Preparation method of phyllanthus emblica powder

A technology of emblica powder and emblica, applied in food ingredients containing natural extracts, food processing, food drying, etc., can solve the problems of complex discomfort in industrial production, loss of flavor characteristics, high industrial cost, etc., and achieve production intensification and automation High degree, easy operation, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

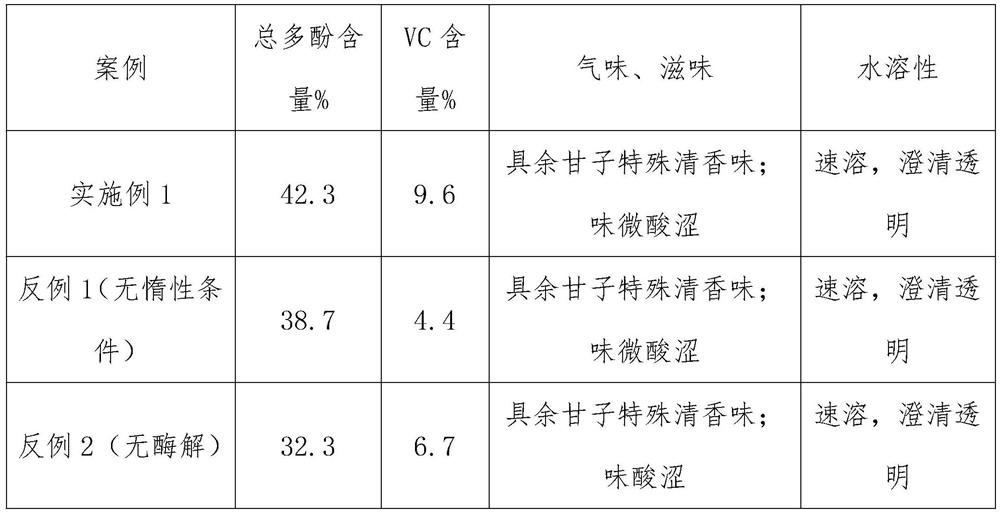

Embodiment 1

[0046] The present embodiment is to prepare the powder of Amla emblica under inert gas conditions:

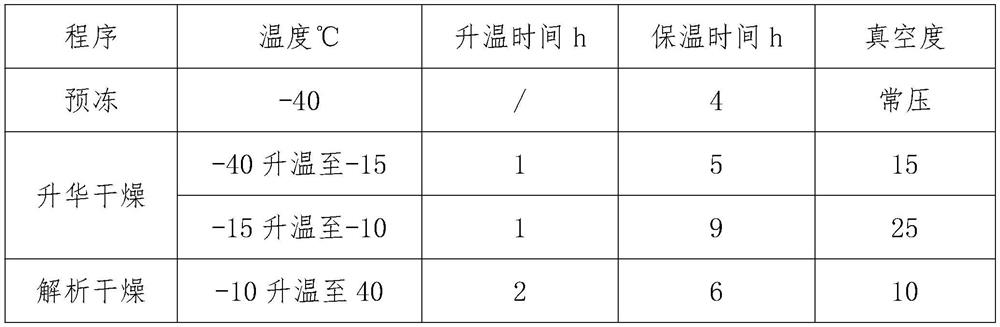

[0047] Take 1000kg of fresh emblica fruit, put it in a fruit beater to beat, collect the slurry, then immediately put the slurry into a multi-functional extraction tank, add 6000L of demineralized water, and continuously inject nitrogen from the bottom of the extraction tank to control the rate of nitrogen introduction 0.5m 3 / min, after displacing the air in the tank, turn on the heating to 55°C and keep it for extraction for 1 hour, then add the extract to the pipeline filter for filtration, filter the extract through a 100-mesh filter bag, and put the filtrate into the storage tank or reaction tank , and then add 2kg of compound enzyme reagent to the filtrate, continuously feed nitrogen from the bottom of the tank, and control the nitrogen feed rate to 0.7m 3 / min, 35 ℃ ~ 45 ℃ heat preservation enzymatic hydrolysis for 2 hours, the enzymatic hydrolysis solution is obtained,...

Embodiment 2

[0053] The present embodiment is to prepare emblica powder in the absence of inert gas conditions:

[0054] Take 1000kg of fresh emblica fruit, put it in a fruit beater to beat, collect the slurry, then immediately put the slurry into a multi-functional extraction tank, add 6000L of demineralized water, turn on the heating to 55°C for 1 hour, and then add the extract Filtrate in a pipeline filter, filter the extract through a 100-mesh filter bag, put the filtrate into a storage tank or a reaction tank, then add 2kg of compound enzyme reagent to the filtrate, and heat it at 35°C to 45°C for 2 hours to obtain the enzymolysis solution. Afterwards, the enzymatic solution was filtered through a pipeline filter with a built-in 5 μm filter bag, and then filtered through a ceramic membrane device with a built-in 200nm ceramic membrane. The nanofiltration membrane equipment is concentrated to a relative density of 1.08. The obtained concentrated liquid flows into the 100,000-class clea...

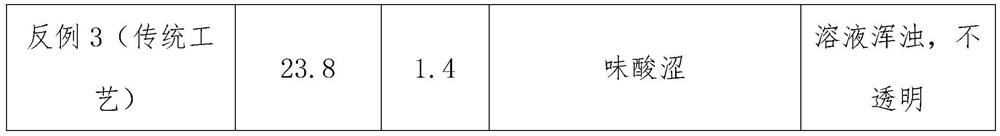

Embodiment 3

[0061] This embodiment is to prepare Emlical seed powder without using compound enzyme reagent:

[0062] Take 1000kg of fresh emblica fruit, put it in a fruit beater to beat, collect the slurry, then immediately put the slurry into a multi-functional extraction tank, add 6000L of demineralized water, and continuously inject nitrogen from the bottom of the extraction tank to control the rate of nitrogen introduction 0.5m 3 / min, after displacing the air in the tank, turn on the heating to 55°C and keep it for extraction for 1 hour, then add the extract to the pipeline filter for filtration, filter the extract through a 100-mesh filter bag, and put the filtrate into the storage tank or reaction tank , the filtrate is filtered through a pipeline filter with a built-in 5μm filter bag, and then filtered through a ceramic membrane device with a built-in 200nm ceramic membrane. Membrane equipment concentrates to a relative density of 1.08. The obtained concentrate flows into the 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com