Method for preparing panaxoside and panaxynol through enzymatic zymotechnics

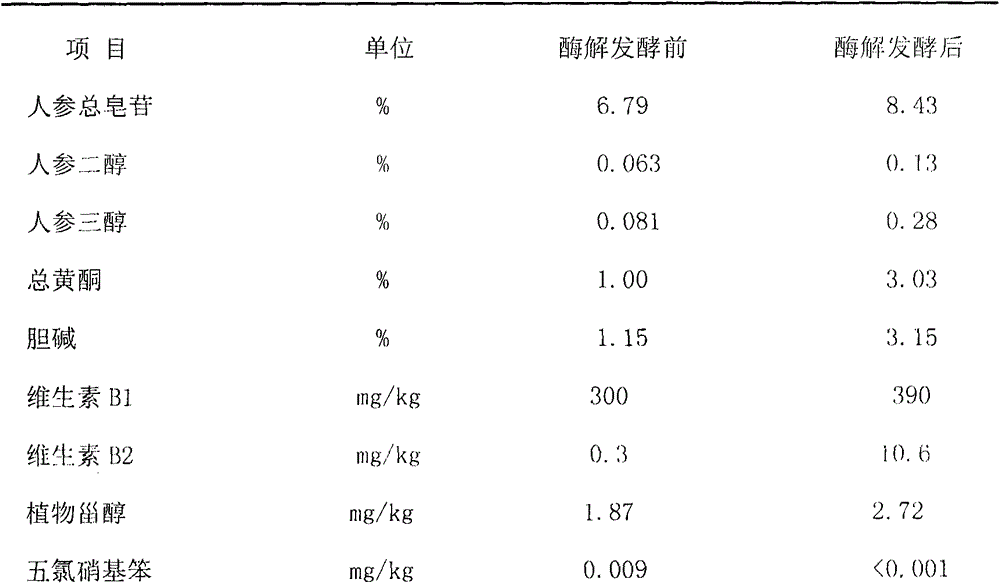

A technology of ginsenoside and fermentation method, which is applied in the field of enzyme engineering, can solve the problems that residues cannot be recycled, pesticide residues cannot be decomposed, and the extraction rate of active ingredients is low, so as to improve the content and small molecule characteristics, improve physiological activity, and eliminate pesticides. Residue reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

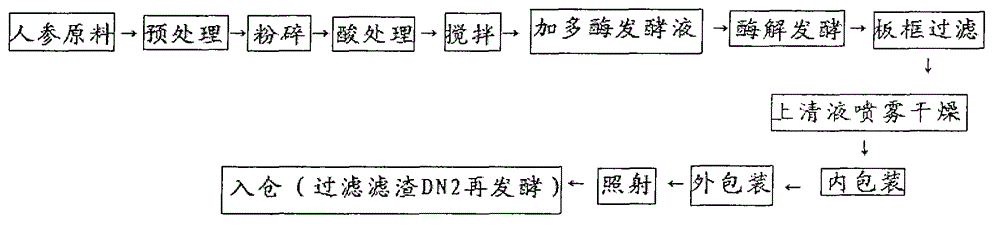

[0025] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing ginsenosides and ginsenosides by an enzymatic fermentation method, including the following steps:

[0026] S1. After washing the Changbai Mountain ginseng, dry it at 50℃~60℃, and crush it to 40 mesh fineness;

[0027] S2. Add the mineral water based on the principle of grasping the raw material powder on the hand and disperse it immediately, soak in lactic acid for 18 hours, and adjust the PH value between 4.5 and 6.5;

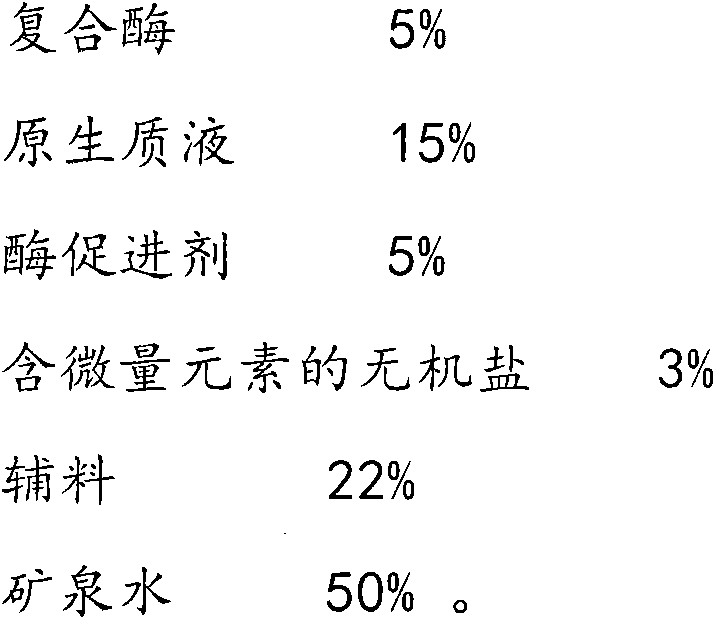

[0028] S3. Place the mixture obtained in step S2 in an enzymatic fermentation tank, add the enzymatic fermentation broth fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com