Profiling tool for machining parts and components of ships and method thereof

A technology for parts and tooling, applied in the field of profiling tooling for ship parts processing, can solve the problems of low development level, poor technical level, backward design ability, etc., achieve finishing, reduce production costs, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

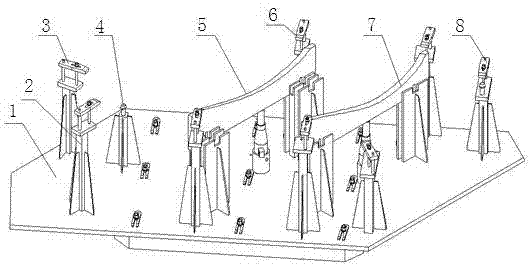

[0011] According to the attached figure 1 The present invention is further analyzed.

[0012] A profiling tool and method for processing ship parts, the tool consists of: a large base plate 1, a tail clamping tool 2, a square window clamping tool 3, a small end bottom support tool 4, a rear profiling plate tool 5, Lumbar support crimping tooling 6, front profiling plate tooling 7 and large end face support crimping tooling 8. After the local support tooling is assembled, it is fixedly connected together through the large bottom plate 1; the tail clamping tooling 2 is clamped through the round hole on the small end face of the workpiece bracket, and its function is to increase the stability when processing the small end face; square window clamping Tooling 3 is clamped by the end face of the small end square window, and its function is to increase the stability of the workpiece bracket during finishing; the small end bottom support tooling 4 is supported by the center round na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com