A kind of dried peach slices and its preparation process

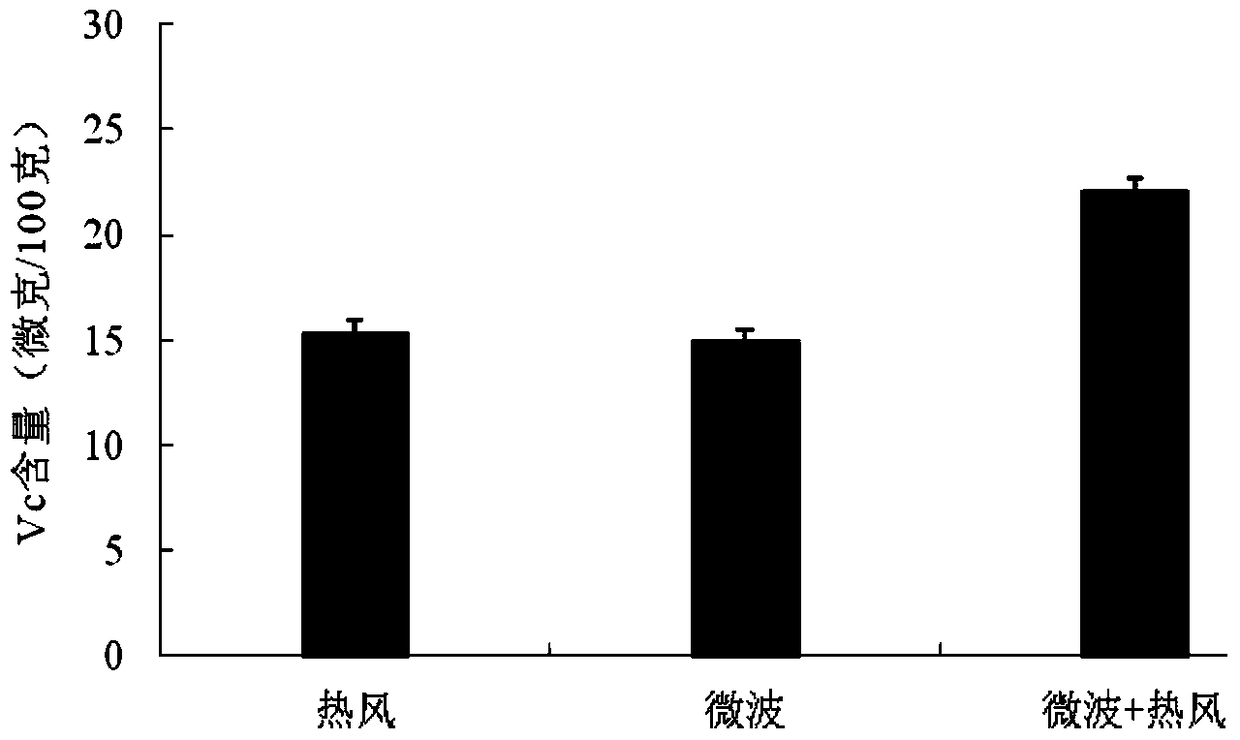

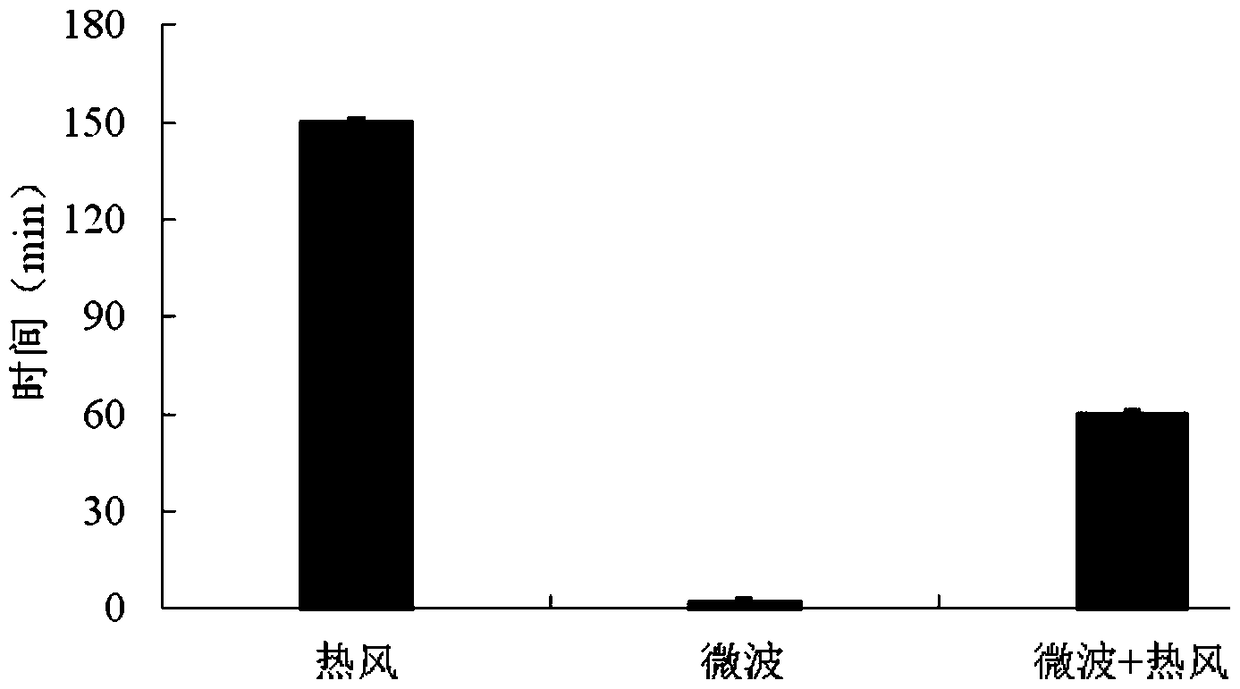

A preparation process and technology for peach slices, which are applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of large loss of aroma, nutrients, long hot air drying time, and product quality decline, and achieve the preservation of Vc content and color preservation. and flavor and quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Choose fresh green peaches with green color, no insect eyes, and no damage. Peel the selected peaches, wash them, and cut them longitudinally. Then take 3.0g±0.1g peach slices with similar shapes and sizes, and put them in In the color-protecting agent, the color-protecting agent is a mixture of 2% NaCl and 0.2% citric acid in mass fraction, the surface of the peach slices is washed with distilled water for more than 3 times, the color-protecting agent is washed off, and then absorbed with absorbent paper. dry surface moisture;

[0027] Step 2: Configure 60% sucrose solution in the Erlenmeyer flask, put the peach slices in the previous step, the mass ratio of peach slices to sucrose solution is 1:10, plug the bottle mouth with a stopper, and place it in a constant temperature shaker to vibrate For osmosis dehydration, set the heating temperature to 50°C and the rotation speed to 120 rpm, let the peach slices permeate and dehydrate for 2 hours, rinse the surface ...

Embodiment 2

[0039] Step 1, as described in Example 1

[0040] Step 2: Configure 60% sucrose solution in the Erlenmeyer flask, put the peach slices in the previous step, the mass ratio of peach slices to sucrose solution is 1:10, plug the bottle mouth with a stopper, and place it in a constant temperature shaker to vibrate For osmosis dehydration, set the heating temperature to 50°C and the rotation speed to 120 rpm, let the peach slices permeate and dehydrate for 2 hours, after taking out, rinse the surface of the peach slices with distilled water for more than 3 times, and dry the surface moisture with absorbent paper;

[0041] Step 3. Spread the peach slices from the previous step in a microwave oven for microwave-assisted drying. Set the power to 200W and dry for 45 seconds. During the drying process, take out the peach slices and turn them over to continue drying. After the semi-finished product is obtained, dry it with hot air and use electric heating to keep the temperature. Dried i...

Embodiment 3

[0043] Step 1, as described in Example 1

[0044] Step 2: Configure 60% sucrose solution in the Erlenmeyer flask, put the peach slices in the previous step, the mass ratio of the peach slices to the sucrose solution is 1:10, plug the bottle mouth with a stopper, and place it in a constant temperature shaker to vibrate For osmosis dehydration, set the heating temperature to 50°C and the rotation speed to 120 rpm, let the peach slices permeate and dehydrate for 2 hours, after taking out, rinse the surface of the peach slices with distilled water for more than 3 times, and dry the surface moisture with absorbent paper;

[0045] Step 3: Spread the peach slices from the previous step on a container and place them in a microwave oven for microwave-assisted drying. Set the power at 150W and dry for 60 seconds. During the drying process, take out the peach slices and turn them over to continue drying to make dried peach slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com