Large-discharge-interval normal temperature glow discharge low-temperature plasma material processing device

A low-temperature plasma and glow discharge technology, applied in the direction of plasma, electrical components, etc., to achieve the effect of low vacuum degree requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

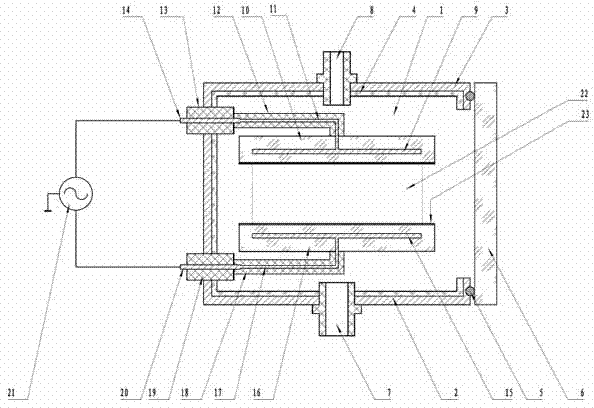

[0038] figure 1 It is an embodiment of the patent of the present invention. In order to prevent the electrodes and the vacuum cavity wall from discharging, the cavity wall of the vacuum cavity 1 in this embodiment adopts an insulating cavity wall 2, and the insulating material of the insulating cavity wall 2 can be ceramics, glass , polyethylene, polyvinyl chloride, polypropylene, polytetrafluoroethylene, nylon and other materials. The right side of the vacuum chamber body 1 is a vacuum chamber door 6, which can be made of tempered glass, and a sealing ring 5 is arranged between the vacuum chamber door 6 and the chamber body. The lower cavity wall is provided with an air extraction and deflation interface 7, and the upper cavity wall is provided with an external atmosphere interface 8. The upper electrode 9 and the lower electrode 15 are arranged in the vacuum chamber 1 opposite to each other. The upper electrode 9 is connected to the (+) end of the differential modulation pu...

Embodiment 2

[0044] figure 2 It is the second embodiment of the present invention. The cavity wall of the vacuum cavity 1 in this embodiment is a metal cavity wall 3. In order to prevent the electrodes and the metal cavity wall 3 from discharging, the inner surface of the metal cavity wall 3 is covered There is an insulating layer 4, and the metal cavity wall insulating layer 4 has adopted materials such as glass, polyethylene, polypropylene, nylon, polytetrafluoroethylene, silicon rubber and the like. The other structure of this embodiment is the same as that of Embodiment 1, and its operation method is also the same as that of Embodiment 1 during specific implementation. This embodiment is suitable for equipment with a relatively large volume of the vacuum cavity 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com