Modular multilevel voltage source converter valve hall

A modular multi-level, voltage source converter technology, applied in the direction of electrical components, output power conversion devices, etc., can solve the problems of increased space occupation, cost of supporting devices, complicated connections, etc., to save space. The effect of ground space, convenient connection and simplified connection difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] In order to solve the cumbersome layout of the main circuit of the valve hall and the problem of space occupation, the present invention proposes the following scheme:

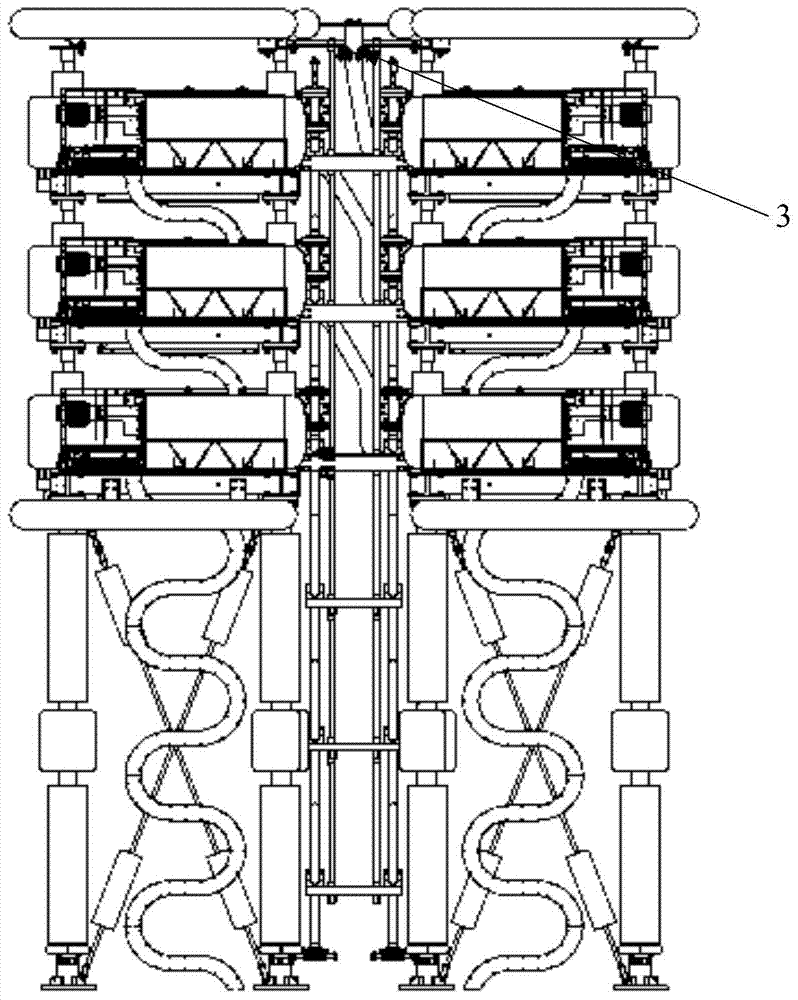

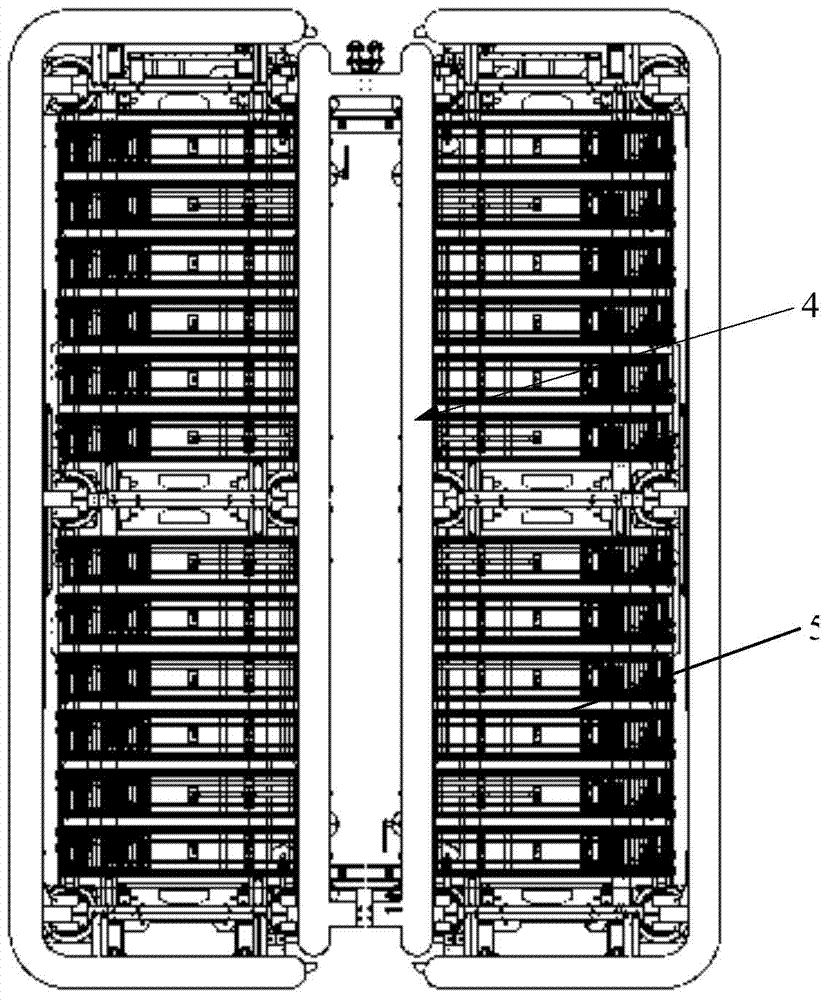

[0025] The fittings installed at the bottom of the valve tower are connected to the busbar of the valve module, and are within the surrounding area of the shielding cover of the valve tower, and there is no need to design the shielding cover to equalize the pressure of the fittings. The primary current flows through the pressure equalizing ring at the top of the valve tower. The specific method is: the outlet busbar of the last valve module on the top of the valve tower is directly connected to the pressure equalizing ring on the top of the valve tower; As the outlet end at the top of the valve tower. In this way, the inlet and outlet lines of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com