Manufacturing procedure of electronic substrate, manufacturing procedure of display panel and applied adhesive

A technology for electronic substrates and display panels, applied in the field of adhesives used in this process, can solve the problem of low process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The designated representative in this case is Figure 6 .

[0038] A brief description of the symbols in this representative diagram:

[0039] S601 equipped with hard substrate

[0040] S603 Coating liquid adhesive

[0041] S605 Form adhesive dry film

[0042] S607 adheres to the base material and forms two panel modules

[0043] S609 Combining two panel modules and the display material in them

[0044] S613 combined to form a display panel

[0045] S615 Irradiating light to remove adhesiveness

[0046] S617 Remove hard substrate and adhesive dry film

[0047] S619 forming display panel

[0048] The chemical formula that best shows the characteristics of the invention:

[0049]

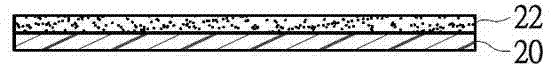

[0050] This specification is about the manufacturing process of an electronic substrate, the manufacturing process of a display panel and the adhesive used. The adhesive used in the manufacturing process has photosensitive properties, and one of its properties is to remove solvents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com