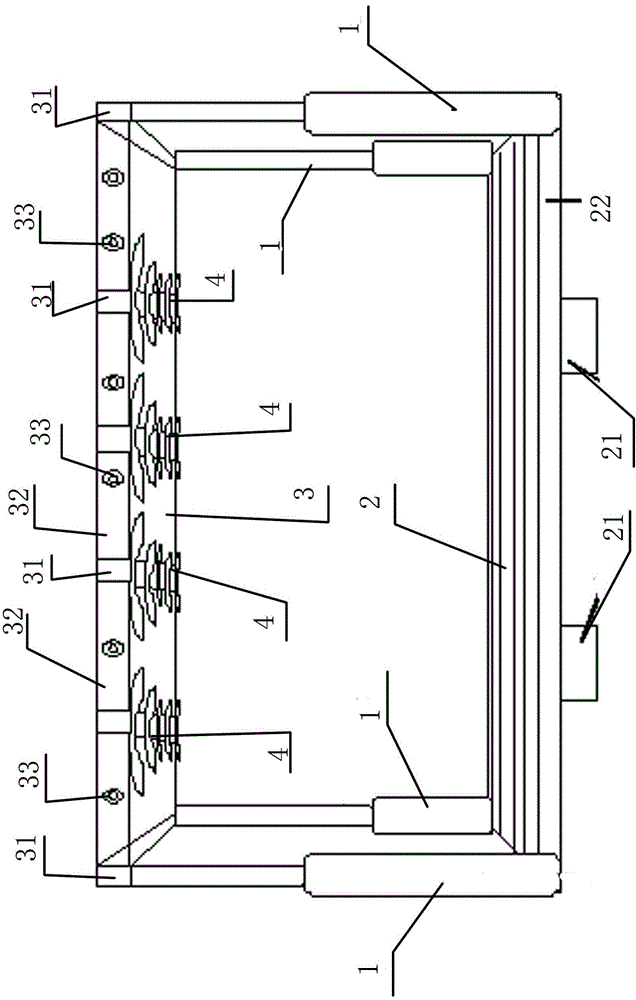

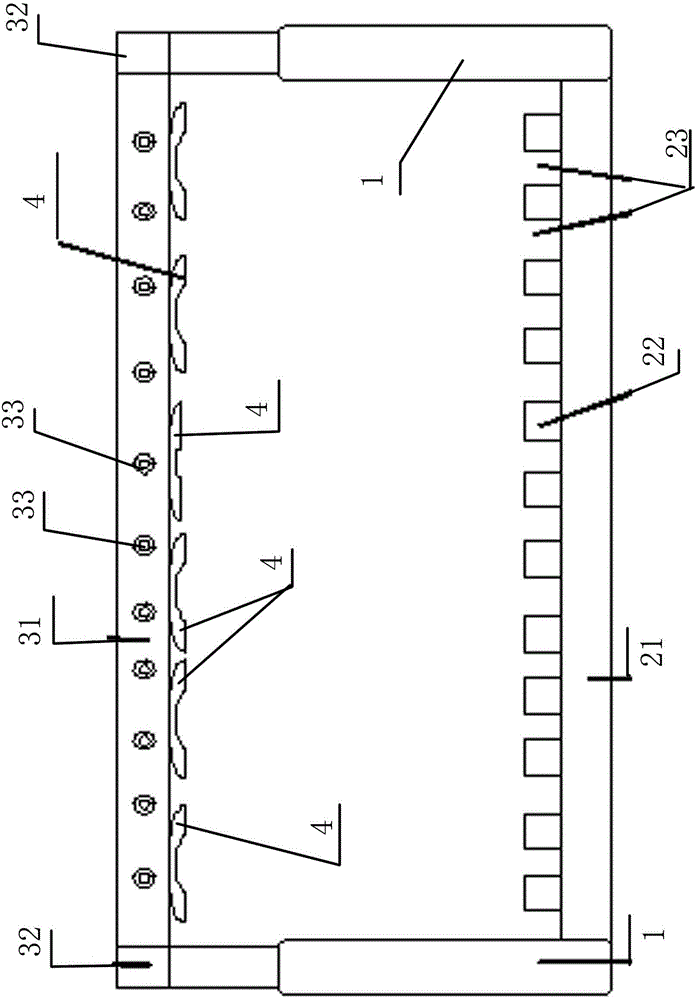

[0040] Embodiment 1 (motor vehicle container is long 3.35 meters, sees Figure 1 to Figure 10 )

[0041] The lifter 1 of the multi-function lifting container of the motor vehicle of the present invention preferably can lift four telescopic hydraulic oil cylinders of 3 meters, and one end of the four telescopic hydraulic oil cylinders is respectively set up and fixed to be placed on the bottom 2 of the container with multiple grooves 23 planes. four terminal angles, the other ends of the four telescopic hydraulic cylinders are respectively fixedly connected to the four terminal angles at the lower end of the container top 3; To raise or lower, the four telescopic hydraulic cylinders can not only be directly used as a column supporting the top 3 of the cargo box, but also can be used as a lifter 1 and a hoist; figure 2 .

[0042] The cargo box bottom 2 of the multi-function lifting cargo box of the motor vehicle in this embodiment adopts fourteen cargo box bottom support be...

Embodiment 2

[0048] Example 2 : the structure of the top 3 of the motor vehicle multifunctional lifting cargo box of the present invention can also be used separately , Such as carry out technological transformation to existing motor vehicle cargo box, respectively install a lifter 1 and a cargo box top 3 at the four terminal angle positions of the motor vehicle cargo box bottom, constitute a cargo box that the motor vehicle top can lift, and effect is When the top 3 is lowered to the surface of the goods, the arc-shaped spring clips are pressed against the goods by the gravity of the top of the container, and the two ends of the arc are respectively clamped on uneven goods; during transportation, even if the goods are loose, the arc-shaped spring clips will The overall weight of the clip through the top of the cargo box can also naturally compress the cargo.

Embodiment 3

[0049] Example 3: The structure of the bottom 2 of the motor vehicle multi-functional lifting container of the present invention can also be used alone , Carry out technological transformation to existing motor vehicle cargo box, be made into by several grooves 23 side by side at the bottom of motor vehicle cargo box and form the cargo box bottom 2 that has many grooves 23 planes, wherein the height of each groove 23 is 4- 30cm, the width is 4-30cm, the length is 40-300cm, and the distance between two adjacent grooves 23 is 3-60cm. The effect of such a structure is that the goods on the multi-fork of the forklift are placed on the bottom of the motor vehicle cargo box 2 The groove plane of the forklift, the multi-fork of the forklift synchronously falls into the groove 23, and the multi-fork of the forklift extends the groove and exits to complete the mechanical loading; or the multi-fork of the forklift is inserted into the bottom groove 23 of the container, and the goods in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com