Spraying device baffle plate for forming metalized film screen zone

A technology of metallized film and spraying device, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of screen distribution and screen edge blurring and blackening, and achieve clear screen and stable capacity. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings.

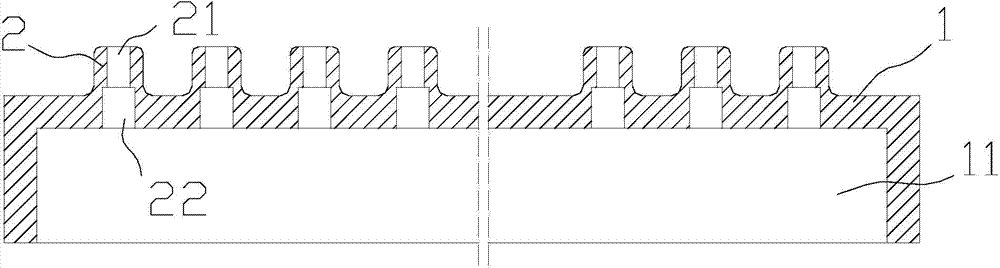

[0016] The present invention is arranged at the outlet of the spraying device for spraying shielding oil vapor on the surface of the film, see figure 1 , 2 shown. The inner side of the baffle 1 is provided with an air storage cavity 11 for storing shielding oil vapor. The baffle 1 is provided with nozzles 2 distributed along the length direction for spraying shielding oil on the surface of the film. Hole 21, the top of the air storage chamber 11 is provided with a sub-air storage chamber 22 with enlarged cross-section at the inlet end of the fuel injection hole 21 of each nozzle 2 for buffering the pressure, and the depth of the sub-air storage chamber 22 is 0.1-0.15 cm. The sub-air storage chamber 22 may be a cylinder, an elliptical cylinder or a cone, or may be a stepped shape with a diameter gradually decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com