Technology of using aspergillus oryzae and EM mixed fermentation for producing fermented soybean meal

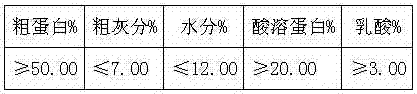

A technology of fermented soybean meal and mixed fermentation, applied in the fields of application, food preparation, food science, etc., can solve the problems of unclear mechanism, insufficient research on the nutritional properties of fermented soybean meal, and great differences in the quality of fermented soybean meal. The effect of improving disease prevention and resistance ability and promoting gastrointestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0047] Implementation case: the process of producing fermented soybean meal by mixed fermentation of Aspergillus oryzae and EM bacteria.

[0048] The process for producing fermented soybean meal by mixed fermentation of aspergillus oryzae and EM bacteria comprises the following process steps: koji making by aspergillus oryzae, mixed inoculation, fermentation and enzymatic hydrolysis, drying and crushing.

[0049] (1) Koji making by Aspergillus oryzae: Mix soybean meal, wheat flour (wheat grains damaged to four to six petals) and water evenly in a weight ratio of 4:1:5, put them in a rotary steamer, and pass them under a pressure of 0.2MPa Steam cooking for 15-20 minutes. After steaming, the material should be cooked but not sticky, and there is no raw core inside. After steaming, when the temperature of the material drops to 40°C, the moisture content is 47%-51%. Inoculate Aspergillus oryzae UE336-2 spore powder between ℃, the inoculation amount is 5‰, transport the inoculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com