The upper and lower connection structure of the prefabricated shear wall

A technology for connecting structures and shear walls, which is applied in the direction of walls, building components, and building structures, and can solve problems such as stress concentration at horizontal joints, difficulty in ensuring the quality of reserved holes, and difficulty in welding quality , to achieve good development prospects, solve construction difficulties, accurate positioning and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

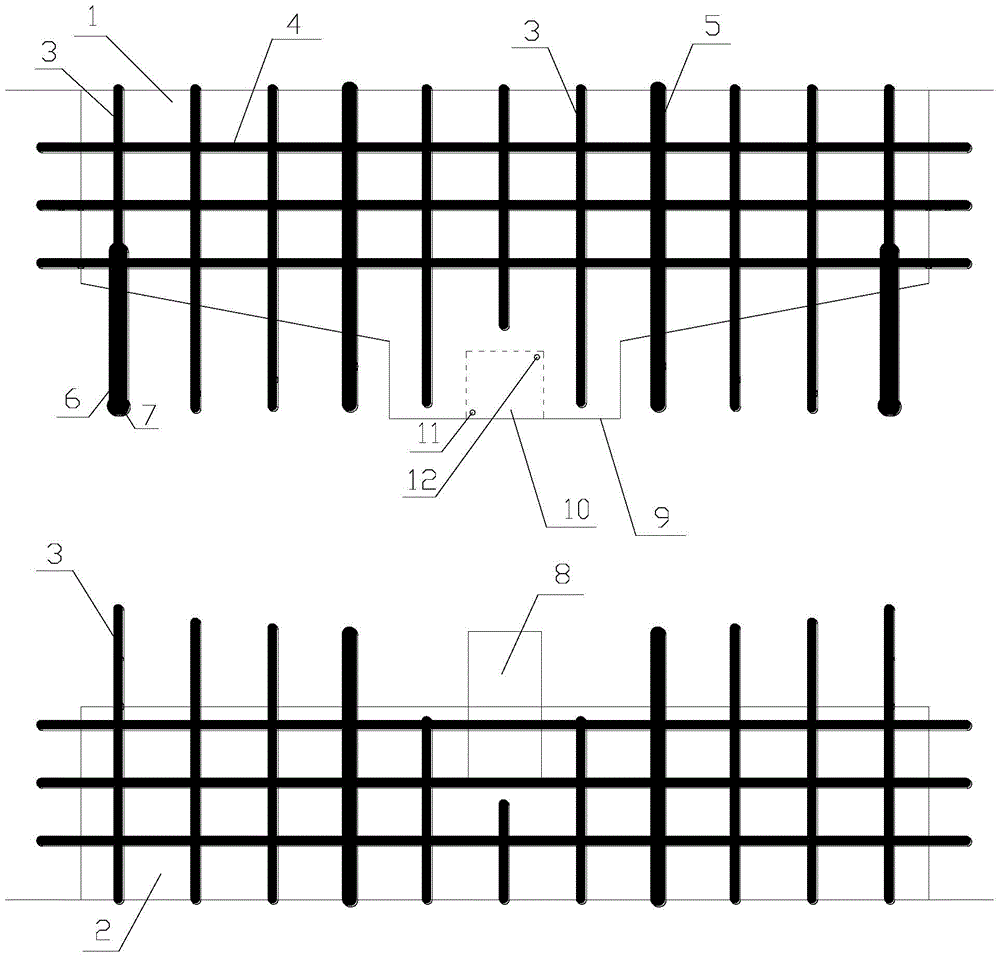

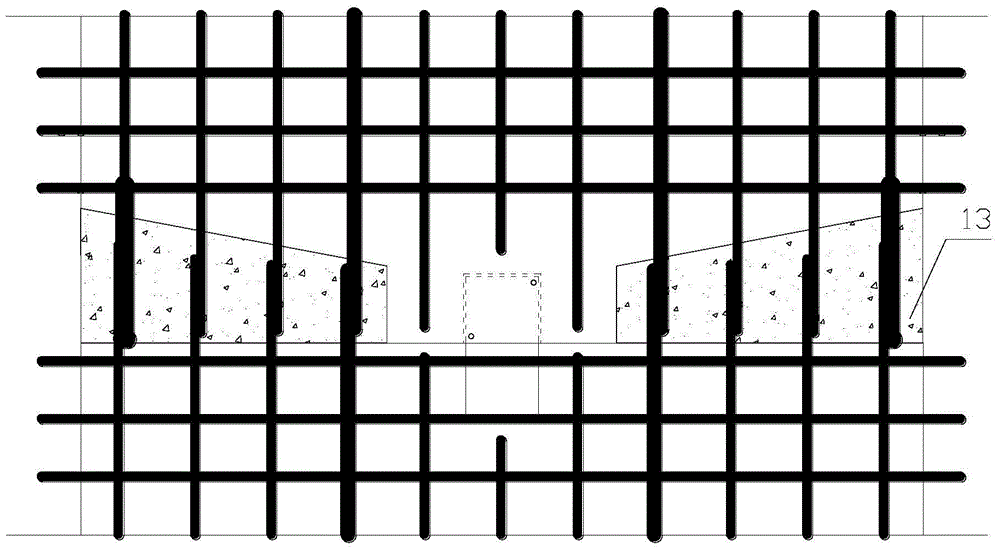

[0022] see Figure 1 to Figure 6 , a lower connection structure of a prefabricated shear wall, the middle part of the bottom surface of the upper wall is provided with a downward protruding platform 9, and a shear groove 10 is provided on the bottom surface of the downward protruding platform 9; the lower wall I-beam 8 is pre-buried in the middle of the top surface of 2; said downward protruding platform 9 is located on the top surface of said lower wall 2, and said I-beam 8 is inserted into said shear groove 10, The I-beam 8 is fixed in the shear groove 10 by the concrete structure poured into the shear groove 10 to form a positioning-shear structure.

[0023] In this embodiment, the bottom surface of the upper wall 1 located on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com