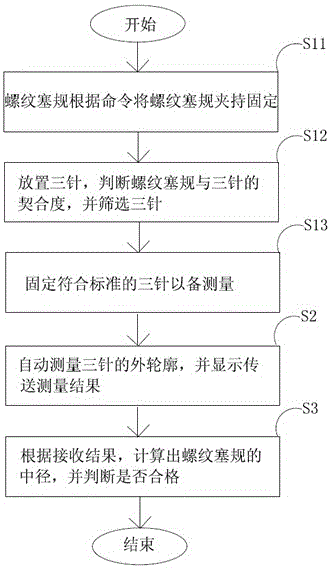

Automatic detection method and device for thread plug gauge

A threaded plug gauge and automatic detection technology, applied in the direction of plug gauges, measuring gauges, etc., can solve problems such as the inability to guarantee the fit accuracy of the three-pin and threaded plug gauge teeth, poor contact at three contact points, and inconvenient verification and measurement, etc., to achieve The effect of avoiding errors, reducing requirements, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

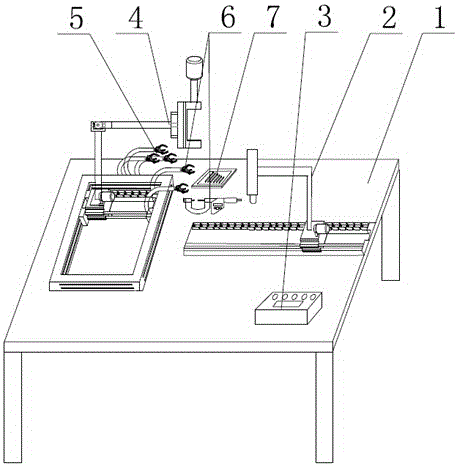

[0026] The invention discloses an automatic detection device for threaded plug gauges, as attached figure 2 As shown, it includes a frame 1, and also includes a control host 3 set on the frame 1, a threaded plug gauge clamping device 4, a three-needle placement device 5, an automatic measuring device 6, and a set of threaded plug gauges that match each type The three needles 7; because the pitches of different thread plug gauges correspond to different three needles 7, the device also includes an induction detector 2 for measuring the coordinate information of the three needles 7, and the induction detector 2, in this embodiment Among them, a three-coordinate detector is preferred, and the control host 1 is electrically connected to the threaded plug gauge clamping device 4, the three-needle placement device 5, the automatic measuring device 6 and the three-coordinate detector, respectively, and controls their work respectively.

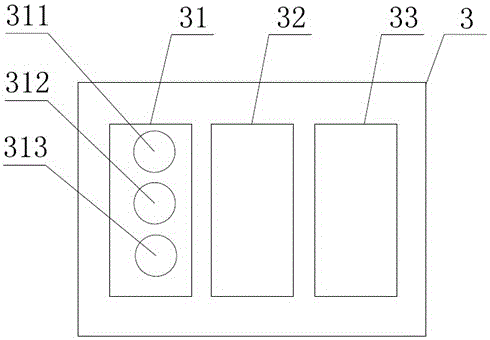

[0027] as attached image 3 As shown, wherei...

Embodiment 2

[0036] The overall structure of this embodiment is similar to that of Embodiment 1. The difference is that the three needles 7 are a set of needle-shaped sensing detection devices capable of sensing their own coordinate information. On this basis, the original common three needles 7 can be omitted. The needle 7 and the three-coordinate detector are more streamlined in structure; during testing, after the needle-shaped induction detection device is placed in the groove of the threaded plug gauge through the three-needle placement device 5, the needle-shaped induction detection The device can automatically obtain its own coordinate information, and can transmit data to the control host 3 via bluetooth, wireless, etc. for calculation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com