Coal economizer equipment for afterheat recovery and application method thereof

A technology of waste heat recovery and economizer, applied in lighting and heating equipment, waste heat treatment, treatment of discharged materials, etc., can solve the problems of temperature fluctuation of added water, affecting the quality of sintering mixture, treatment of excess hot water, etc. Stable and beneficial to the effect of stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

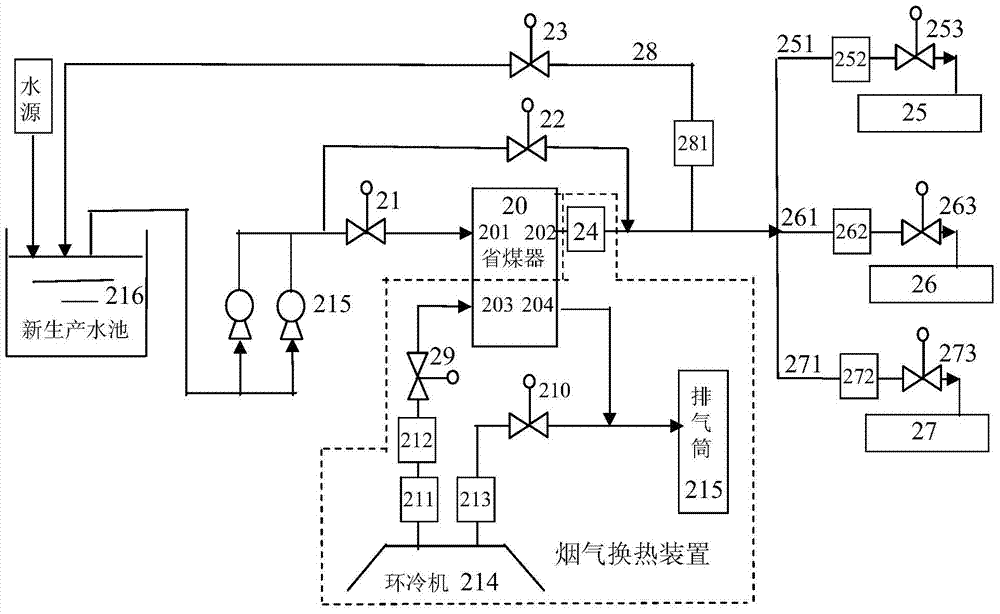

[0065] Economizer equipment for waste heat recovery of the present invention see figure 2 , the economizer 20 has a cold water inlet 201, a hot water outlet 202, a hot flue gas inlet 203, and a cold flue gas outlet 204, and the economizer equipment includes industrial Water heating device and flue gas heat exchange device, in which:

[0066] Described industrial water heating device sees figure 2 The part outside the middle dotted box, which includes:

[0067] Two water pumps 215, one of which is in use and the other is standby, the input ends of the two are connected on the same cold water input pipe, the output ends of the two are connected on the same cold water output pipe, and the cold water output pipe is passed through the water inlet motor The valve 21 is connected to the cold water inlet 201 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com