Thermal conductive adhesive composition for measuring temperature of cable and application method of thermal conductive adhesive composition

A technology of heat-conducting adhesives for temperature measurement, applied in the direction of adhesive types, adhesive additives, ester copolymer adhesives, etc., can solve the problems of long response time of temperature measurement, small contact area, decreased sensitivity, etc., and achieve good Heat insulation, large contact area for temperature measurement, and increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of acrylate resin solution is:

[0034] First put 1 / 3~1 / 2 organic solvent into the reaction kettle, and raise the temperature to 85±2°C, while controlling the stirring speed at 100~700rpm, and then completely dissolve each acrylic acid monomer and initiator in the remaining organic solvent , and then drop it into the reactor at a rate of 2 to 6 seconds per drop. After the drop is completed, keep it warm for 3 to 6 hours, stop the reaction, and discharge it at room temperature;

[0035] The organic solvent among the present invention is preferably one or more in ethyl acetate, butyl acetate, acetone, butanone, xylene.

[0036] The heat-conducting inner glue is prepared by fully stirring 70-100 parts of acrylate resin solution, 20-50 parts of heat-conducting powder and 1-15 parts of additives, wherein the average particle size of the heat-conducting powder is not greater than 6 microns;

[0037] The sealing and heat-insulating outer glue is prepare...

Embodiment 1

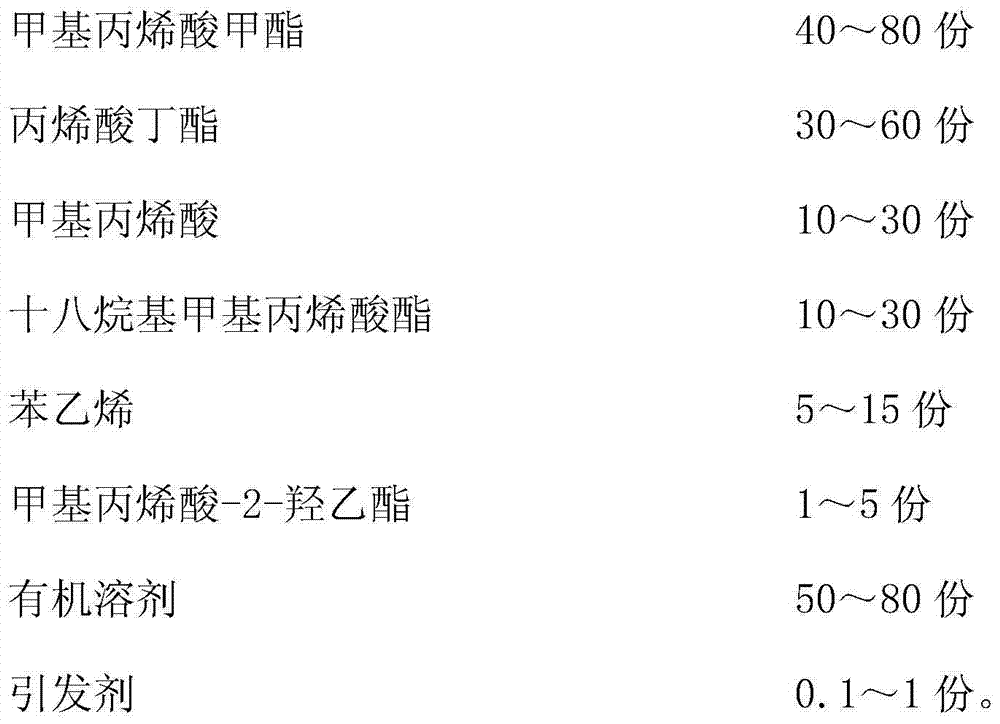

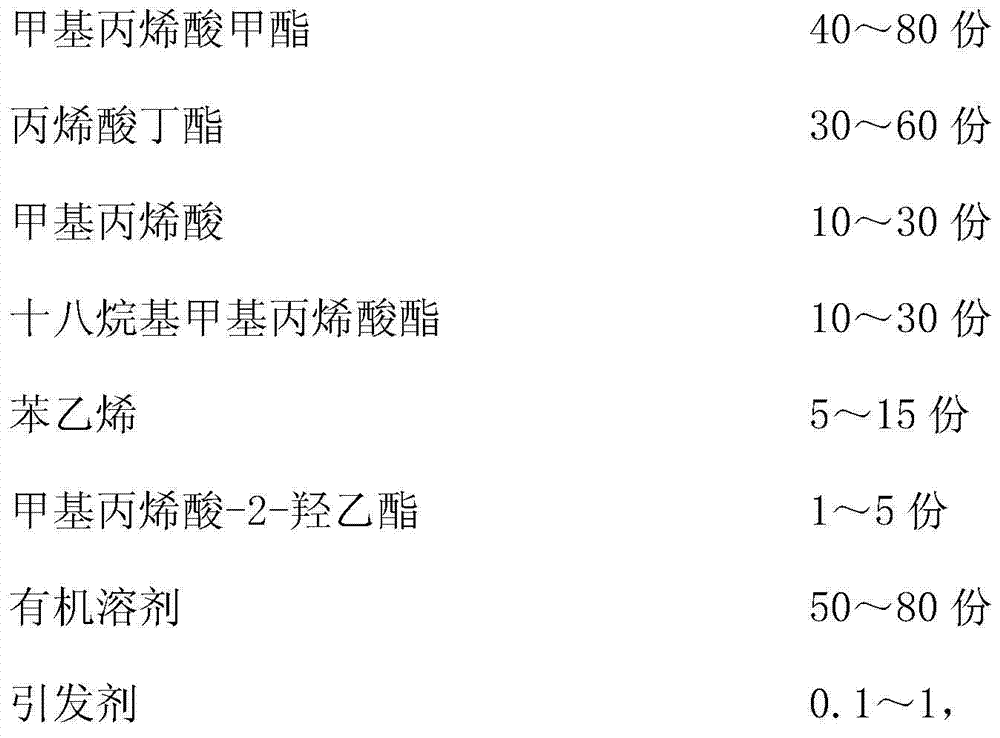

[0042] Prepare the Acrylate Resin Solution

[0043] Put 1 / 3 of the organic solvent into the reaction kettle according to the following proportions by weight, and raise the temperature to 85±2°C, while controlling the stirring speed to 100rpm, and then completely dissolve each acrylic acid monomer and initiator in the remaining organic solvent , and then drop it into the reaction kettle at a rate of 2 to 6 seconds per drop. After the dropwise addition, keep it warm for 3 hours, stop the reaction, and discharge it at room temperature:

[0044]

[0045]

Embodiment 1-1

[0048] a. Preparation of thermal inner glue

[0049] Fully stir 70 parts of acrylate resin solution, 20 parts of silver powder and 1 part of coupling agent KH550 evenly;

[0050] b. Preparation of sealing and heat insulating outer glue

[0051] Mix 70 parts of acrylate resin solution, 30 parts of nano-scale ATO and 1 part of curing agent melamine fully and evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com