Adjustable Dynamic Rotary Separator for Coal Mills

A dynamic rotation and separator technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of complex structure, separation, inability to function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

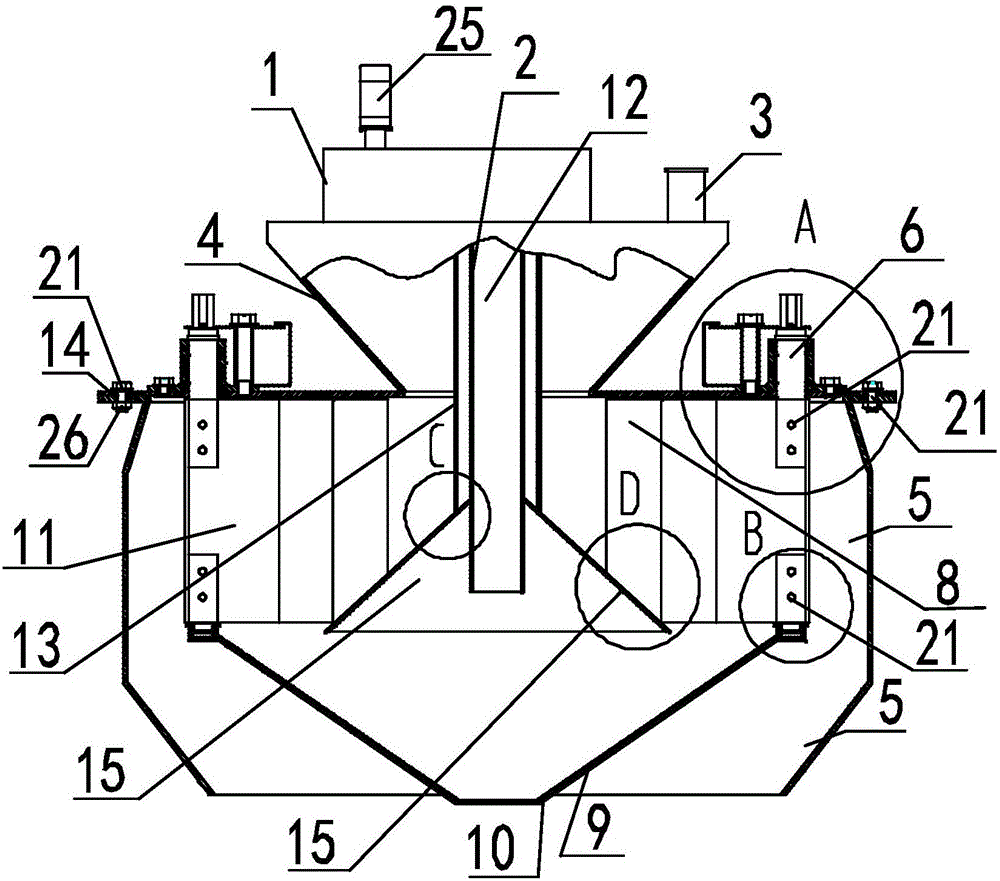

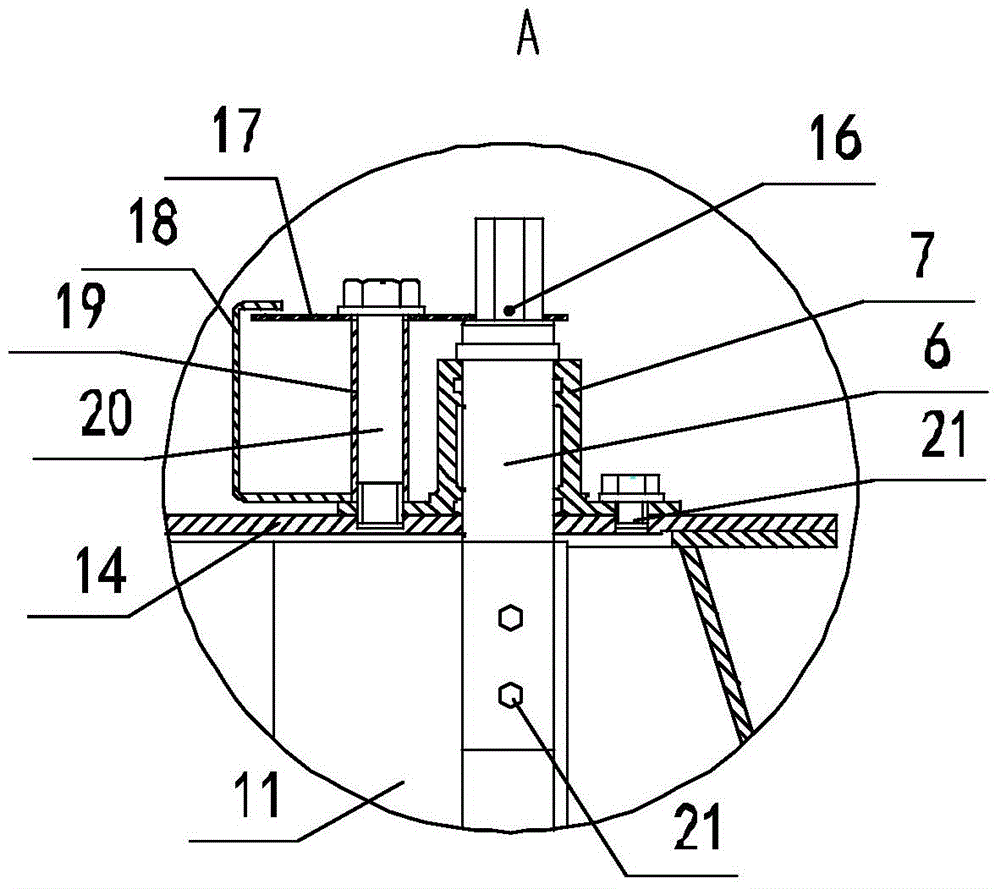

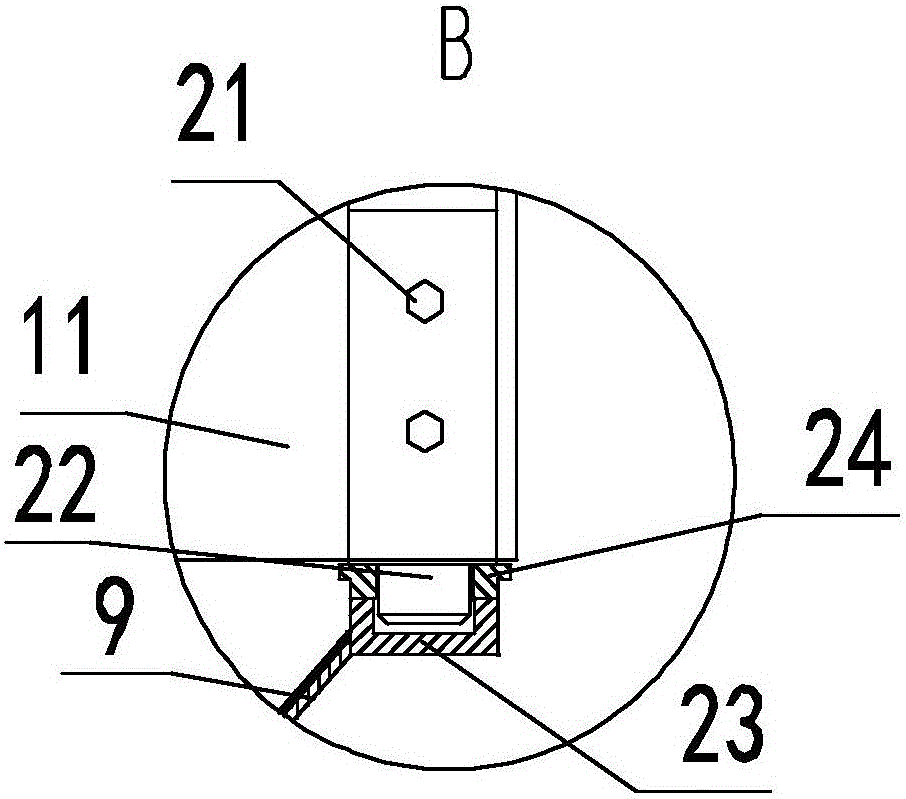

[0005] Including driving part 1, coal falling pipe 2, separator powder outlet pipe 3, distributor 4, housing 5, stationary vane shaft 6, shaft seat 7, moving vane 8, powder returning cone 9, wear-resistant ceramics 10, stationary vane 11. Ceramic lining 12, hollow shaft 13, housing cover plate 14, guide cone 15, elastic cylindrical pin 16, pointer plate 17, pointer 18, sleeve 19, bolt 21, support shaft 22, nut 26, characterized in that: The lower part of the drive part 1 is provided with a distributor 4, the lower part of the distributor 4 is connected to the housing cover 14, the hollow shaft 13 is connected to the guide cone 15; the guide cone 15 is provided with the The moving blade 8 described above. The upper end of the stationary vane shaft 6 is a hexagonal prism, and the elastic cylindrical pin 16 passes through the stationary vane shaft 6 to define the pointer disk 17, and the other end of the stationary vane shaft 6 passes through the hole of the housing cover plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com