Jet engine cleaning method and cleaning apparatus

A jet engine and cleaning device technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as inability to achieve the effect, achieve the effect of shortening the cleaning time, reducing the processing cost, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

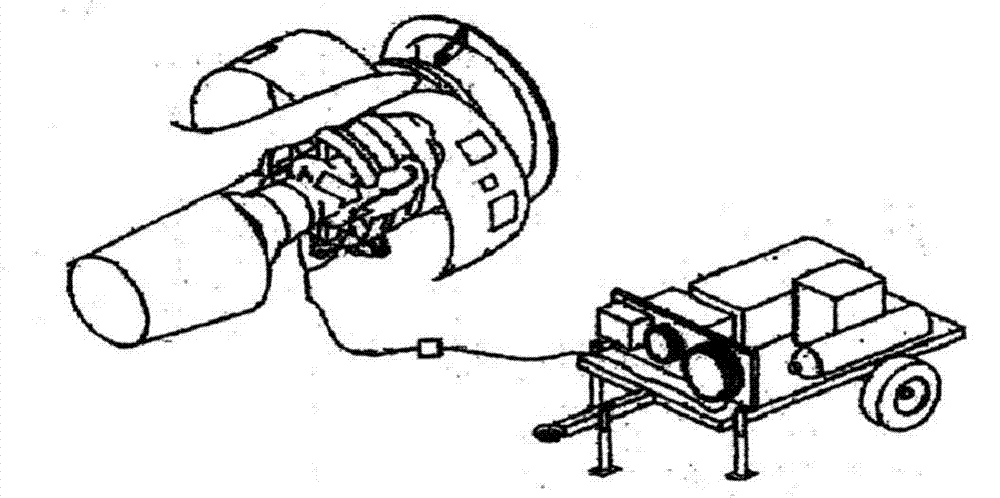

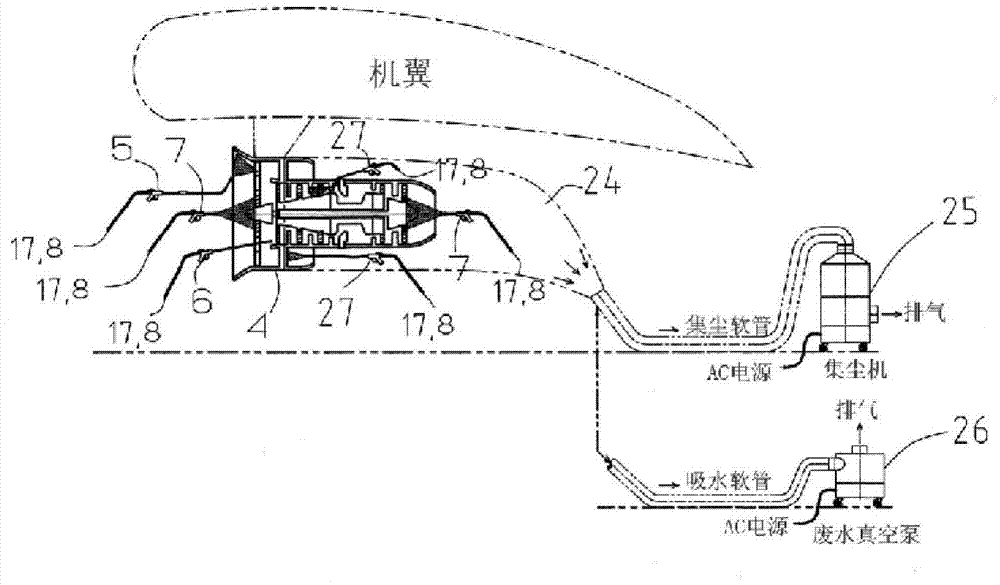

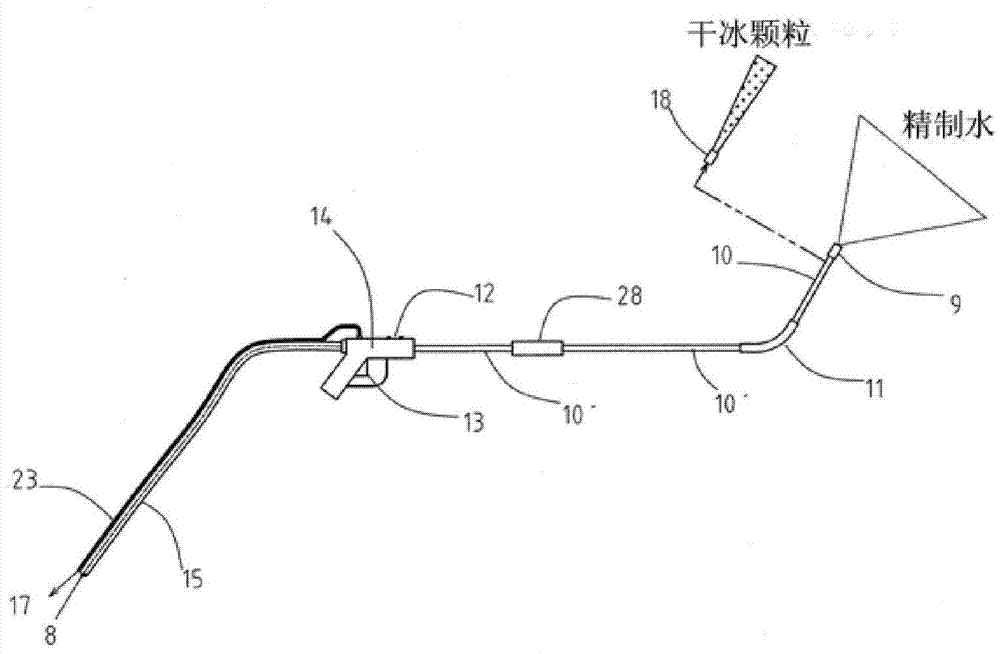

[0048] Embodiments of the present invention will be described below with reference to the drawings.

[0049] figure 2It is a figure showing one embodiment of the present invention, and shows a spray head device 5 for cleaning the inner wall surface of the front blade, a stationary wing, and a moving wing with dry ice particles, a spray head device 6 for cleaning the front blade, and a spray head device 7 for cleaning the inside of the engine , and with the spray head arrangement 27 having the flexible tube 16 for cleaning the jet engine 4 example. In the above embodiment, the nozzle device 27 is inserted from the optical fiber inspection port, and sprays dry ice particles, purified warm water (70° C. to 80° C.) and purified water for rinsing for cleaning. in addition, figure 2 Symbol 8 represents a device in which dry ice particles, purified warm water or purified water for rinsing are injected into the injector 14, and the sand or dust peeled off after cleaning with dry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com