Tension optimizing and compensating method for adjusting rolling force

A tension optimization and rolling force technology, applied in the direction of rolling force/roll gap control, tension/pressure control, etc., can solve the problems of surface quality reduction, out-of-tolerance strip shape, and increased rolling force, and achieve improved The effect of strip rolling product quality, great economic benefit, and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

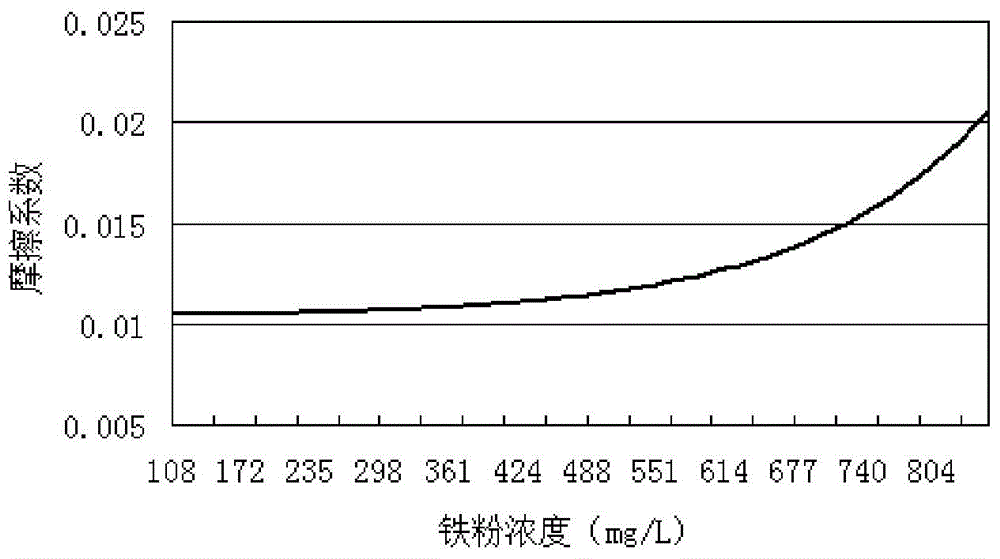

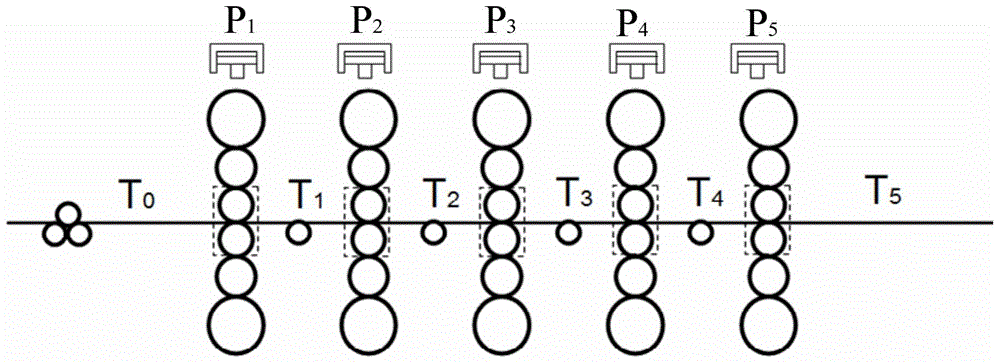

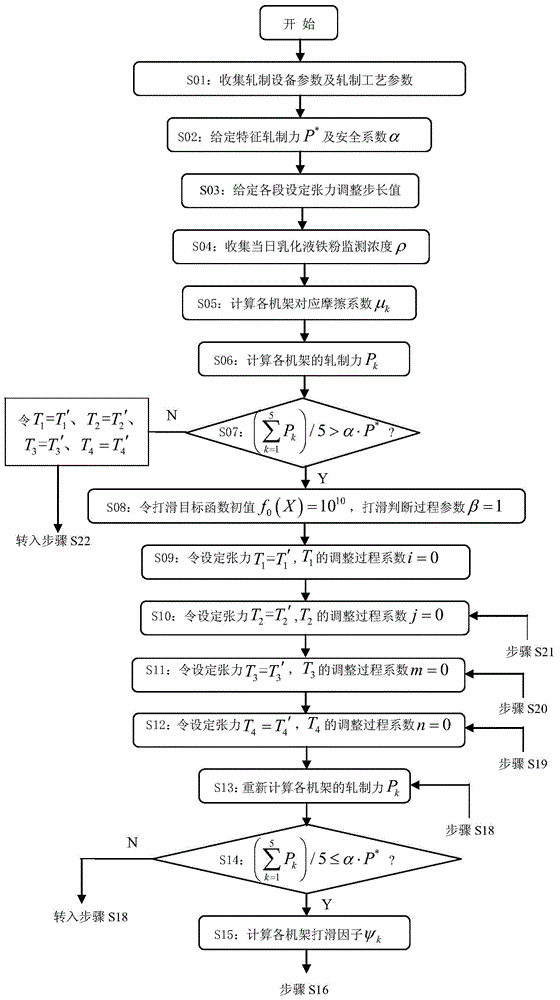

[0049] image 3 with Figure 4 Is an embodiment of the tension optimization compensation method for rolling force adjustment of the present invention. image 3 with Figure 4 In the control flow chart shown, the tension optimization compensation method of the present invention includes the following steps:

[0050] S01: Collect all equipment and rolling process parameters in the current rolling process, including the diameter D of the work roll of each stand 1 =513mm, D 2 =486.5mm, D 3 =532mm, D 4 =532.5mm, D 5 =493.3mm; actual reduction rate ε 1 =24.64748%, ε 2 =37.26682%, ε 3 =31.95121%, ε 4 =32.04431%, ε 5 =24.91337%; actual tension:

[0051] T 0 ′=132.57kN,

[0052] T 1 ′=255, 64kN,

[0053] T 2 ′=156.84kN,

[0054] T 3 ′=105.24kN,

[0055] T 4 ′=75.6kN,

[0056] T 5 ′=29.55kN;

[0057] Maximum tension allowed by the unit T max =300kN, and the incoming strip thickness h 0 =2.82mm, width B=955mm, exit thickness h 5 =0.455mm, steel grade is SPHC; see figure 2 .

[0058] S02: Given ch...

Embodiment 2

[0102] S01: Collect all equipment and rolling process parameters in the current rolling process, including the diameter D of the work roll of each stand 1 =514.4mm, D 2 =488.1mm, D 3 =535.2mm, D 4 =525mm, D 5 =509.8mm; actual reduction rate ε 1 =32.74609%, ε 2 =40.12407%, ε 3 =38.78635%, ε 4 =36.42558%, ε 5 =32.1913%; actual tension:

[0103] T 0 ′=74.06001kN,

[0104] T 1 ′=122.8kN,

[0105] T 2 ′=80.2N,

[0106] T 3 ′=49.76kN,

[0107] T 4 ′=37.6kN,

[0108] T 5 ′=12.05kN;

[0109] Maximum tension allowed by the unit T max =300kN, and the incoming strip thickness h 0 =1.82mm, width B=839mm, exit thickness h 5 =0.19mm, steel type is MRT4CA;

[0110] S02: Given characteristic rolling force P * =6569.932kN, safety factor α=1.2;

[0111] S03: Set tension adjustment step value ΔT for each segment s = T s ' / N, in this embodiment, the total number of tension adjustment steps N=20,

[0112] ΔT 1 =T 1 / 20=6.14kN,

[0113] ΔT 2 =T 2 / 20=4.01kN,

[0114] ΔT 3 =T 3 / 20=2.488kN,

[0115] ΔT 4 =T 4 / 20=1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com