Gas chromatograph for gas analysis in production field

A gas chromatograph, gas analysis technology, applied in the direction of analysis materials, instruments, scientific instruments, etc., can solve the problems of high price of imported instruments, high production cost, complex structure, etc., achieve strong impurity adsorption capacity, good thermal stability, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

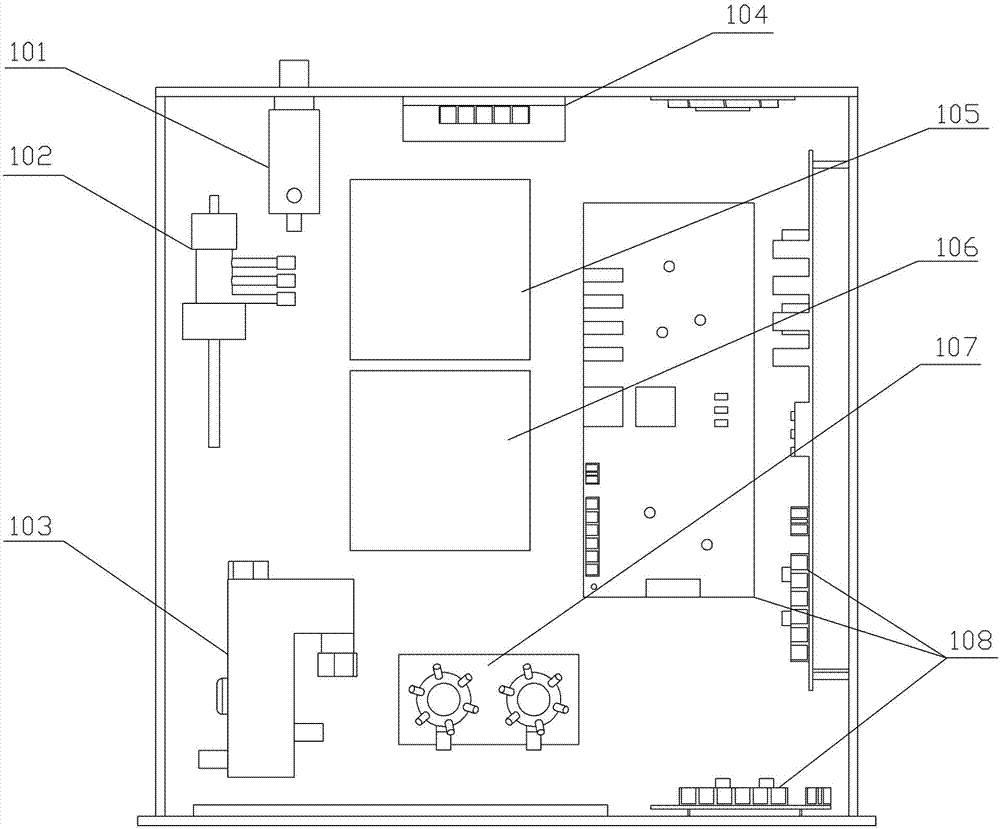

[0025] According to attached Figure 1~3 , The present invention is a gas chromatograph for gas analysis on the production site, comprising a sampling unit, a gas circuit control unit, a circuit control unit, a separation unit, a detection unit and a data processing unit.

[0026] According to attached figure 1 , The shell of the present invention is made of a 420mm long, 430mm wide, 5U (222mm) aluminum alloy chassis, the upper cover can be opened, and the bottom is a layer of mounting base plate for installing all parts of the present invention. The front panel can be disassembled separately, and there are four screws on the left and right sides of the chassis to easily disassemble the front panel, which is convenient for the installation and maintenance of the embedded computer.

[0027] The gas circuit control unit is connected to a high-precision solid filter 206 after the carrier gas (i.e. high-purity helium) enters the chassis, followed by a stainless steel diaphragm reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com