Gear single-tooth loading testing device with uniform loading function

A loading test device, gear unit technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of high-end gear product constraints, lack of basic test data, large errors, etc. discrete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiments (accompanying drawings).

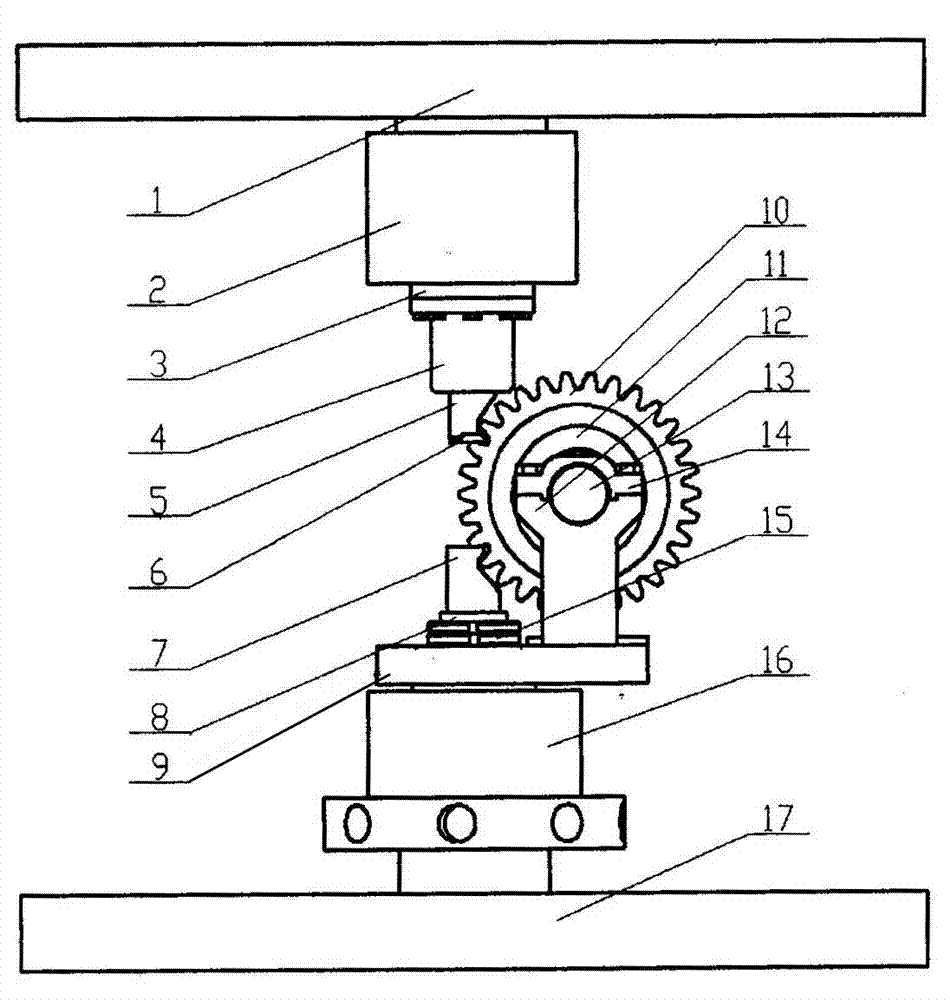

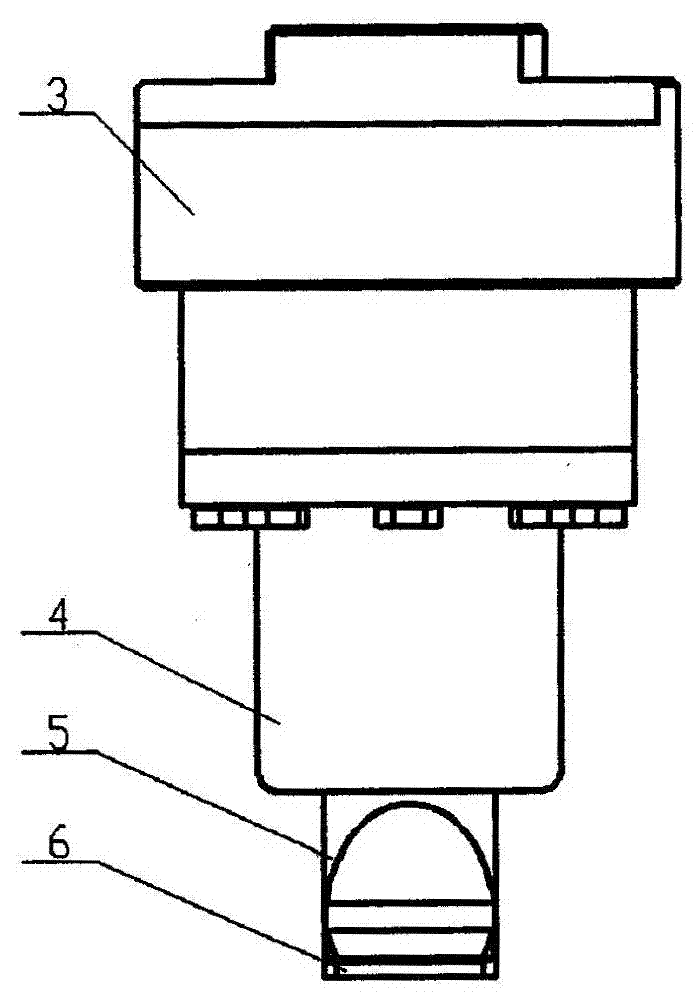

[0028] Such as figure 1 and figure 2 As shown, the gear single-tooth loading test device with load equalizing function of the present invention includes two parts: a support structure and a loading structure located above the support structure; , positioning ring 11, support frame 12, mandrel 13, shaft gland 14; the lower end of the support head 7 is fixed on the support base 9; 15 The fixed plate 12-2 fixedly installed on the support base 9, the adjustable support 12-1 installed in the guide groove processed on the fixed plate, the positioning pin 12-1 arranged between the fixed plate and the adjustable support 3 and deadbolt 12-4 (see Figure 8-10 ); the supporting base 9 is integrated with the lower bed 17 through the large nut 16 of the lower bed, and the test gear 10 is installed on the top of the adjustable bracket 12-1 through the positioning rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com