Novel antibacterial and deodorant PVC shoe material and preparation method thereof

A PVC resin and anti-odor technology, applied in shoe soles, footwear, applications, etc., can solve the problems of short duration of antibacterial performance of shoe sole materials, weak combination of antibacterial agents and shoe materials, sweat cannot be eliminated in time, and achieve raw material prices Inexpensive, non-toxic and side effects, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

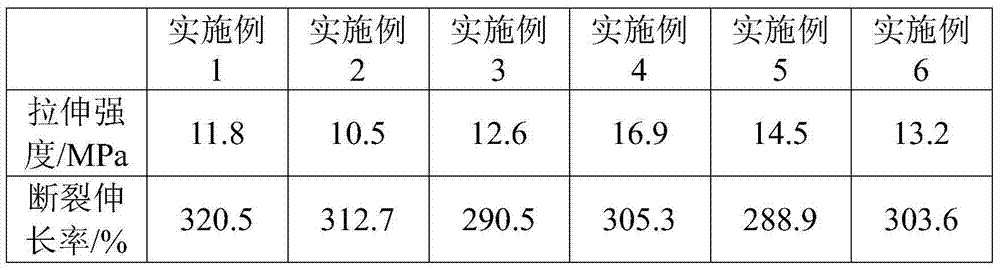

Examples

Embodiment 1

[0037] A novel antibacterial and deodorant PVC shoe material, in parts by weight, comprises the following components:

[0038] 15 parts of PVC resin,

[0039] 5 parts of dibutyl phthalate,

[0040] 3 parts of hollow glass microspheres, 8 parts of rhubarb,

[0041] 2 parts honeysuckle, 1 part cork, 5 parts mint,

[0042] 2 parts of stabilizer, 1 part of crosslinking agent, 3 parts of foaming agent.

[0043] Its preparation method comprises the following steps:

[0044] (1) Dried 8 parts of rhubarb, 2 parts of honeysuckle, 1 part of Phellodendron cortex, and 5 parts of mint in the sun, crushed them, added absolute ethanol solution, and ultrasonicated for 2 hours at a power of 800W to obtain a mixed material, and transferred the mixed material to a reflux device In a three-necked flask in the middle, at 60°C and 2000 rpm, reflux and stir for 1 hour, cool to room temperature, and filter to obtain a Chinese herbal medicine extract;

[0045] (2) Add 3 parts of hollow glass micr...

Embodiment 2

[0049] A novel antibacterial and deodorant PVC shoe material, in parts by weight, comprises the following components:

[0050] 45 parts of PVC resin,

[0051] 10 parts of dibutyl phthalate,

[0052] 8 parts of hollow glass microspheres, 15 parts of rhubarb,

[0053] 6 parts of honeysuckle, 8 parts of cork, 10 parts of mint,

[0054] 5 parts of stabilizer, 3 parts of crosslinking agent, 5 parts of foaming agent.

[0055] Its preparation method comprises the following steps:

[0056] (1) Dried 15 parts of rhubarb, 6 parts of honeysuckle, 8 parts of Phellodendron cortex, and 10 parts of mint in the sun, crushed them, added absolute ethanol solution, and ultrasonicated for 3 hours at a power of 1000W to obtain a mixed material, and transferred the mixed material to a reflux device In a three-necked flask in the middle, at 80°C and 3000 rpm, reflux and stir for 2 hours, cool to room temperature, and filter to obtain a Chinese herbal medicine extract;

[0057] (2) Add 3 parts o...

Embodiment 3

[0061] A novel antibacterial and deodorant PVC shoe material, in parts by weight, comprises the following components:

[0062] 20 parts of PVC resin,

[0063] 6 parts of dibutyl phthalate,

[0064] 4 parts of hollow glass microspheres, 9 parts of rhubarb,

[0065] 3 parts of honeysuckle, 2 parts of cork, 6 parts of mint,

[0066] 3 parts of stabilizer, 1 part of crosslinking agent, 4 parts of foaming agent.

[0067] Its preparation method comprises the following steps:

[0068] (1) Dried 9 parts of rhubarb, 3 parts of honeysuckle, 2 parts of Phellodendron cortex, and 6 parts of mint in the sun, crushed them, added absolute ethanol solution, and ultrasonicated for 2.2 hours at a power of 850W to obtain a mixed material, and transferred the mixed material to reflux In the three-necked flask in the device, at 65°C and 2200 rpm, reflux and stir for 1.2h, then cool to room temperature, and filter to obtain the Chinese herbal medicine extract;

[0069] (2) Add 4 parts of hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com