Integrated high-performance sewage treatment apparatus

A kind of sewage treatment equipment, high-efficiency technology, applied in aerobic and anaerobic process treatment and other directions, can solve the problem that non-professionals are difficult to operate sewage treatment plants, the influent water volume and concentration change greatly, and the sewage treatment buildings are complex, etc. problems, to achieve the effect of low requirements for operators, reduced sludge treatment costs, and good denitrification and phosphorus removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

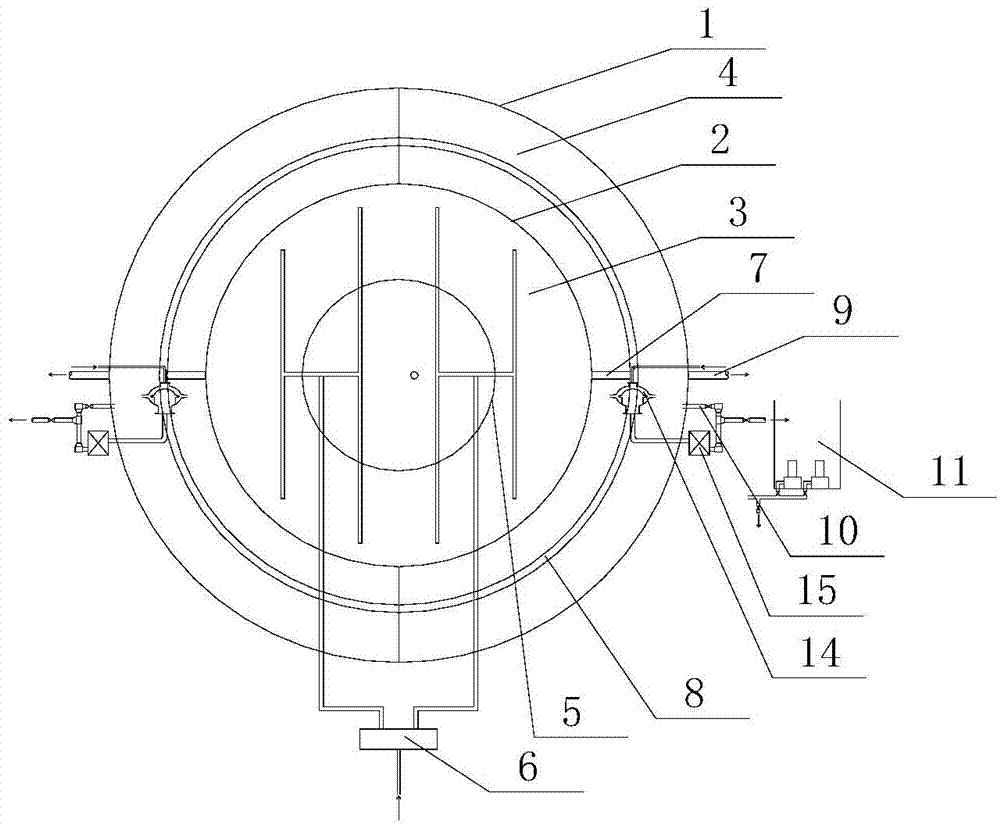

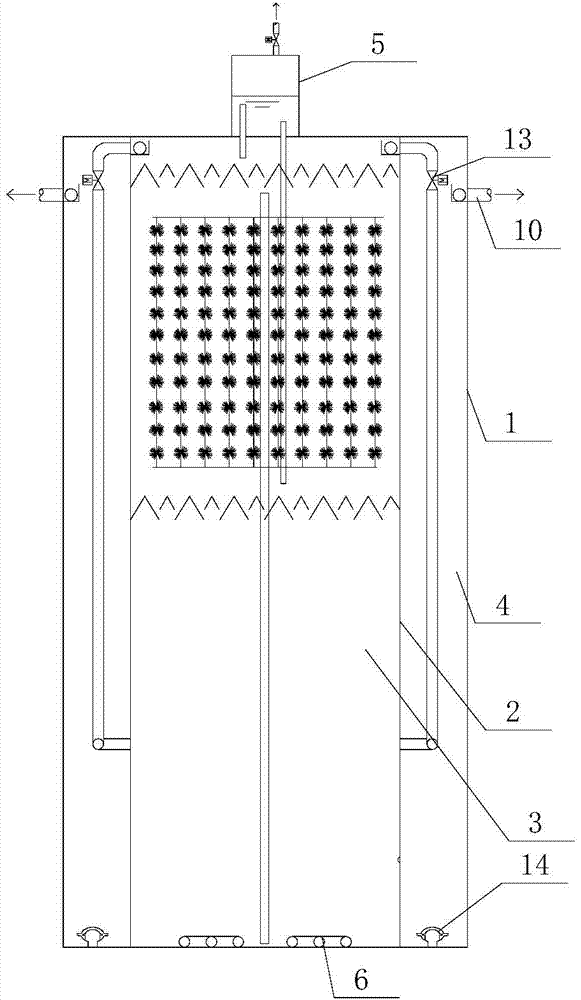

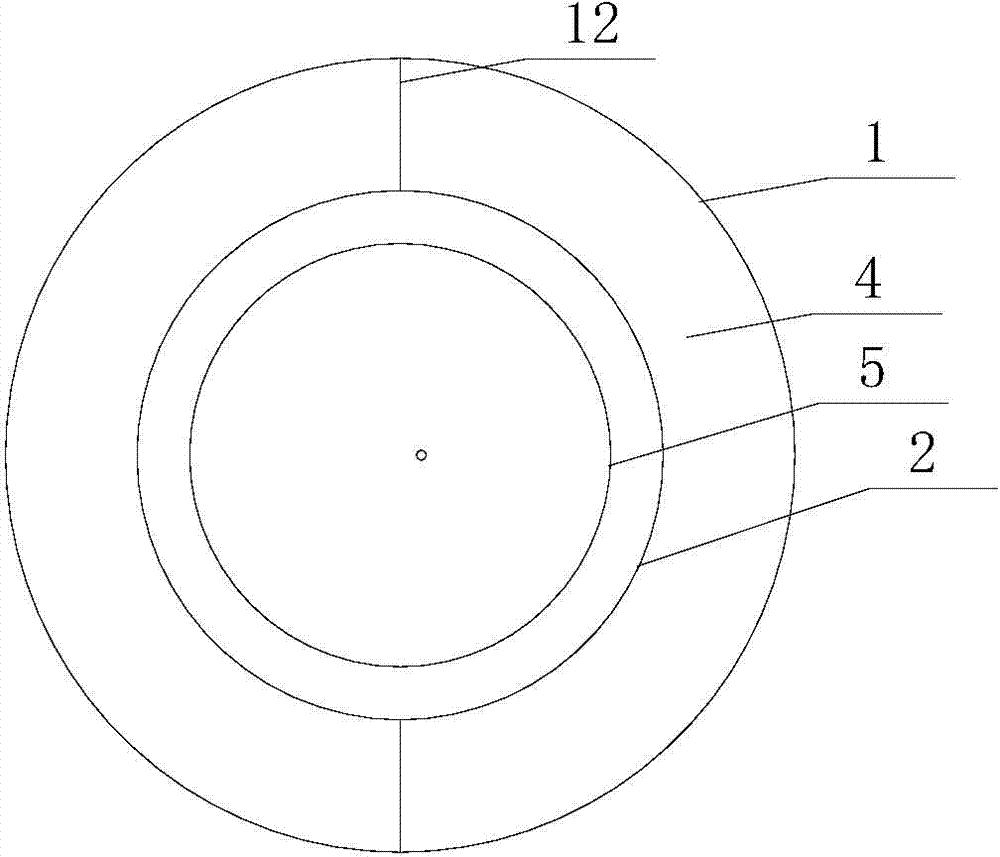

[0038] refer to Figure 1-3 , integrated high-efficiency sewage treatment equipment, including a barrel-shaped tank 1, the barrel-shaped tank 1 is provided with an inner cylinder 2, and the inner cylinder 2 is an anaerobic anaerobic treatment system equipped with an IC anaerobic enhanced treatment system. Zone 3, between the inner cylinder 2 and the barrel-shaped tank 1 is an aerobic zone 4 equipped with an aerobic simplified SBR treatment system, and a biogas connected to the inner cylinder 2 to collect biogas is installed above the inner cylinder 2 Tank 5, the inlet pipe 6 of the IC anaerobic enhanced treatment system is connected to the sewage outlet pumped into the tank by the sump in the factory area, and the outlet pipe 7 of the IC anaerobic enhanced treatment system is connected to the pipeline 8 of the aerobic simplified SBR treatment system , the aerobic simplified SBR treatment system includes a drainage pipe 9 and a sewage pipe 10, and the sewage pipe 10 communicate...

Embodiment 2

[0046] refer to Figure 4 , Figure 5 The difference between the present embodiment and the first embodiment is that the sewage pool 11 communicates with the water inlet pipe 6 of the IC anaerobic enhanced treatment system. Part of the sludge in the sewage tank 11 is returned to the anaerobic zone 3 to supplement the sludge concentration, and the discharged sludge needs to be dried. All the other structures and functions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com