A model box with high confining pressure loading system

A loading system and high confining pressure technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem that the model box cannot simulate vibration experiments, etc., to reduce experimental costs, reduce self-weight, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

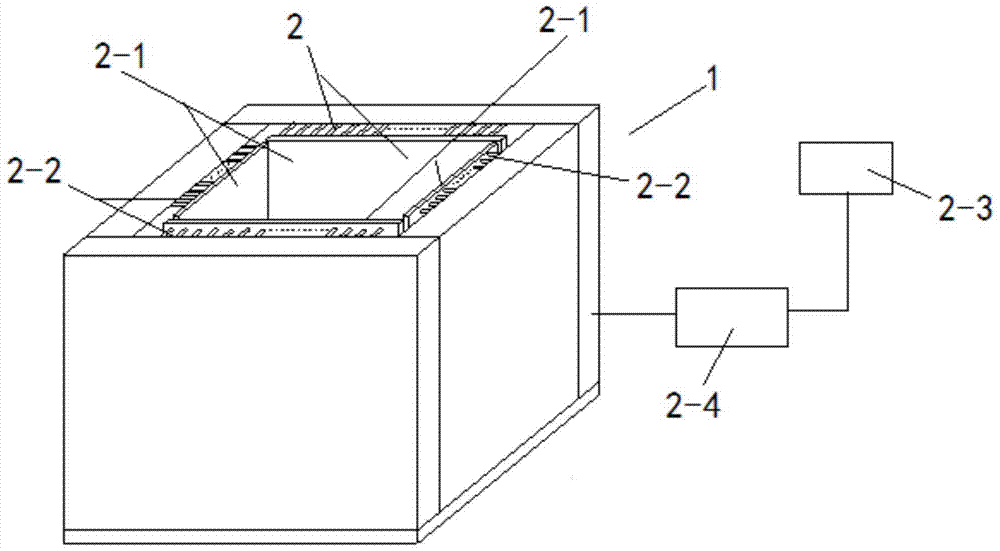

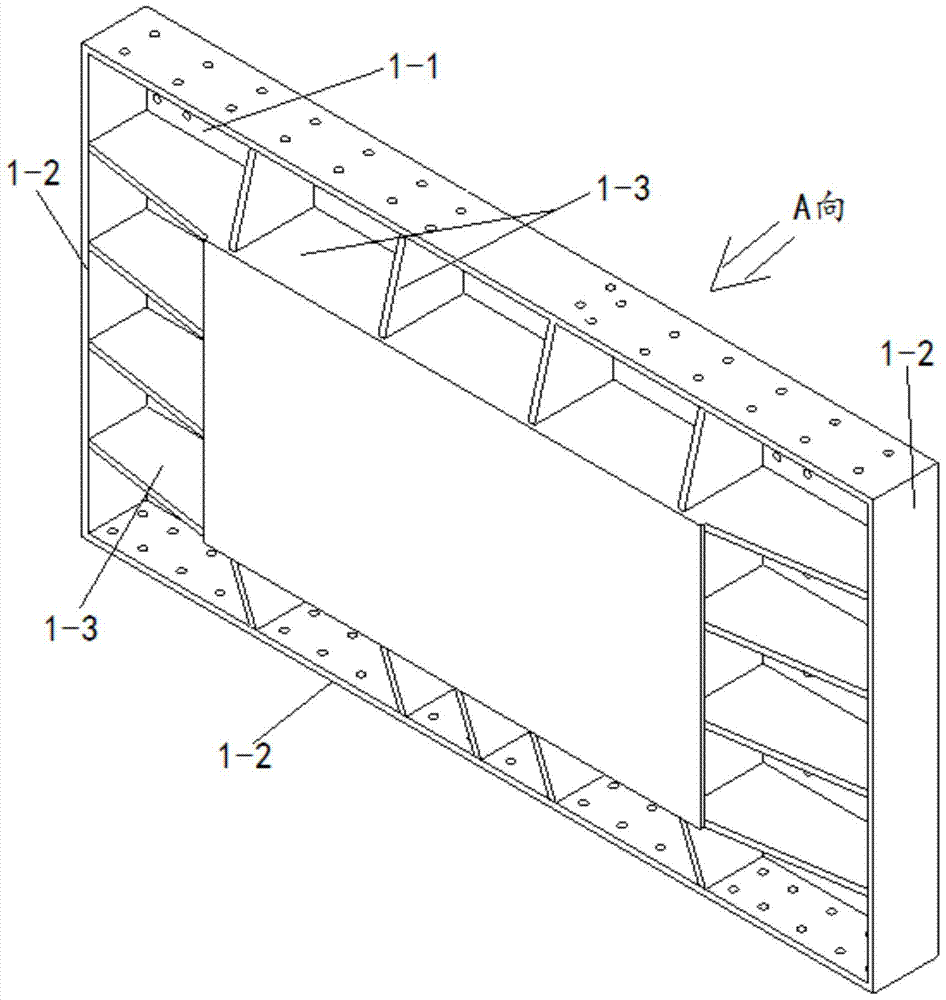

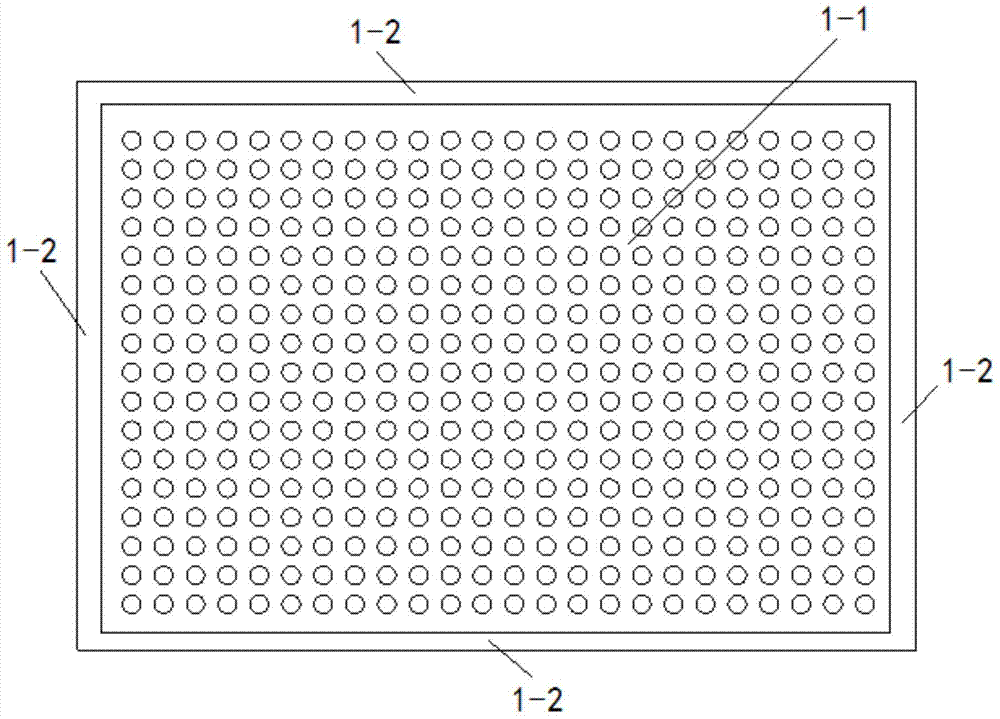

[0056] Considering the purpose and reference equipment, the model box is designed. The maximum volume size of the model box is 3m×2m×2m. The actual experiment needs to adjust the volume size of the inner cavity, the total weight is less than 8T, and the overall structure is as follows Figure 4 As shown, in order to make the box body structure more firm, the present invention is fastened with right-angle pull plate 1-4 and peripheral auxiliary supporting plate 1-5 at four right angles of the upper end surface of the model box, and the setting of right-angle pull plate helps After anchoring the lightweight and high-strength box wall after adjusting the size, the setting of the peripheral auxiliary support plate helps to feed back the load evenly to the experimental sample. In addition, the ribs of the light-weight and high-strength box wall of the present invention are designed in a window format. The design of the window-style rib structure can not only distribute the load eve...

Embodiment 2

[0061] Figure 8 As shown, in this embodiment, on the basis of Embodiment 1, a dowel bar CG is added between the oil cylinder and the baffle. Expand the scope of application of the present invention. In addition, the experiment shows that after the oil cylinder is loaded, the load can be fully transmitted to the baffle plate through the dowel rod, and then acted on the soil sample, which fully meets the experimental requirements. Furthermore, the use of the dowel bar can also greatly reduce the box loss of the model box. In the next test, only the baffle and the dowel bar need to be replaced, which reduces the cost of the experiment and is highly sustainable.

[0062] In order to further reduce the overall weight of the entire model box, the oil cylinder used in this embodiment is made of aluminum alloy, with a maximum stroke of 60mm, a rated operating pressure of 25MPa, and a maximum output of 4.9T. The front and rear baffles are each equipped with 88 oil cylinders, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com