Control method for multi-power source powertrain for vehicle

A technology of powertrain and control method, applied in the field of vehicle transmission control system, can solve the problem of inapplicability of multi-power source powertrain and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

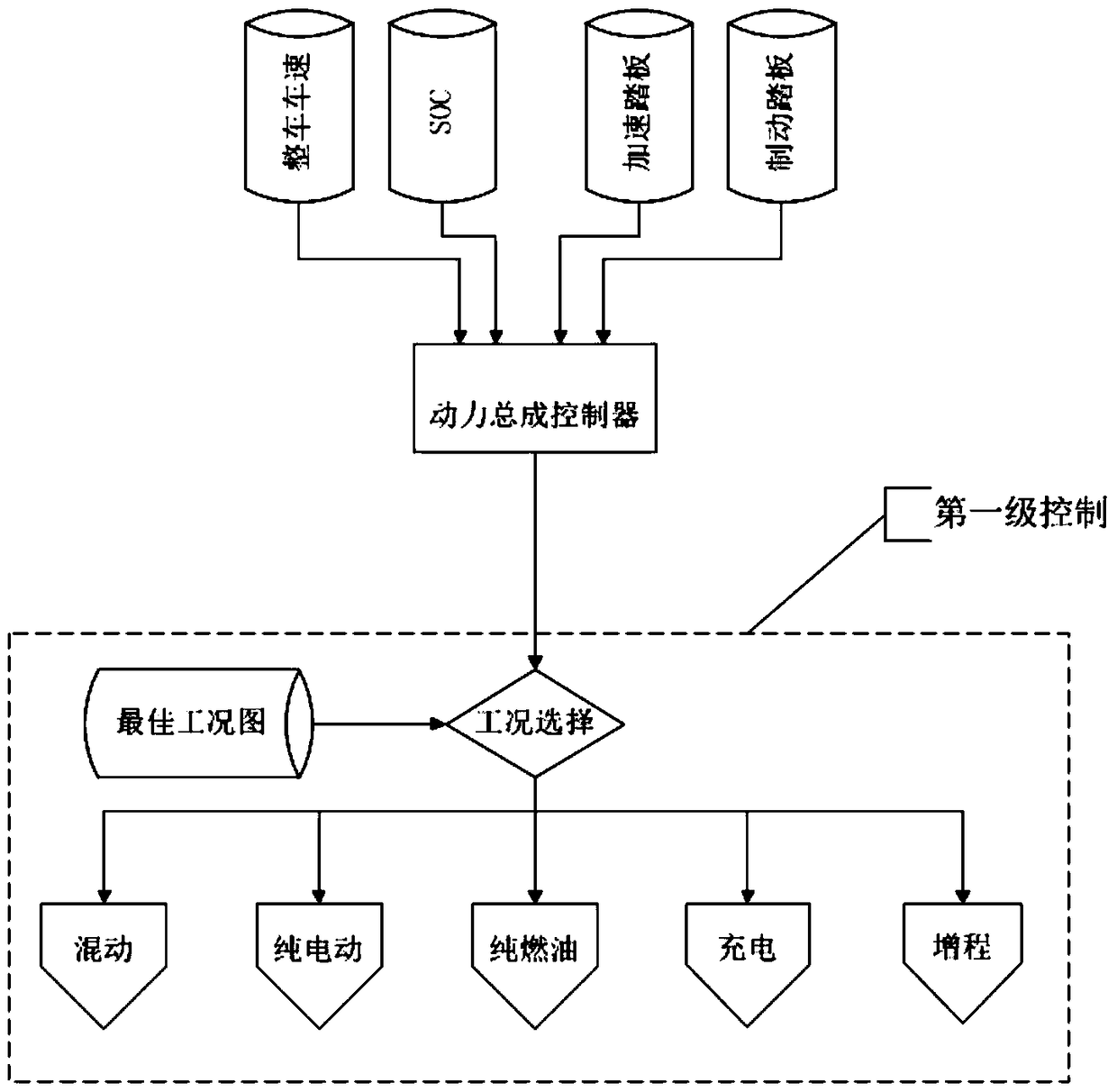

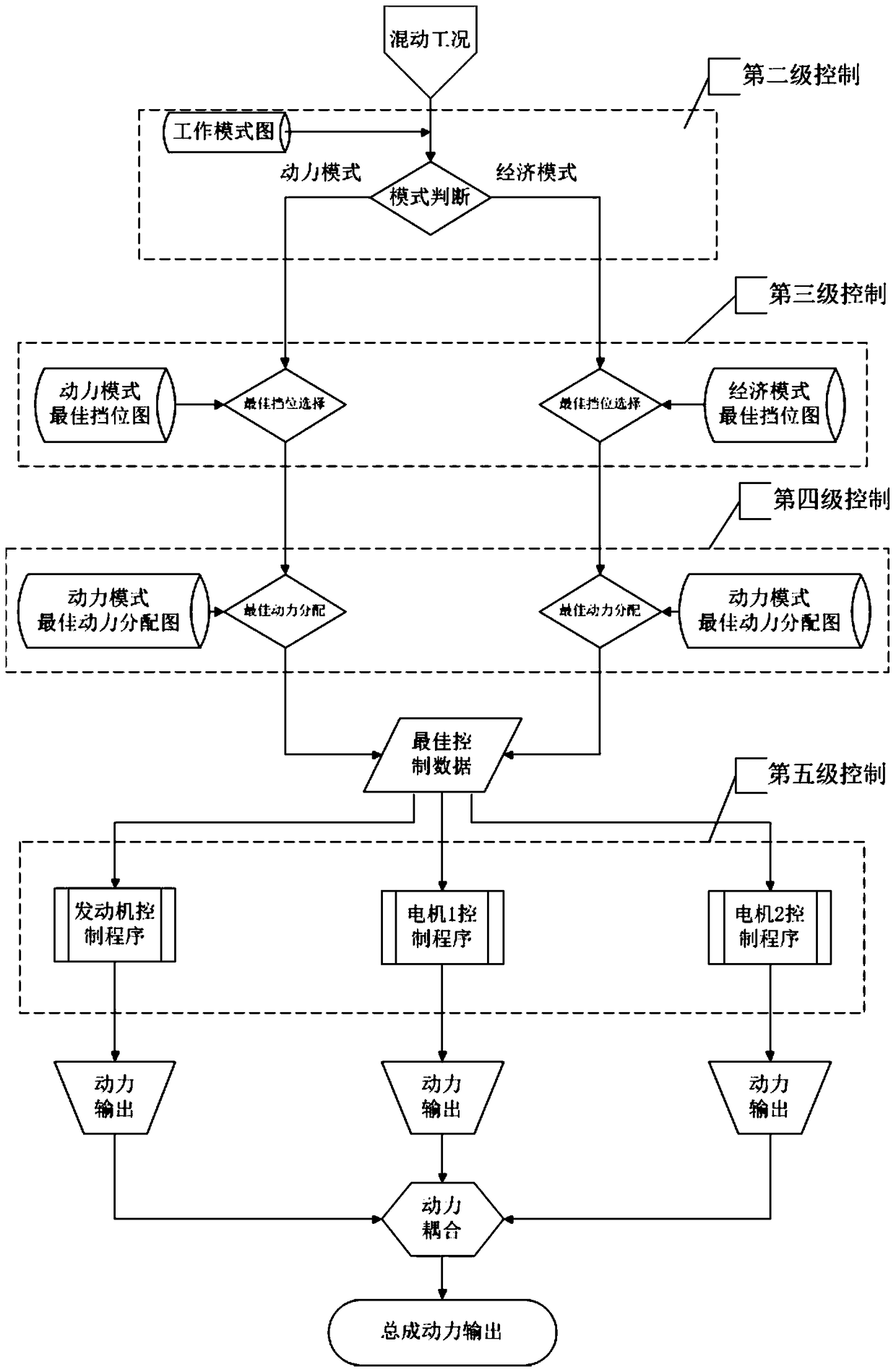

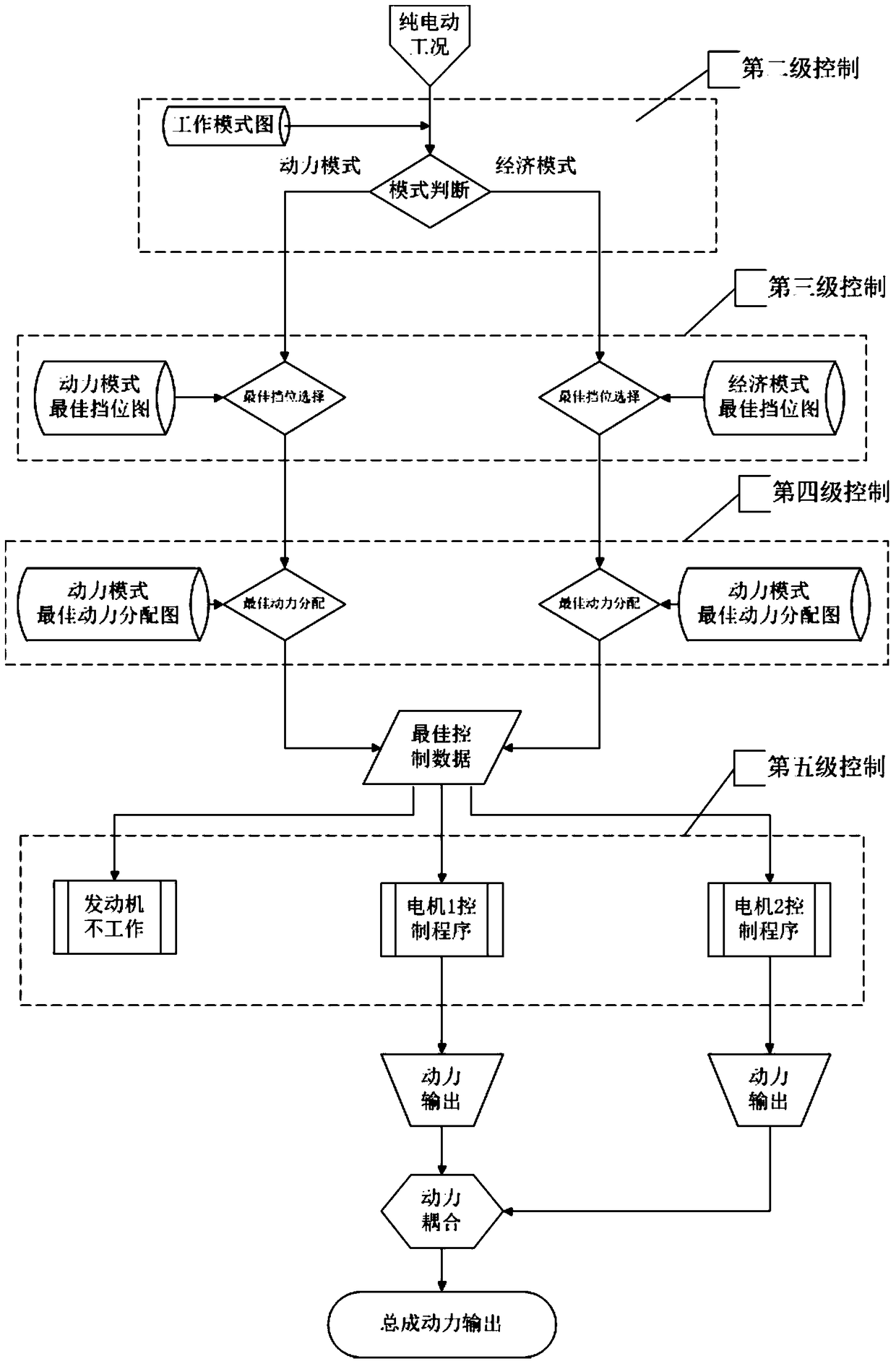

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a control method for a multi-power source powertrain of a vehicle, the multi-power source of the powertrain is an engine and two drive motors, and the working conditions of the powertrain include pure electric working conditions , hybrid working conditions, pure fuel working conditions, charging working conditions and range-extending working conditions; a powertrain controller is provided, and the powertrain controller stores information obtained through a large number of tests and calculations for vehicles under all road conditions. The best working condition diagram, the working mode diagram under each working condition, the optimal gear diagram under each working mode, the optimal power distribution diagram under each working gear, the control program of each power source under each power distribution ; When the electric vehicle is running, the powertrain controller collects ...

Embodiment 2

[0042] Such as Figure 7 As shown, the multi-power source of the power assembly in Embodiment 2 is two driving motors, that is, the engine is canceled, and the multi-power source power assembly becomes a pure electric power assembly composed of two driving motors, and the multi-power The working condition of the source powertrain has also become only one pure electric working condition, and the electric powertrain controller of the multi-power source powertrain does not need to select the working condition, that is, the control method of the multi-power source powertrain Real-time optimal control of multi-power source powertrain can be accomplished only by four-level control.

[0043] In other embodiments, if the number of drive motors in the multi-power source powertrain is reduced to one, the multi-power source powertrain control method in Embodiment 1 only needs to change the number of drive motors to one and update the powertrain The best working condition diagram stored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com